About Hex Head Screws and Bolts

More

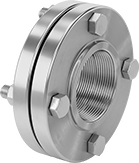

Stainless Steel Hex Screw and Nut Kits for Pipe Flanges

Join standard-sized stainless steel and aluminum pipe flanges in corrosive conditions. These kits come with the right size and number of screws and nuts for the bolt holes in each pipe size. For a tight seal, you’ll also need a gasket between the flanges. All screws and nuts meet ASTM and ASME standards or DIN standards for material quality and dimensions. They may be mildly magnetic. Screw length is measured from under the head.

316 stainless steel fasteners are more corrosion resistant than 18-8 stainless steel fasteners and have excellent resistance to chemicals and salt water.

Screw | Nut | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | For DN Flange Size | Lg., mm | Min. Thread Lg., mm | Head Wd., mm | Head Ht., mm | Tensile Strength, psi | Wd., mm | Ht., mm | No. of Screws Included | No. of Nuts Included | Each | |

18-8 Stainless Steel | ||||||||||||

M12 × 1.75 mm | ||||||||||||

| 1 | 25 | 50 | 30 | 19 | 7.7 | 80,000 | 19 | 10 | 4 | 4 | 000000000 | 00000 |

M16 × 2 mm | ||||||||||||

| 2 | 50 | 55 | 38 | 24 | 10 | 80,000 | 24 | 13 | 4 | 4 | 000000000 | 00000 |

| 3, 4 | 80, 100 | 60 | 38 | 24 | 10 | 100,000 | 24 | 13 | 8 | 8 | 000000000 | 00000 |

316 Stainless Steel | ||||||||||||

M12 × 1.75 mm | ||||||||||||

| 1 | 25 | 50 | 30 | 19 | 7.7 | 80,000 | 19 | 10 | 4 | 4 | 000000000 | 0000 |

M16 × 2 mm | ||||||||||||

| 2 | 50 | 55 | 38 | 24 | 10 | 80,000 | 24 | 13 | 4 | 4 | 000000000 | 00000 |

| 3, 4 | 80, 100 | 60 | 38 | 24 | 10 | 100,000 | 24 | 13 | 8 | 8 | 000000000 | 00000 |

Steel Hex Screw and Nut Kits for Pipe Flanges

Connect standard-sized steel and cast iron pipe flanges. These kits come with the right size and number of screws and nuts for the bolt holes in each pipe size. For a tight seal, you’ll also need a gasket between the flanges. All screws and nuts meet ASTM and ASME standards or DIN standards for material quality and dimensions. Screw length is measured from under the head.

Zinc-plated fasteners resist corrosion in wet environments.

Hot-dipped galvanized fasteners are 10 times more corrosion resistant than zinc-plated fasteners.

Screw | Nut | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Pipe Size | For DN Flange Size | Lg., mm | Min. Thread Lg., mm | Head Wd., mm | Head Ht., mm | Tensile Strength, psi | Wd., mm | Ht., mm | No. of Screws Included | No. of Nuts Included | Each | |

Zinc-Plated Steel | ||||||||||||

M12 × 1.75 mm | ||||||||||||

| 1 | 25 | 50 | 30 | 19 | 7.5 | 110,000 | 19 | 10 | 4 | 4 | 000000000 | 00000 |

M16 × 2 mm | ||||||||||||

| 2 | 50 | 55 | 38 | 24 | 10 | 110,000 | 24 | 13 | 4 | 4 | 000000000 | 00000 |

| 3, 4 | 80, 100 | 60 | 38 | 24 | 10 | 110,000 | 24 | 13 | 8 | 8 | 000000000 | 00000 |

Hot-Dipped Galvanized Steel | ||||||||||||

M16 × 2 mm | ||||||||||||

| 2 | 50 | 55 | 38 | 24 | 10 | 110,000 | 24 | 13 | 4 | 4 | 000000000 | 00000 |

| 3, 4 | 80, 100 | 60 | 38 | 24 | 10 | 110,000 | 24 | 13 | 8 | 8 | 000000000 | 00000 |

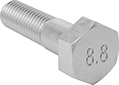

Medium-Strength Class 8.8 Steel Hex Head Screws with Nuts and Washers

Keep compatible screws, nuts, and washers on hand to make a strong joint. Twice as strong as low-strength steel screws, these Class 8.8 steel screws can be used to fasten most machinery and equipment. Washers distribute the pressure from a tightened nut over the surface of your material, which helps prevent damage. A zinc plating helps prevent corrosion in wet environments.

All screws, nuts, and washers meet DIN specifications for material quality and dimensions. Screw length is measured from under the head.

Screw | Nut | Washer | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg., mm | Threading | Min. Thread Lg., mm | Thread Spacing | Head Wd., mm | Head Ht., mm | Tensile Strength, psi | Wd., mm | Ht., mm | ID, mm | OD, mm | Thick., mm | No. of Screws Included | No. of Nuts Included | No. of Washers Included | Each | |

Zinc-Plated Class 8.8 Steel | ||||||||||||||||

M6 × 1 mm | ||||||||||||||||

| 12 | Fully Threaded | __ | Coarse | 10 | 4 | 116,000 | 10 | 5.2 | 6.6 | 12 | 1.8 | 50 | 50 | 100 | 000000000 | 000000 |

| 16 | Fully Threaded | __ | Coarse | 10 | 4 | 116,000 | 10 | 5.2 | 6.6 | 12 | 1.8 | 50 | 50 | 100 | 000000000 | 00000 |

| 20 | Partially Threaded | 18 | Coarse | 10 | 4 | 116,000 | 10 | 5.2 | 6.6 | 12 | 1.8 | 50 | 50 | 100 | 000000000 | 00000 |

| 25 | Partially Threaded | 18 | Coarse | 10 | 4 | 116,000 | 10 | 5.2 | 6.6 | 12 | 1.8 | 50 | 50 | 100 | 000000000 | 00000 |

| 30 | Partially Threaded | 18 | Coarse | 10 | 4 | 116,000 | 10 | 5.2 | 6.6 | 12 | 1.8 | 50 | 50 | 100 | 000000000 | 00000 |

M8 × 1.25 mm | ||||||||||||||||

| 25 | Partially Threaded | 22 | Coarse | 13 | 5.3 | 116,000 | 13 | 6.5 | 8.6 | 16 | 1.8 | 25 | 25 | 50 | 000000000 | 00000 |

| 30 | Partially Threaded | 22 | Coarse | 13 | 5.3 | 116,000 | 13 | 6.5 | 8.6 | 16 | 1.8 | 25 | 25 | 50 | 000000000 | 00000 |

| 35 | Partially Threaded | 22 | Coarse | 13 | 5.3 | 116,000 | 13 | 6.5 | 8.6 | 16 | 1.8 | 25 | 25 | 50 | 000000000 | 00000 |

| 40 | Partially Threaded | 22 | Coarse | 13 | 5.3 | 116,000 | 13 | 6.5 | 8.6 | 16 | 1.8 | 25 | 25 | 50 | 000000000 | 00000 |

M10 × 1.5 mm | ||||||||||||||||

| 25 | Fully Threaded | __ | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 25 | 25 | 50 | 000000000 | 00000 |

| 30 | Partially Threaded | 26 | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 25 | 25 | 50 | 000000000 | 00000 |

| 35 | Partially Threaded | 26 | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 10 | 10 | 20 | 000000000 | 0000 |

| 40 | Partially Threaded | 26 | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 10 | 10 | 20 | 000000000 | 0000 |

| 50 | Partially Threaded | 26 | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 10 | 10 | 20 | 000000000 | 0000 |

| 60 | Partially Threaded | 26 | Coarse | 17 | 6.4 | 116,000 | 17 | 8 | 10.8 | 20 | 2.2 | 10 | 10 | 20 | 000000000 | 00000 |

M12 × 1.75 mm | ||||||||||||||||

| 25 | Fully Threaded | __ | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 0000 |

| 30 | Fully Threaded | __ | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 0000 |

| 35 | Partially Threaded | 30 | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 00000 |

| 40 | Partially Threaded | 30 | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 00000 |

| 50 | Partially Threaded | 30 | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 00000 |

| 60 | Partially Threaded | 30 | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 10 | 10 | 20 | 000000000 | 00000 |

| 100 | Partially Threaded | 30 | Coarse | 19 | 7.5 | 116,000 | 19 | 10 | 13.3 | 24 | 2.7 | 5 | 5 | 10 | 000000000 | 00000 |

Fastener Maintenance Assortments

Black-oxide steel fasteners resist corrosion in dry environments.

Zinc-plated steel fasteners resist corrosion in wet environments.

18-8 stainless steel fasteners are chemical resistant and may be mildly magnetic.

| Number of Pieces | Includes | Drive Style | Specifications Met | Container Type | Each | |

Metric | ||||||

|---|---|---|---|---|---|---|

Zinc-Plated and Black-Oxide Steel | ||||||

| 7,060 | 570 Socket Head Screws (M4 to M12) 750 Rounded Head Screws (M3 to M6) 580 Hex Head Screws (M4 to M12) 60 Set Screws (M4 to M6) 1,475 Hex Nuts (M3 to M12) 1,225 Flat Washers (For M4 to M12 Screw Sizes) 1,600 Lock Washers (For M3 to M12 Screw Sizes) 800 Spring Lock Washers (For M4 to M8 Screw Sizes) | External Hex, Hex, Phillips | DIN 125, DIN 127B, DIN 7985, DIN 912, DIN 916, DIN 933, DIN 934 | Metal Drawer Cabinet | 000000000 | 000000000 |

18-8 Stainless Steel | ||||||

| 7,060 | 570 Socket Head Screws (M4 to M12) 750 Rounded Head Screws (M3 to M6) 580 Hex Head Screws (M4 to M12) 60 Set Screws (M4 to M6) 1,475 Hex Nuts (M3 to M12) 1,225 Flat Washers (For M4 to M12 Screw Sizes) 1,600 Lock Washers (For M3 to M12 Screw Sizes) 800 Spring Lock Washers (For M4 to M8 Screw Sizes) | External Hex, Hex, Phillips | DIN 125, DIN 127B, DIN 7985, DIN 912, DIN 916, DIN 933, DIN 934 | Metal Drawer Cabinet | 000000000 | 00000000 |

Hex Head Screw Assortments

These assortments include hex head screws and hex nuts. Length is measured from under the head.

Grade 5 and Class 8.8 steel screws are suitable for fastening most machinery and equipment. Zinc-plated steel screws resist corrosion in wet environments.

| Number of Pieces | Includes | Specifications Met | Container Type | Each | |

Metric | |||||

|---|---|---|---|---|---|

Class 8.8 Steel | |||||

| 2,295 | 765 Hex Head Screws (M4 to M12 in 10 mm to 60 mm Lengths) 765 Hex Nuts (M4 to M12) 765 Lock Washers (For M4 to M12 Screw Sizes) | DIN 933, DIN 934, DIN 127B | Metal Box and Plastic Box | 000000000 | 0000000 |

Zinc-Plated Class 8.8 Steel | |||||

| 465 | 315 Hex Head Screws (M4 to M10 in 12 mm to 50 mm Lengths) 150 Hex Nuts (M4 to M10) | DIN 933, DIN 934 | Plastic Box | 000000000 | 000000 |

| 2,295 | 765 Hex Head Screws (M4 to M12 in 10 mm to 60 mm Lengths) 765 Hex Nuts (M4 to M12) 765 Lock Washers (For M4 to M12 Screw Sizes) | DIN 933, DIN 934, DIN 127B | Metal Box and Plastic Box | 000000000 | 000000 |