Carbide Inserts for Multiple Materials

Choose these premium carbide inserts to turn a variety of materials without changing out your tool. They’re made of higher-quality carbide than economy inserts, so they last longer and create a smoother finish. Install them into a matching holder. For the best performance, choose an insert designed for the material of your workpiece.

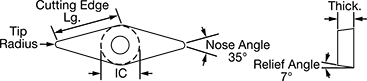

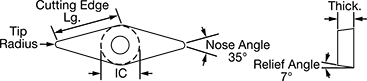

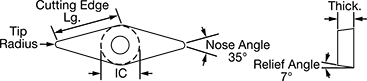

Inserts with a larger nose angle and tip radius remove more material with each pass, but they cut less precisely than smaller inserts. Select the insert with the largest nose angle and tip radius that will turn your workpiece to the shape you want.

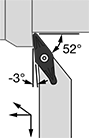

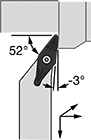

Inserts for semi-interrupted cutting conditions are used to machine imperfectly round workpieces, such as shafts with a keyway. They’re the most common type of insert. Positive-rake inserts stick out in front of the holder to reach tight spaces on the workpiece. However, they only have cutting edges on one side.

Medium inserts remove a moderate amount of material for a semi-smooth surface finish.

Inserts with a titanium aluminum nitride (TiAlN) coating dissipate heat well, especially at high speeds. The coating reacts to high temperatures by forming a layer of aluminum oxide. This layer transfers heat to the chips, so the tool stays cool even without lubrication.

Inserts with chip breakers prevent long chips from forming, so they won’t block the flow of coolant or damage your tool.

Inserts sold in packs come factory sealed from the manufacturer for maximum traceability. Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment.

Each | Package | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insert Code | Inscribed Circle Dia. (IC) | Tip Radius | Thick. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Features | Each | Pkg. Qty. | Pkg. | ||

For Use On Aluminum, Brass, Bronze, Copper, Nickel, Plastic, Stainless Steel, Steel | |||||||||||||

For Semi-Interrupted Cutting Conditions | |||||||||||||

| VCGT-220.5 | 1/4" | 0.008" | 1/8" | 0.43" | Positive | Medium | Titanium Aluminum Nitride (TiAlN) Coated | Chip Breakers | 00000000 | 000000 | 10 | 00000000 | 0000000 |

| VCGT-221 | 0.160" | 1/64" | 1/8" | 0.42" | Positive | Medium | Titanium Aluminum Nitride (TiAlN) Coated | Chip Breakers | 00000000 | 00000 | 10 | 00000000 | 000000 |

Precision Carbide Inserts for Stainless Steel and Heat-Resistant Super Alloys

Strong enough for use on titanium, stainless steel, and other tough metals, a PVD coating keeps these inserts sharp for longer than inserts with a CVD coating. Also known as Swiss lathe tools, they’re designed for use in precision lathes. Install them into a matching holder.

These inserts are meant for semi-interrupted cutting conditions. As the most common insert type, they often machine imperfectly round workpieces, like shafts with a keyway. They also have a positive rake, which means they stick out in front of the holder to reach tight spaces on your workpiece. However, they don’t last as long as negative rake inserts because they have cutting edges on only one side. Since these inserts have a 0° lead angle, or a neutral cut direction, they can cut from either right to left or left to right.

Inserts with a larger nose angle and tip radius remove more material with each pass but cut less precisely than smaller inserts. Select the insert with the largest nose angle and tip radius that will turn your workpiece to the desired shape.

Use finishing inserts at the end of your turning process to remove minimal material for a smooth finish.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

| Insert Code | Inscribed Circle Diameter (IC) | Tip Radius | Thick. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Each | |

For Semi-Interrupted Cutting Conditions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| VCGT-220.2 | 1/4" | 0.004" | 1/8" | 0.43" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 0000000 | 000000 |

| VCGT-220.5 | 1/4" | 0.008" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 0000000 | 00000 |

| VCGT-221 | 1/4" | 1/64" | 1/8" | 0.4" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 0000000 | 00000 |

| Insert Code | Inscribed Circle Diameter (IC) | Tip Radius | Thick. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Pkg. Qty. | Pkg. | |

For Semi-Interrupted Cutting Conditions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VCGT-220.2 | 1/4" | 0.004" | 1/8" | 0.43" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 10 | 0000000 | 0000000 |

| VCGT-220.5 | 1/4" | 0.008" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 10 | 0000000 | 000000 |

| VCGT-221 | 1/4" | 1/64" | 1/8" | 0.4" | Positive | Finishing | Aluminum Titanium Chromium Nitride (AlTiCrN) Coated | 10 | 0000000 | 000000 |

Precision Carbide Inserts for Steel

Also known as Swiss lathe tools, these inserts are designed for use in precision lathes. Coated in multiple layers of PVD, they stay sharper longer than CVD-coated inserts. They’re optimized for steel but also work on stainless steel. Install inserts into a matching holder.

These inserts are meant for semi-interrupted cutting conditions. As the most common insert type, they often machine imperfectly round workpieces, like shafts with a keyway. They have a positive rake, meaning they stick out in front of the holder to reach tight spaces on the workpiece. However, they don’t last as long as negative rake inserts because they have cutting edges on only one side. Since these inserts have a 0° lead angle, or a neutral cut direction, they can cut from either right to left or left to right.

Inserts with a larger nose angle and tip radius remove more material with each pass but cut less precisely than smaller inserts. Select the insert with the largest nose angle and tip radius that will still turn your workpiece to the desired shape.

Use finishing inserts at the end of your turning process to remove minimal material for a smooth finish.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer, for maximum traceability.

| Insert Code | Inscribed Circle Dia. (IC) | Tip Radius | Thick. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Each | |

For Semi-Interrupted Cutting Conditions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| VCGT-220.2 | 1/4" | 0.004" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 0000000 | 000000 |

| VCGT-220.5 | 1/4" | 0.008" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 0000000 | 00000 |

| VCGT-221 | 1/4" | 1/64" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 0000000 | 00000 |

| Insert Code | Inscribed Circle Dia. (IC) | Tip Radius | Thick. | Cutting Edge Lg. | Rake Type | For Cutting Operation | Finish | Pkg. Qty. | Pkg. | |

For Semi-Interrupted Cutting Conditions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VCGT-220.2 | 1/4" | 0.004" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 10 | 0000000 | 0000000 |

| VCGT-220.5 | 1/4" | 0.008" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 10 | 0000000 | 000000 |

| VCGT-221 | 1/4" | 1/64" | 1/8" | 0.42" | Positive | Finishing | Aluminum Titanium Nitride (AlTiN) Coated | 10 | 0000000 | 000000 |

Turning Carbide Insert Holders

Secure carbide inserts inside these holders for stable turning. They’re also known as indexable insert holders. Select a holder that’s compatible with your insert by matching the insert style and inscribed circle diameter (IC). Right-hand holders move from right to left toward the lathe chuck, left-hand holders move from left to right away from the lathe chuck, and neutral holders can cut in either direction.

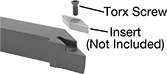

S-code holders secure inserts with a screw for easy indexing. They’re the most commonly used holders with positive-rake inserts.

Holders with an offset shank are good for reaching into tight corners and when working close to the chuck.

Holders | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Insert | Shank | Replacement Torx Screws | Replacement Torx Keys | |||||||

| Inscribed Circle Dia. (IC) | Thick. | Wd. | Ht. | O'all Lg. | Each | Each | Each | |||

For Along-the-Length Turning, Chamfering, External Profiling | ||||||||||

Right Hand | ||||||||||

| 1/4" | 1/8" | 5/8" | 5/8" | 4" | 00000000 | 0000000 | 00000000 | 00000 | 0000000 | 00000 |

| 3/8" | 3/16" | 3/4" | 3/4" | 4 1/2" | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 0000 |

| 3/8" | 3/16" | 1" | 1" | 6" | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 0000 |

Left Hand | ||||||||||

| 3/8" | 3/16" | 3/4" | 3/4" | 4 1/2" | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 0000 |

| 3/8" | 3/16" | 1" | 1" | 6" | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 0000 |