How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

Liquid Samplers

Steel with

Pull Ring

Collect liquid samples from drums, tanks, and other containers. These samplers open and close, so you can gather samples at a targeted depth in your tank. All are autoclavable, so you can sterilize them with steam.

Stainless steel samplers are the most durable and chemical resistant. They also resist corrosion. Less porous and less likely to scratch than plastic, they’re easy to sanitize. Open and close them by pulling up on the center ring.

Sanitary Sampling Valves

- Valve Type: Stop Cock

- For Use With: Food, Beverage

- Specifications Met: FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 177.1550

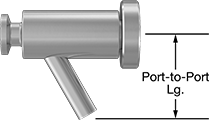

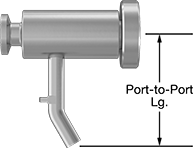

Take liquid samples in sanitary environments—these sampling valves have a hygienic design, so they’re commonly used in breweries and wineries. With a body made of 316 stainless steel and a PTFE plastic seat, they resist the high temperatures and harsh chemicals of clean-in-place (CIP) processes. These valves have an extremely smooth surface, leaving no space for bacteria to grow. Quick-clamp connections, also known as tri-clamp fittings, are easily taken apart for regular cleaning. These valves are self-draining, so previous samples and cleaning chemicals won’t contaminate future samples. Both the seat and the silicone O-ring comply with FDA standards for direct contact with food and beverage.

To take samples, turn the thumb screw to open valves. Hang a bucket for sample collection from the bucket groove. Valves also have a leak detection port that will release a small amount of liquid to let you know when it’s time to replace all the valve seals.

Valves with a bent spout have a tab for connecting carbon dioxide testing devices. They’re often used for carbonated beverages. They shouldn’t be used with liquids that have solids in them, such as the grape skins or seeds in wine, as those can get caught in the outlet.

Inlet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Sampling Outlet Spout OD | Flow Pattern | Maximum Pressure | Temperature Range, °F | End-to-End Lg. | Port-to-Port Lg. | Surface Smoothness | Each | |

Quick Clamp Inlet—Straight Sampling Outlet Spout | ||||||||||

316 Stainless Steel | ||||||||||

| 1/2" | 0.984" | 1/2" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 1 15/16" | 32 microinch | 0000000 | 0000000 |

| 1" | 2" | 1/2" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 1 15/16" | 32 microinch | 0000000 | 000000 |

Quick Clamp Inlet—Bent Sampling Outlet Spout with Tab | ||||||||||

316 Stainless Steel | ||||||||||

| 1/2" | 0.984" | 13/32" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 2 3/4" | 32 microinch | 0000000 | 000000 |

| 1" | 2" | 13/32" | L-Pattern | 145 psi @ 70° F | -40° to 450° | 3 5/16" | 2 3/4" | 32 microinch | 0000000 | 000000 |

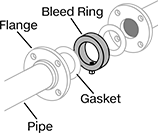

Stainless Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Create an access point in a pipe line where corrosion is a concern. Often used to relieve pressure or siphon and sample liquids, these bleed rings act as a port between two pipe flanges, eliminating the need to take apart your flanges to get inside. They include a plug, or replace the plug with your own fitting, valve, or probe. Made of stainless steel, these bleed rings resist rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

304 stainless steel bleed rings keep corrosion at bay in wet conditions but will start to corrode when exposed to salt water. 316 stainless steel bleed rings withstand wet conditions as well as chemicals and salt water.

Plug | 304/304L Stainless Steel | 316/316L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | Each | ||

For Flange Class 125 or 150 | ||||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

For Flange Class 300 | ||||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

For Flange Class 600 | ||||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

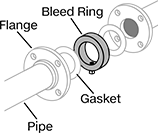

Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Access the inside of a pipe line to vent pressure, drain liquid, or take samples. These bleed rings act as a port where two pipe flanges meet, so you don’t have to disassemble your flanges to get inside. They include a plug, or you can attach your own fitting, valve, or probe. Made of steel, these bleed rings should be used in noncorrosive environments to prevent rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

Plug | Steel | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | |

For Flange Class 125 or 150 | ||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 300 | ||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 600 | ||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |