What is the Difference Between Copper, Brass, and Bronze?

Choose from our selection of copper, brass, and bronze. In stock and ready to ship.

Although copper, brass, and bronze are distinct alloys, they’re often collectively called red metals because they share many common characteristics. These alloys have a high copper content that provides inherent corrosion resistance as well as an attractive russet coloring. Red metals are worked (wrought) or cast into shape and are commonly joined by soldering or brazing; however, some can be welded.

- Copper alloys have a minimum of 99.3% copper content. They are excellent conductors of heat and electricity and are commonly used for bus bars and wire connectors in electrical applications.

- Brass alloys consist primarily of copper, but they can contain as much as 40% zinc, which increases their machinability. They are often used for nuts, rivets, hinges, and locks.

- Bronze alloys, while mostly copper, contain small amounts of tin, iron, and sometimes zinc. The alloys designated as bearing bronze have a good combination of low friction and high wear resistance, making them the best choice for use as bearings. The other bronze alloys are widely used for gears, valves, and pump parts.

Alloy Comparison

Use the charts below to identify the best material for your application. Good and excellent ratings indicate that a majority of a material’s shapes and sizes meet the applicable rating. Blank boxes indicate a poor rating or no rating. Yield strength is approximate and may vary by size and shape.

| Alloy Types | Min. Yield Strength, psi | Hardness (Rockwell) | Machinability | Formability | Electrical Conductivity | Weldability |

|---|---|---|---|---|---|---|

| Copper | ||||||

| Multipurpose 110 | 33,000 | F40 | Excellent | Excellent | ||

| Super-Conductive 101 and 102 | 10,000 | F60 | Excellent | Excellent | Good | |

| Easy-to-Machine 145 | 18,000 | ___ | Excellent | Good | Excellent | |

| High Strength 182 | 40,000 | B60 | Excellent | Good | ||

| Weldable 122 | _____ | ___ | Excellent | Good | Good | |

| Brass | ||||||

| Ultra-Machinable 360 | 15,000 | B35 | Excellent | |||

| Formable Easy-to-Machine 353 | 25,000 | B60 | Excellent | Good | ||

| Easy-to-Machine Architectural 385 | 16,000 | B42 | Excellent | |||

| Ultra-Formable 260 | _____ | ___ | Excellent | Good | ||

| High-Strength 330 | 60,000 | B73 | Good | Excellent | ||

| Weldable Marine-Grade 464 | 20,000 | B55 | Good | Good | ||

| Marine-Grade 485 | 25,000 | B60 | Good | |||

| Bearing Bronze | ||||||

| 932 Bearing Bronze | 18,000 | B34 | Good | |||

| Easy-to-Machine 936 | 21,000 | B26 | Good | |||

| Weldable 954 | 28,800 | B80 | Good | Good | ||

| Ultra-Wear-Resistant AMPCO 18 | 37,000 | B88 | Good | Good | ||

| High-Strength 863 | 62,000 | B97 | ||||

| High-Strength Formable 544 | 50,000 | ___ | Good | Good | ||

| Self-Lubricating Oil-Filled 840 and 841 | 11,000 | ___ | Good | |||

| High-Temperature Graphite-Filled 841 | 8,500 | ___ | Good | |||

| Bronze | ||||||

| High-Strength 630 | 50,000 | B90 | Good | |||

| Easy-to-Machine High-Strength 642 | 42,000 | B65 | Good | |||

| Easy-to-Weld 655 | 43,000 | B75 | Excellent | Excellent | ||

| Easy-to-Machine 316 | 28,000 | B70 | Good | Good | ||

| Easy-to-Form 220 | 33,000 | B55 | Excellent | Good | ||

| Ultra-Strength Easy-to-Form 510 | 80,000 | ___ | Excellent | Good | ||

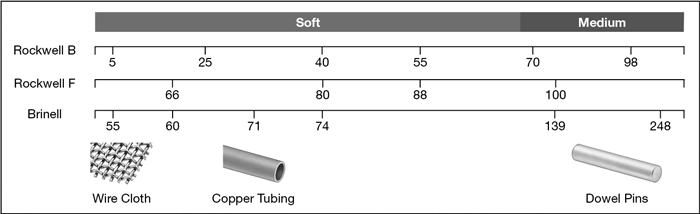

Hardness Comparison

The chart below compares the hardness of metals using different scales; the larger the number, the harder the material. As metal gets harder, it becomes more wear resistant, but may also become less malleable. Red metals generally fall onto the soft end of the spectrum.

Choose from our selection of copper, brass, and bronze. In stock and ready to ship.