How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

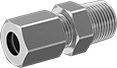

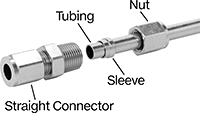

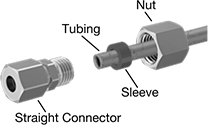

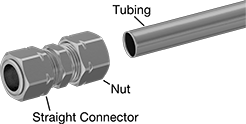

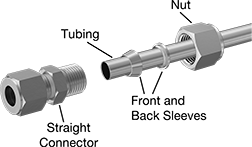

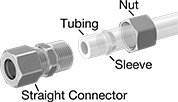

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing:

Inch:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 18mm | 1.5 to 2.5 mm | 3/4 | 316 Stainless Steel | 2,900 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | 1.5 to 2.5 mm | 316 Stainless Steel | 2,100 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | 1.5 to 2.5 mm | 316 Stainless Steel | 2,900 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | 1.5 to 2.5 mm | 316 Stainless Steel | 2,900 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 18mm | 1.5 to 2.5 mm | 316 Stainless Steel | 7mm | 1 | 4mm | 1 | 2,900 psi @ 72° F | 00000000 | 000000 |

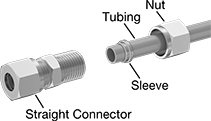

Compression Fittings for Stainless Steel Tubing

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings or bite fittings. Use them in low- to medium-pressure applications.

316 stainless steel fittings have excellent corrosion resistance.

ISO and DIN fittings meet international dimensional standards.

- For Use With:

303 Stainless Steel, 316 Stainless Steel with 17-4 PH Stainless Steel Sleeve, and 360 Brass: Air, Water, Hydraulic Fluid

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range: See table

- Tubing: See table

- Specifications Met:

316 Stainless Steel: ISO 8434, DIN 2353

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: SAE J514

For Tube | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Gasket Material | Sleeve Material | Max. Pressure | Temp. Range, °F | For Tube Material | For Tube Specifications Met | For Tube Fabrication | Each | |

NPT Threads | ||||||||||||

| 18mm | 1.5-2mm | 1/2 | 316 Stainless Steel | __ | 316 Stainless Steel | 4,500 psi @ 72° F | -75° to 750° | 304 Stainless Steel, 316/316L/316Ti Stainless Steel | DIN EN 10216-5, DIN EN 10305-1 | Seamless | 00000000 | 000000 |

| 18mm | 1.5-2mm | 3/4 | 316 Stainless Steel | __ | 316 Stainless Steel | 4,500 psi @ 72° F | -75° to 750° | 304 Stainless Steel, 316/316L/316Ti Stainless Steel | DIN EN 10216-5, DIN EN 10305-1 | Seamless | 00000000 | 00000 |

BSPP Threads | ||||||||||||

| 18mm | 1.5-2mm | 1/2 | 316 Stainless Steel | Fluoroelastomer Rubber | 316 Stainless Steel | 5,800 psi @ 72° F | -10° to 390° | 304 Stainless Steel, 316/316L/316Ti Stainless Steel | DIN EN 10216-5, DIN EN 10305-1 | Seamless | 00000000 | 00000 |

| 18mm | 1.5-2mm | 3/4 | 316 Stainless Steel | Fluoroelastomer Rubber | 316 Stainless Steel | 5,800 psi @ 72° F | -10° to 390° | 304 Stainless Steel, 316/316L/316Ti Stainless Steel | DIN EN 10216-5, DIN EN 10305-1 | Seamless | 00000000 | 00000 |

- For Use With:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: Air, Water, Hydraulic Fluid

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: -420° to 1200° F

316 Stainless Steel: -75° to 750° F - Tubing:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A269

316 Stainless Steel: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1 - Specifications Met:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: SAE J514

316 Stainless Steel: ISO 8434, DIN 2353

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Sleeve Material | Max. Pressure | Each | |

| 18mm | 1.5-2mm | 316 Stainless Steel | 316 Stainless Steel | 5,800 psi @ 72° F | 0000000 | 000000 |

- For Use With:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: Air, Water, Hydraulic Fluid

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: -420° to 1200° F

316 Stainless Steel: -75° to 750° F - Tubing:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A269

316 Stainless Steel: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1 - Specifications Met:

316 Stainless Steel with 17-4 PH Stainless Steel Sleeve: SAE J514

316 Stainless Steel: ISO 8434, DIN 2353

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Sleeve Material | Max. Pressure | Each | |

| 18mm | 1.5-2mm | 316 Stainless Steel | 316 Stainless Steel | 5,800 psi @ 72° F | 0000000 | 000000 |

- For Use With: See table

- Temperature Range: See table

- Tubing: See table

- Specifications Met: See table

For Tube | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | For Use With | Temp. Range, °F | For Tube Material | For Tube Specifications Met | For Tube Fabrication | Specifications Met | Each | |

| 18mm | 1.5-2mm | 316 Stainless Steel | 5,800 psi @ 72° F | Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water | -75° to 750° | 304 Stainless Steel, 316/316L/316Ti Stainless Steel | DIN EN 10216-5, DIN EN 10305-1 | Seamless | DIN 2353, ISO 8434-1 | 0000000 | 000000 |

- For Use With:

17-4 PH Stainless Steel: Air, Hydraulic Fluid, Water

316 Stainless Steel: Air, Cutting Oil, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Mineral Oil, Natural Gas, Steam, Water - Temperature Range:

17-4 PH Stainless Steel: -420° to 1200° F

316 Stainless Steel: -75° to 750° F - Tubing:

17-4 PH Stainless Steel: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A269

316 Stainless Steel: Use with seamless 304 or 316/316L/316Ti stainless steel that meets DIN EN 10216-5 or DIN EN 10305-1 - Specifications Met:

17-4 PH Stainless Steel: SAE J514

316 Stainless Steel: ISO 8434-1, DIN 2353

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Max. Pressure | Each | |

| 18mm | 1.5-2mm | 316 Stainless Steel | 5,800 psi @ 72° F | 0000000 | 00000 |

Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Compressed Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Helium, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Instead of a metal sleeve (ferrule), these fittings have a rubber sleeve that cushions tubing and absorbs vibration to maintain a tight seal, even when connected to large pumps. However, rubber sleeves can’t withstand temperatures as high as metal ones. To create the strong seal, tighten the included nut. These fittings are made of 316 stainless steel, so they have excellent corrosion resistance. They’re also known as flareless fittings. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Material | Maximum Pressure | Each | |

NPT Threads | ||||||

| 18 | 2 | 1/2 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 0000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 18 | 2 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 000000 |

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Drinking Water

- Tubing: See table

- Specifications Met: See table

Fittings with center stop have a small internal ridge that prevents the tubing from sliding all the way through the fitting.

Fittings that meet ASTM B379 comply with international standards for tube fitting specifications.

| For Tube OD | Material | Max. Pressure | For Copper Tube Type | Specifications Met | Each | |

| 18mm | Copper | 500 psi @ 72° F | M | ASTM B379, DVGW GW 8, EN 1057 | 00000000 | 00000 |

- For Use With: Drinking Water

- Tubing: See table

- Specifications Met: See table

Fittings that meet ASTM B379 comply with international standards for tube fitting specifications.

| For Tube OD | Material | Max. Pressure | For Copper Tube Type | Specifications Met | Each | |

| 18mm | Copper | 500 psi @ 72° F | M | ASTM B379, DVGW GW 8, EN 1057 | 00000000 | 00000 |

Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: See Table

- Tubing: Use with copper

- Specifications Met: See Table

Create a strong connection without heating, flaring, or soldering. These fittings have a single sleeve (ferrule or olive) that bites into tubing as you tighten the nut. Both the nut and sleeve are included. Also known as single ferrule fittings, they are easier to install than yor-lok fittings which have two ferrules. They’re often used in low to medium pressure applications, such as plumbing and compressed air systems, which don’t require the strength of a yor-lok fitting. Compression fittings for copper tubing can withstand higher pressures than compression fittings for plastic and rubber tubing. Made of brass, they have good corrosion resistance.

To connect a compression fitting to tube, slide the nut and sleeve onto the tube. Then push the tube into the fitting until it butts against the back of the fitting. Tighten the nut onto the fitting to compress the sleeve.

Threaded connections can be taken apart as needed for maintenance and repair.

Nickel-Plated Brass Compression Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Ethyl Alcohol, Fuel Oil, Gasoline, Hydraulic Fluid, Isopropyl Alcohol, Lubricants, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -75° to 550° F, except 90° elbow adapters with BSPP threads are 0° to 170° F

- Tubing: Use with copper

- Specifications Met: DIN 3861, except nuts meet DIN 3870

With a nickel-plated finish, these compression fittings resist corrosion better than plain brass fittings. They have a single sleeve (ferrule) made of plain brass that gently bites into copper tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. These fittings are also known as flareless fittings. All meet DIN standards for tube fitting dimensions.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Material | Maximum Pressure | Each | |

BSPT Threads | ||||||

| 18 | 1 | 1/2 | Nickel-Plated Brass | 900 psi @ 72° F | 00000000 | 000000 |

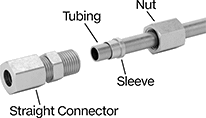

Compression Fittings for Steel Tubing

(SAE Straight) Male

Threads with Gasket

Threads with

Gasket and Washer

- For Use With: Inch: Air, Hydraulic Fluid, Water

Metric: Hydraulic Fluid - Tubing: Inch: Use with welded steel

Metric: Use with seamless steel - Specifications Met: Inch: SAE J514

Metric: ISO 8434, DIN 2353

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless and bite fittings.

Zinc-plated steel fittings have fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads. BSPP male threads have either a gasket or a gasket and washer to prevent leaks. ISO 8434 (formerly DIN 2353) fittings meet international standards for tube fitting pressures.

(SAE Straight) Male

Threads with Gasket

- Temperature Range: -20° to 230° F

Fittings that swivel until tightened rotate 360° for easy installation.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thick. | Pipe Size | Material | Gasket Material | Max. Pressure | Each | |

BSPP Threads | |||||||

| 18 | Not Rated | 1/2 | Zinc-Plated Steel | Buna-N Rubber | 3,600 psi @ 72° F | 0000000 | 000000 |

- Temperature Range: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | Not Rated | Zinc-Plated Steel | 3,600 psi @ 72° F | -20° to 230° | 00000000 | 000000 |

Threads with

Gasket and Washer

- Temperature Range: See table

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Gasket Material | Washer Material | Max. Pressure | Temp. Range, °F | Each | |

BSPP Threads | |||||||||

| 18mm | Not Rated | 1/2 | Zinc-Plated Steel | Buna-N Rubber | Steel | 3,600 psi @ 72° F | -20° to 230° | 0000000 | 000000 |

- Temperature Range: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | Not Rated | Zinc-Plated Steel | 3,600 psi @ 72° F | -20° to 230° | 00000000 | 000000 |

- Temperature Range: -20° to 230° F

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thick. | Material | Max. Pressure | Each | |

| 18 | Not Rated | Zinc-Plated Steel | 3,600 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: See table

| For Tube OD | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | Zinc-Plated Steel | 3,600 psi @ 72° F | -20° to 230° | 00000000 | 00000 |

- Temperature Range: See table

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | Zinc-Plated Steel | 3,600 psi @ 72° F | -20° to 230° | 00000000 | 00000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

NPT Threads | ||||||||

| 18mm | 1.5mm | 3/4 | Zinc-Plated Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 000000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 18mm | 1.5mm | Zinc-Plated Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 18mm | 1.5mm | Zinc-Plated Steel | 316 Stainless Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

Nuts for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: See table

- Tubing: Use with seamless steel

- Specifications Met: See table

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on steel tubing. They are zinc-plated steel for fair corrosion resistance.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 18mm | 1.5mm | Zinc-Plated Steel | 2,700 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

Front and Back Sleeves for Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Mineral Oil, Fuel Oil, Gasoline, Diesel Fuel, Cutting Oil, Hydraulic Fluid

- Temperature Range: -20° to 800° F

- Tubing: Use with seamless steel

- Specifications Met: ASME B31.3

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on steel tubing. They are also known as ferrules.

Zinc-plated steel sleeves have fair corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Each | |

| 18mm | 1.5mm | Zinc-Plated Steel | 316 Stainless Steel | 2,700 psi @ 72° F | 00000000 | 00000 |

Brass Compression Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water

- Temperature Range: See table

- Tubing: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic or polyurethane rubber

- Specifications Met: SAE J512, except metric sizes

A single sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

Use tube supports (sold separately) when attaching fittings to plastic and rubber tubing to prevent the tube from collapsing.

BSPP male threads have an O-ring to protect against leaks.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | O-Ring Material | Max. Pressure | Temp. Range, °F | Each | |

BSPT Threads | ||||||||

| 18mm | 1mm | 1/2 | Brass | __ | 1000 psi @ 72° F | -75° to 550° | 00000000 | 00000 |

BSPP Threads | ||||||||

| 18mm | 1mm | 1/2 | Brass | Buna-N Rubber | 1000 psi @ 72° F | 0° to 175° | 00000000 | 00000 |

| 18mm | 1mm | 3/4 | Brass | Buna-N Rubber | 1000 psi @ 72° F | 0° to 175° | 00000000 | 00000 |

- Temperature Range: -75° to 550° F

- Tubing: Use with hard or firm (Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

For Tube | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Max Pressure | Each | |

| 18mm | 15mm | Brass | 1000 psi @ 72° F | 00000000 | 00000 |

- For Use With:

Short nuts: Air, Water, Lubricated Air

Long nuts: Air, Water, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil - Temperature Range: See table

- Tubing:

Short nuts: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

Long nuts: Use with firm or hard (Durometer 1A-95A) copper, nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber - Specifications Met: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

Short Nuts | ||||||

| 18mm | 1mm | Brass | 1000 psi @ 72° F | -75° to 550° | 00000000 | 00000 |

- For Use With:

UL Listed sleeves: Air, Water, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

All other sleeves: Air, Water, Lubricated Air - Temperature Range: See table

- Tubing:

UL Listed sleeves: Use with firm or hard (Durometer 1A-95A) copper, nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

All other sleeves: Use with firm or hard (Durometer 1A-95A or Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber - Specifications Met: See table

For Tube | Sleeve | |||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 18mm | 1mm | Brass | 1000 psi @ 72° F | -75° to 550° | 00000000 | 00000 |

- For Use With: Air, Lubricated Air, Water

- Temperature Range: -20° to 212° F

| For Pipe Size | For Thread Type | For Gender | O-Ring Material | Max. Pressure | Each | |

| 3/4 | BSPP | Male | Buna-N Rubber, Steel | 1000 psi @ 72° F | 000000000 | 00000 |

Tube Supports for Brass Compression Tube Fittings for Air and Water

Use these sleeves with brass compression nuts and fittings to create a seal on plastic and rubber tubing. They are brass, so they won’t damage tubing.

- Temperature Range:

Inch: -65° to 250° F

Metric: -40° to 250° F - Tubing:

Tube supports with 135 psi @ 75° F or 165 psi @ 75° F max. pressures: Use with firm or soft polyethylene plastic or PVC plastic

Tube supports with all other max. pressures: Use with firm or soft (Durometer 1A-95A) polyethylene plastic or polypropylene plastic

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Max. Pressure | Pkg. Qty. | Pkg. | |

| 18mm | 14mm | Brass | 530 psi @ 72° F | 1 | 000000000 | 00000 |

- Temperature Range: -75° to 550° F

- Tubing: Use with hard or firm (Rockwell 15T 1-15T 60) nylon plastic, polyethylene plastic, polypropylene plastic, or polyurethane rubber

For Tube, mm | |||||

|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Max. Pressure | Each | |

| 18 | 15 | Brass | 1000 psi @ 72° F | 00000000 | 00000 |

Push-to-Connect Tube Fittings for Drinking Water

with

Gasket

- Temperature Range: 35° to 150° F

- Tubing: See table

- Specifications Met: NSF/ANSI 61

Made of moisture-resistant acetal, these fittings won't absorb water and lose strength, even in high-humidity environments. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. All meet NSF/ANSI 61 for use in drinking water systems.

BSPP male threads have a gasket to protect against leaks.

with

Gasket

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Color | Gasket Material | Release Ring Color | Max. Pressure | Material | Each | |

BSPP Threads | |||||||||

| 18mm | 1/2 | Acetal Plastic | Black | Buna-N Rubber | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 0000000 | 00000 |

Fittings with tube stem insert into the push-to-connect end of another fitting in place of a length of tubing.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| Tube Stem OD | For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

| 22mm | 18mm | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

| 18mm | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

| 18mm | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

| 18mm | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 00000 |

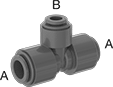

Inline tees are also known as branch tees.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD (A) | For Tube OD (B) | Material | Color | Release Ring Color | Max. Pressure | Material | Each | |

| 18mm | 15mm | Acetal Plastic | Black | Black | 150 psi @ 72° F | Nylon Plastic, Polyethylene Plastic | 00000000 | 000000 |

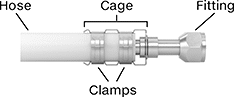

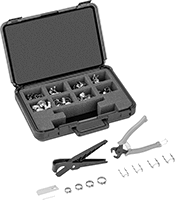

Refrigerant Hose Fittings

- Maximum Pressure: 500 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -40° to 280° F

- Compatible With: Danfoss EZ Clip

- All Fittings Swivel Until Tightened

- Specifications Met: SAE J2064, SAE J3062

- Compatible Hose: Refrigerant Hose

No need for expensive crimping tools—these fittings make air conditioning and refrigeration assemblies with clamps. Instead of a crimper, they use two clamps that you tighten against a cage on your fitting with pliers. Both fitting ends swivel until tightened, so you don't have to rotate the entire hose during installation. The cage and clamps stretch out after use, so they shouldn't be used again.

Straight adapter kits include everything you need to connect one end to aluminum tubing. Braze the fitting to your tube with one of the braze rings. To prevent leaks, slip an O-ring on after the brazed joint cools. To connect these fittings to a hose, you’ll need a cage, clamps, and hose clamp pliers.

Dash Size | ||||||

|---|---|---|---|---|---|---|

| For Hose ID | For Hose | Fitting | For Tube OD, mm | Includes | Each | |

Aluminum | ||||||

| 5/8" | 12 | 12 | 18 | 3 Nipple O-Rings, 3 Silver Braze Rings | 0000000 | 000000 |

Jaw | |||||||

|---|---|---|---|---|---|---|---|

| Overall Lg. | Grip Style | Opening Style | Texture | Material | Tip Type | Each | |

Pinch Clamp Pliers—Straight Jaw | |||||||

| 6 7/8" | Cushion | Spring Assisted | Smooth | Steel | Fixed | 0000000 | 0000000 |

Band | |||||||

|---|---|---|---|---|---|---|---|

| For Hose ID | Dash Size | Wd. | Thick. | Reusable | Includes | Each | |

304 Stainless Steel Clamps with 301 Stainless Steel Cage | |||||||

Single Pinch | |||||||

| 5/8" | 12 | 5/16" | 0.024" | No | 2 Clamps, Cage | 0000000 | 00000 |

Band | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | For OD | Dash Size | Wd. | Thick. | Reusable | Number of Pieces | Includes | Each | |

304 Stainless Steel Clamps with 301 Stainless Steel Cages | |||||||||

Single Pinch | |||||||||

| 5/16" to 5/8" | 0.6" to 0.99" | 06, 08, 10, 12 | 5/16" | 0.024" | No | 122 | Cages with 5/16" band width for 5/16" hose ID (10 each) Clamps with 5/16" band width, .32" clamp ID (20 each) Cages with 5/16" band width for 13/32" hose ID (10 each) Clamps with 5/16" band width, .42" clamp ID (20 each) Cages with 5/16" band width for 1/2" hose ID (10 each) Clamps with 5/16" band width, .52" clamp ID (20 each) Cages with 5/16" band width for 5/8" hose ID (10 each) Clamps with 5/16" band width, .62" clamp ID (20 each) Pinch Clamp Pliers Hose Cutter | 0000000 | 0000000 |