About Nuts, Materials, and Finishes

More

How to Install Key-Locking Inserts

More

Black-Phosphate Steel Easy-to-Install Thread-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Also known as E-Z Lok, these inserts use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. Installation requires a drill bit and a standard tap. Then set the insert with a bolt and two nuts, or use an installation bit.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

To drive slotted inserts, you can use a slotted screwdriver instead of using an installation bit or a bolt and two nuts.

For technical drawings and 3-D models, click on a part number.

Easy-to-Install Thread-Locking Insert Assortments

These assortments include various sizes of thread-locking inserts. Also known as E-Z Lok, they use Loctite® adhesive to keep them in place. The adhesive reaches full strength after 72 hours. All inserts have thick walls for strength and can be used to fill a large hole.

Black-phosphate steel inserts are mildly corrosion resistant.

For technical drawings and 3-D models, click on a part number.

For Tap | |||||||

|---|---|---|---|---|---|---|---|

| Includes | No. of Inserts Included | Thread Size | Drill Bit Size | For Max. Hole Dia. | Drive Style | Each | |

Inch Assortments | |||||||

Black-Phosphate Steel | |||||||

| 1/2"-20 Thread × 0.656" Installed Lg. (6 Each) 5/8"-18 Thread × 0.688" Installed Lg. (7 Each) 3/4"-16 Thread × 0.781" Installed Lg. (7 Each) 1"-14 Thread × 1 1/4" Installed Lg. (2 Each) | 22 | 3/4"-10 7/8"-9 1"-8 1 3/8"-12 | 21/32" 49/64" 7/8" 1 9/32" | 21/32" 49/64" 7/8" 1 9/32" | Slotted | 000000000 | 000000 |

For fast installation, use these installation bits with power drills and drill presses.

Black-Phosphate Steel Key-Locking Inserts

A black-phosphate finish provides mild corrosion resistance. Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. Use them to repair or change threads in soft metals such as aluminum. They’re comparable to Keensert® inserts. Installation requires a drill bit, a standard tap, an installation tool, and a hammer.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole with stripped threads.

For technical drawings and 3-D models, click on a part number.

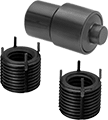

Key-Locking Inserts with Installation Tool

Drive the keys into the surrounding material for a more secure hold than thread-locking inserts. These inserts are used to repair or convert threads in soft metals such as aluminum. They’re comparable to Keensert® inserts.

Black-phosphate steel inserts are mildly corrosion resistant.

Choose inserts with a thick wall for greater strength than thin-wall inserts, or to fill a large hole.

For technical drawings and 3-D models, click on a part number.

| Thread Size | For Tap Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Locking Keys | No. of Inserts Included | Each | |

Black-Phosphate Steel with Thick Wall | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1"-14 | 1 3/8"-12 | 1 3/8" | 1 5/16" | 1 5/16" | 4 | 2 | 000000000 | 000000 |

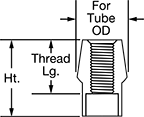

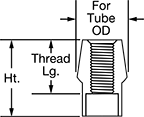

Tube-End Weld Nuts

Weld these nuts to round uncoated metal tubes to attach threaded parts, such as rod ends. Also known as tube adapters and weldable threaded tube ends.

For technical drawings and 3-D models, click on a part number.

Left-Hand Threaded Tube-End Weld Nuts

Use these tube-end nuts with left-hand threaded fasteners. You can weld them to round uncoated metal tubes to attach threaded parts, such as rod ends. Also known as tube adapters and weldable threaded tube ends.

For technical drawings and 3-D models, click on a part number.

Threaded Adapters for Pullers

Use adapters on the ends of forcing screws and face-grip puller legs when pulling shafts, bearing caps, and pinions.

For technical drawings and 3-D models, click on a part number.

| Thread Size | Gender | Each | |

| 5/8"-18 × 1"-14 | Male × Female | 000000 | 000000 |

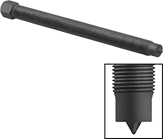

Forcing Screws for Pullers

Make your old puller work like new by replacing worn forcing screws.

| Thread Size | Lg. | Material | Head Style | Each | |

| 1"-14 | 13 3/4" | Steel | Hex | 0000000 | 0000000 |

Ridgid Dies for Cutting Screw Threads

Use these dies with Ridgid pipe and conduit threader die heads on Ridgid pipe and conduit threaders.

| For Thread Size | For Pipe Threader Model Number | Number of Pieces | Material | Each | |

For UNF Right-Hand Thread | |||||

|---|---|---|---|---|---|

For Die Head Models 504A, 711, 811A, 815A, 816, 817 | |||||

| 1"-14 | 300, 535A | 4 | High-Speed Steel | 0000000 | 0000000 |