Filter by

For Use With

Mixer Speed

Mount Type

For Use On

Shaft Material

Motor Type

Electrical Connection

Export Control Classification Number (ECCN)

DFARS Specialty Metals

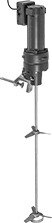

Variable-Speed Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Mount Type | Cord Lg., ft. | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 3.5 amp | 60 | 51" | 50 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 3.5 amp | 60 | 63" | 51 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 90 to 1,750 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 4.5 amp | 60 | 63" | 45 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 90 to 1,750 | 1 | 5 3/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp | 60 | 63" | 55 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 20 to 350 | 1 | 10" | 316 Stainless Steel | 36" | 3/4" | 3.5 amp | 60 | 53 5/8" | 63 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 20 to 350 | 1 | 10" | 316 Stainless Steel | 48" | 3/4" | 3.5 amp | 60 | 65 5/8" | 65 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 20 to 350 | 1 | 11 13/16" | 316 Stainless Steel | 60" | 3/4" | 6 amp | 60 | 77 5/8" | 64 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 20 to 350 | 2 | 8 13/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp | 60 | 65 5/8" | 61 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stand-Mount Electric Mixers for Small Batches

Mixers | Replacement Mixer Propellers | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Features | Includes | Cord Lg., ft. | Motor Enclosure Type | Each | Each | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 0.5 amp | 60 | 20 1/4" | 6 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 0000000 | ——— | 0 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 18" | 3/8" | 5 | 0.5 amp | 60 | 26 1/4" | 7 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 000000 | ——— | 0 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 24" | 3/8" | 5 | 0.5 amp | 60 | 32 1/4" | 8 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 000000 | ——— | 0 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 30" | 3/8" | 5 | 0.5 amp | 60 | 38 1/4" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 000000 | ——— | 0 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/15 | 40 to 2,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 1.1 amp | 60 | 21" | 8 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 00000000 | 000000 | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/10 | 5 to 1,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 26 | 0.8 amp | 60 | 25" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 00000000 | 00000000 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/10 | 300 to 6,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 0.8 amp | 60 | 21" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 000000000 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 40 to 1,200 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 26 | 0.8 amp | 60 | 23" | 12 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/15 | 10 to 350 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 13 | 1.1 amp | 60 | 24" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stand Mixers

No. of Speeds | Max. Mixer Speed, rpm | Current, amp | Freq., Hz | Ht. | Wd. | Dp. | Housing Material | Container Material | Food Industry Std. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC Single Phase—3-Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7 qt. Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | 900 | 4.2 | 60 | 17 3/4" | 9 1/4" | 16 1/4" | Aluminum | 303 Stainless Steel | NSF/ANSI 8 | Aluminum Mixing Paddle, Stainless Steel Mixing Paddle, Splash Guard with Feed Chute | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tabletop Blenders

Blenders | Repair Kits | Replacement Containers with Lid | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Speeds | Max. Mixer Speed, rpm | Current, amp | Freq., Hz | Ht. | Wd. | Dp. | Housing Material | Container Material | Each | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3-Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 L Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 22,000 | 3.6 | 60 | 16 1/2" | 8" | 7" | Zinc Alloy | 304 Stainless Steel | 00000000 | 0000000 | Blade Assembly, Drive Coupling Assembly | 0000000 | 000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

64 fl. oz. Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 24,000 | 13 | 60 | 17 3/4" | 7 1/2" | 8" | Polycarbonate | 304 Stainless Steel | 00000000 | 000000 | — | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

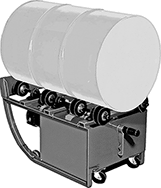

Hazardous Location No-Mess Drum Mixers

Power, hp | Mixer Speed, rpm | Wt. Cap., lb. | Current | Freq., Hz | Ht. | Wd. | Dp. | Wt., lb. | Hazardous Location Rating | Features | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC/240V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 15 to 24 | 300 | 7.4 amp/3.7 amp | 60 | 20" | 35" | 21" | 183 | NEC Class I Divisions 1, 2 Group D NEC Class II Divisions 1, 2 Groups F, G | Adjustment Dial | Chain and Guard Grounding Strap Two 3" Dia. Casters | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Immersion Blenders

No. of Speeds | Max. Mixer Speed, rpm | Shaft Lg. | Current, amp | Freq., Hz | Dia. | Lg. | Housing Material | Body Material | Shaft Material | Food Industry Std. | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC Single Phase—3 Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

37 L Capacity | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 18,000 | 12" | 9.54 | 60 | 5.5" | 27" | Polycarbonate | Plastic | Stainless Steel | NSF/ANSI 8 | UL Listed | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Mess Drum Mixers

Power, hp | Mixer Speed, rpm | Wt. Cap., lb. | Current | Freq., Hz | Ht. | Wd. | Dp. | Wt., lb. | Cord Lg., ft. | Features | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

120V AC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Phase—Three-Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 15 to 24 | 300 | 7.4 amp | 60 | 20" | 35" | 21" | 175 | 3 | Adjustment Dial | Chain and Guard Grounding Strap Two 3" Dia. Casters | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||