How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

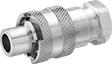

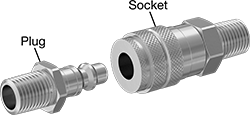

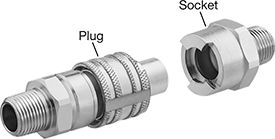

Industrial Quick-Disconnect Hose Couplings for Air

A complete coupling consists of a plug and a socket (both sold separately or in a set) that connect and disconnect quickly. Use them if you need frequent access to a line. They are also known as industrial interchange couplings. All Industrial plugs are compatible with any of the Industrial sockets of the same coupling size, regardless of the pipe size or barbed hose ID.

Brass is softer than other metals, so it’s easier to thread together. It has good corrosion resistance. 303 stainless steel has very good corrosion resistance, so it’s the best choice for high-humidity environments.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Attachment Type: See table

- Specifications Met: See table

Plugs are also known as nipples.

Plugs and sockets with a clamp-on/crimp-on barbed end insert into rubber hose and secure with a clamp or a crimp-on hose ferrule.

Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | For Hose ID | Attachment Type | Specifications Met | Each | |

Brass | |||||||

| 1/2 | 3/8" | 9/16" | 3/4" | Band-and-Buckle Clamp | Fed. Spec. A-A-59439, ISO 6150/B | 0000000 | 000000 |

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -40° to 225° F

- Attachment Type: See table

- Specifications Met: See table

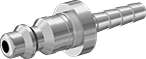

Sockets have a shut-off valve that stops the flow when the coupling is separated, so air won’t leak from the line.

Plugs and sockets with a clamp-on/crimp-on barbed end insert into rubber hose and secure with a clamp or a crimp-on hose ferrule.

Push-to-connect sockets join by forcefully pushing the plug and socket together until you hear a click. Unlike sleeve-lock sockets, you should not slide back the sleeve to connect. To disconnect, slide the sleeve on the socket forward until the plug ejects.

For Plug Tip | |||||||

|---|---|---|---|---|---|---|---|

| Coupling Size | Lg. | Dia. | For Hose ID | Attachment Type | Specifications Met | Each | |

Brass | |||||||

| 1/4 | 3/16" | 5/16" | 1/4" | Crimp-On Hose Ferrule | Fed. Spec. A-A-59439, ISO 6150/B | 0000000 | 000000 |

| 1/4 | 3/16" | 5/16" | 3/8" | Crimp-On Hose Ferrule | Fed. Spec. A-A-59439, ISO 6150/B | 0000000 | 00000 |

303 Stainless Steel | |||||||

| 1/4 | 3/16" | 5/16" | 1/4" | Crimp-On Hose Ferrule | Fed. Spec. A-A-59439, ISO 6150/B | 0000000 | 00000 |

| 1/4 | 3/16" | 5/16" | 3/8" | Crimp-On Hose Ferrule | Fed. Spec. A-A-59439, ISO 6150/B | 0000000 | 00000 |

Grip-Lock Hose Couplings for Air

Also known as Bowes couplings, these consist of a plug and a socket (both sold separately) that connect with a quarter twist. They can handle higher-pressures than twist-claw couplings, and have a lower profile to fit in cramped spaces. All of the grip-lock plugs are compatible with any of the grip-lock sockets, regardless of the pipe size or barbed hose ID.

Plugs have a spring-loaded locking sleeve to prevent accidental disconnection. The sleeve automatically locks into place when you connect the coupling. To disconnect, slide the locking sleeve back and twist the coupling apart.

Brass plugs and sockets are softer than other metal plugs and sockets, so they’re easier to thread together. They have good corrosion resistance. NPTF (Dryseal) threads are compatible with NPT threads.

Warning: There is no valve in these couplings. Stop the flow of air before you disconnect the line.

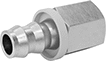

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance, so they’re the best choice for high-humidity environments.

Fittings that swivel until tightened rotate 360° for easy installation.

Fittings with a threaded end are also known as hose nipples.The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

NPTF (Dryseal) threads are compatible with NPT threads.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

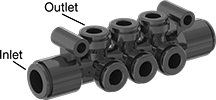

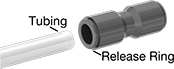

Push-to-Connect Tube Fittings for Air

- Temperature Range: 0° to 170° F, except polybutylene plastic fittings are 32° to 140° F

- Tubing: Use with firm (Durometer 95A-45D) polyethylene plastic or polyurethane rubber

- Specifications Met: ISO 14743, except cartridges and polybutylene plastic fittings

Insert tubing into these fittings and an internal gripping ring and O-ring hold the tubing tight. They are also known as instant fittings. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings have good corrosion resistance. Use them in low-pressure applications.

Identification rings (sold separately) snap over the release ring so you can color-code your lines.

Clips (sold separately) align and organize your tubing and fittings.

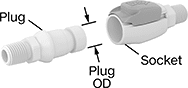

High-Flow Quick-Disconnect Tube Couplings for Air and Water

- Temperature Range: Acetal Plastic: 32° to 180° F

Polypropylene Plastic: 32° to 160° F - Tubing: Use with soft or firm (Durometer 55A-95A) nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PVC plastic or TPE plastic

- Specifications Met: Acetal Plastic: FDA Compliant 21 CFR 177.2470

Polypropylene Plastic: FDA Compliant 21 CFR 177.1520

A spring-free flow path allows more air or water to pass through these tube couplings at lower line pressures than other quick-disconnect couplings. This reduces turbulence, foaming, bubbles, and blockage. They have a shut-off valve that stops the flow when the coupling is disconnected, so air or water won’t leak from your line. Unlike couplings with a button release, these have a safety slide to reduce accidental separation from bumps or drops. They’re often used in laboratories, pharmaceutical facilities, and other sterile environments. All are FDA compliant for direct contact with food.

When you insert the plug into the socket, it’ll connect with a click. To disconnect, slide the latch on the socket and remove the plug.

Acetal plugs and sockets are stronger and harder than polypropylene plugs and sockets, making them less likely to scratch. Their slippery surface also makes them more wear resistant. They resist moisture, so they won't crack or become brittle when used in humid environments.

Polypropylene plugs and sockets are flexible yet tough, so they keep their shape and strength after repeated use. They are more water resistant than acetal plugs and sockets and can be completely submerged.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

They have a single barb that grips onto tubing or hose and provides a smooth clamping surface for extra-tight connections that minimize leaks.

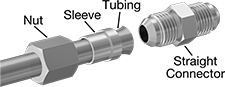

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

- For Use With: See table

- Temperature Range: See table

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/2" | 1 1/2 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 1 1/2" | 316 Stainless Steel | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 1 1/2" | 316 Stainless Steel | 000000000 | 000000 |

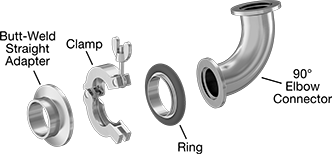

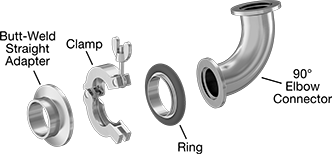

Quick-Clamp High-Vacuum Fittings for Stainless Steel Tubing

- For Use With:

Fittings with Gasket End: Air, Argon, Helium, Nitrogen

All Other Fittings: Air - Specifications Met: ISO 2861

Instead of a gasket, these fittings have a metal-reinforced O-ring that is designed for high-vacuum applications, such as vacuum coating and heat treating, leak testing, and analyzing gases. Also known as KF, QF, and NW fittings, they are the most common type of connection in high-vacuum systems. Connect with a clamp and another quick-clamp fitting for fast, easy access to your line. To use fittings in pressure applications, use a pressure-rated ring (sold separately). Made of 304 stainless steel, these fittings have very good corrosion resistance.

Note: To complete a connection, you’ll need two quick-clamp fittings, a ring, and a clamp (all sold separately).

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with flanged end connect to pumps, valves or gauges that have flanged connections. Also known as conflat, CF, or UHV fittings, they have a higher vacuum rating than quick-clamp fittings, so these adapters allow you to connect between different levels of vacuum within a system. A copper gasket (sold separately) creates a tight seal between the two flanges.

Quick-Clamp Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | For Bolt Dia. | Bolts Included | Max. Vacuum | Max. Pressure | Each | |

| 1 1/2" | 2.16" | 40 | ISO-KF | 2 1/2" | 4 1/2" | 63 | CF | 3 5/8" | 21/64" | 8 | 5/16" | No | 10 -8 torr @ 72° F | 5 psi @ 72° F | 00000000 | 0000000 |

| Copper Gasket for 4 1/2" Flange OD (Flanged End) | 0000000 | Each | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Fittings with compression end bite into hard metal and plastic tubing in low-to-medium-pressure applications. Also known as flareless fittings.

| For Tube OD (Flanged) | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | For Tube OD (Compression) | For Tube Wall Thick. | Material | Max. Vacuum | Each | |

| 1 1/2" | 2.16" | 40 | ISO-KF | 1 1/8" | 0.065" | 304 Stainless Steel | 10 -8 torr @ 72° F | 00000000 | 0000000 |

| 2" | 2.95" | 50 | ISO-KF | 1 1/8" | 0.065" | 304 Stainless Steel | 10 -8 torr @ 72° F | 00000000 | 000000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Clamps tighten by hand.

Lever clamps are also known as toggle clamps.

Clamps with lanyard let you secure the clamp to equipment.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Lanyard Lg. | Each | |

Wing Nut | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | __ | 0000000 | 00000 |

Lever with Lanyard | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 5 3/4" | 00000000 | 00000 |

- Temperature Range:

Fittings with Viton® Fluoroelastomer Rubber O-Ring: 0° to 300° F

Fittings with Silicone Rubber O-Ring: -50° to 390°F - Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by an O-ring.

Silicone rings withstand higher temperatures than fluoroelastomer ones.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Inner Ring Material | Max. Vacuum | Max. Pressure | Each | |

Viton® Fluoroelastomer Rubber O-Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

Rings | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 0000000 | 00000 |

Rings with Stainless Steel Screen | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 75 psi @ 72° F | 0000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 50 psi @ 72° F | 0000000 | 00000 |

Silicone Rubber O-Ring | ||||||||

Rings | ||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | Not Rated | 00000000 | 00000 |

- Temperature Range: 0° to 300° F

- Tubing: Use with 304/304L stainless steel, 316/316L stainless steel, or aluminum

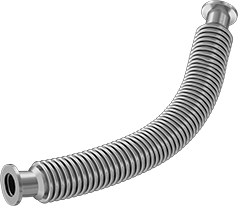

Hose absorbs moderate vibration

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Bend Radius | Flexibility | Each | |

4 3/16" Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 0000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | __ | Flexible | 0000000 | 000000 |

12" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

24" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

39" Lg. | |||||||||

| 1 1/2" | 2.16" | 40 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 2 1/2" | Flexible | 00000000 | 000000 |

| 2" | 2.95" | 50 | ISO-KF | 304 Stainless Steel | 10 -8 torr @ 72° F | 3 1/4" | Flexible | 00000000 | 000000 |

- Temperature Range: 0° to 190° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Valves are also known as vacuum isolation valves. They connect to a vacuum system so you can install gauges, release gases, and remove air. They operate manually and have a compact body that fits easily into tight spaces.

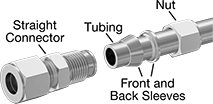

Yor-Lok Fittings for Stainless Steel Tubing

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | For Hole Dia. | For Max. Wall Thick. | Each | |

NPT Threads | |||||||||

| 3/4" | 0.049" to 0.109" | 3/4 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 1 1/16" | 25/32" | 00000000 | 0000000 |

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

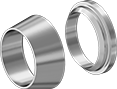

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 3/4" | 0.049" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,900 psi @ 72° F | 0000000 | 0000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 000000 |