How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Nickel-Plated Brass Push-to-Connect Tube Fittings for Air

(SAE Straight) Male

Threads with Gasket

- For Use With: Air, Lubricated Air

- Temperature Range: 0° to 140° F

- Tubing: Fittings with Release Ring and Fittings with no Release Type: Use with firm or hard (Durometer 95A-60D) nylon plastic, polyethylene plastic or polyurethane rubber

Fittings with Release Sleeve: Use with firm or hard (Durometer 95A-60D) polyethylene plastic or polyurethane rubber

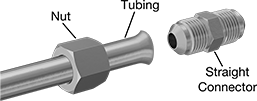

Made of nickel-plated brass, these fittings have better corrosion resistance than unplated brass fittings. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring or sleeve and pull the tubing out of the fitting.

Fittings with release sleeve are easier to disconnect than fittings with a release ring because they are seamless and won't collect dirt and debris.

Metric and UN/UNF (SAE Straight) male threads with gasket or thread sealant provide extra protection against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

Release Sleeve | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Each | |

Metric Threads | |||||||

| 3/16" | M3 | 0.5 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 000000 |

| 3/16" | M5 | 0.8 | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

UN/UNF (SAE Straight) Threads | |||||||

| 5/32" | 10-32 | __ | Nickel-Plated Brass | Buna-N Rubber | 230 psi @ 72° F | 00000000 | 00000 |

Moisture-Resistant Push-to-Connect Tube Fittings for Air and Water

These fittings won’t absorb moisture, so they’re good for water and high-humidity air applications. Also known as instant fittings, they connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. They have good corrosion resistance.

Nickel-plated brass fittings have better corrosion resistance than unfinished brass fittings.

Fittings with thread sealant offer extra protection against leaks.

UN/UNF (SAE Straight) male threads have a gasket or a washer and gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- For Use With: Air, Lubricated Air, Water

- Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

Release Ring | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Color | Max. Pressure | Features | Choose a Material | Each | |

NPT Threads | ||||||||

| 5/32" | 1/16 | Plastic | Orange | 140 psi @ 72° F | Acrylic Thread Sealant | 00000000 | 00000 | |

- For Use With: Air, Lubricated Air, Water

- Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

Release Ring | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Pipe Size | Material | Color | Max. Pressure | Drive Size | Features | Choose a Material | Each | |

NPT Threads | |||||||||

| 5/32" | 1/16 | Plastic | Orange | 140 psi @ 72° F | 1/8" | Acrylic Thread Sealant | 00000000 | 00000 | |

| 3/16" | 1/8 | Plastic | Orange | 140 psi @ 72° F | 1/8" | Acrylic Thread Sealant | 00000000 | 0000 | |

| 1/4" | 1/8 | Plastic | Orange | 140 psi @ 72° F | 3/16" | Acrylic Thread Sealant | 00000000 | 0000 | |

| 1/4" | 1/4 | Plastic | Orange | 140 psi @ 72° F | 3/16" | Acrylic Thread Sealant | 00000000 | 0000 | |

- For Use With: Air, Lubricated Air, Water

- Temperature Range: 32° to 100° F

- Tubing: Use with firm (Durometer 90A-95A) nylon plastic or polyurethane rubber

Release Ring | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Material | Color | Max. Pressure | Choose a Material | Each | |

UN/UNF (SAE Straight) Threads | |||||||

| 1/8" | 10-32 | Plastic | Orange | 140 psi @ 72° F | 00000000 | 00000 | |

Brass Low-Pressure Barbed Tube Fittings for Air and Water

Made of brass, these fittings resist corrosion from water and are more durable than plastic and aluminum fittings. Use them for low-pressure HVAC systems, drain lines, and other fluid transfer applications, as well as air lines where water vapor and condensate form. The barbs tightly grip tubing for a secure hold. For the best grip, make sure your tubing is squarely cut.

UN/UNF (SAE Straight) male threads with gasket provide extra protection against leaks. Also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

- Temperature Range: See table

- Tubing: See table

For Tube | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Thread Size | Number of Barbs | Straight Body Shape | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Lg. | Material | Hardness Rating | Hardness | Pkg. Qty. | Pkg. | |

UN/UNF (SAE Straight) Threads | ||||||||||||||

| 1/8" | 5/16"-18 | Single | Hex | Brass | Buna-N Rubber | 125 psi @ 72° F | -40° to 500° | 25/32" | Polyurethane Rubber | Firm | Durometer 85A | 1 | 00000000 | 000000 |

| 1/4" | 10-32 | Single | Hex | Brass | Buna-N Rubber | 125 psi @ 72° F | -40° to 500° | 25/32" | Polyurethane Rubber | Firm | Durometer 85A | 1 | 00000000 | 0000 |

- Temperature Range: See table

- Tubing: See table

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through your wall or panel to create an inlet or outlet.

For Tube | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Number of Barbs | Straight Body Shape | Material | Max. Pressure | Temp. Range, °F | Lg. | For Hole Dia. | For Max. Wall Thick. | Material | Hardness Rating | Hardness | Each | |

| 1/16" | Single | Hex | Brass | 125 psi @ 72° F | -40° to 500° | 25/32" | 3/16" | 1/4" | Polyurethane Rubber | Firm | Durometer 85A | 00000000 | 00000 |

| 3/32" | Single | Hex | Brass | 125 psi @ 72° F | -40° to 500° | 25/32" | 3/16" | 1/4" | Polyurethane Rubber | Firm | Durometer 85A | 00000000 | 0000 |

| ID | OD | Gasket Material | Max. Pressure | Gasket Color | Pkg. Qty. | Pkg. | |

| 5/32" | 15/64" | Buna-N Rubber | 150 psi @ 72° F | Black | 25 | 0000000 | 00000 |

Choose-a-Color Aluminum Low-Pressure Barbed Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water

- Temperature Range: -40° to 230° F

- Tubing: Use with hard (Durometer 75A-60D) EVA plastic, polyethylene plastic, polyurethane rubber or PVDF plastic

Color-code fittings for easy identification. Fittings are aluminum, which is lightweight with good corrosion resistance. The barb grips onto tubing, providing a secure hold with no clamp required.

Metric and UN/UNF (SAE Straight) male threads have a gasket for a tight seal.

(SAE Straight) Male

Threads with Gasket

Aluminum Low-Pressure Barbed Tube Fittings for Air and Water

- For Use With: Air, Lubricated Air, Water

- Temperature Range: -40° to 230° F

- Tubing: Use with hard (Durometer 75A-60D) EVA plastic, polyethylene plastic, polyurethane rubber or PVDF plastic

Made of aluminum, these fittings are lighter in weight than other metal barbed tube fittings and have good corrosion resistance. The barb grips onto tubing, providing a secure hold with no clamp required.

Metric, BSPP, and UN/UNF (SAE Straight) male threads have a gasket or O-ring for a tight seal.

(SAE Straight) Male

Threads with Gasket

| For Tube ID | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Each | |

Metric Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8" | M8 | 1 | Aluminum | Fiber | 125 psi @ 72° F | 00000000 | 00000 |

| 0.17" | M8 | 1 | Aluminum | Fiber | 125 psi @ 72° F | 00000000 | 0000 |

| 1/4" | M5 | 0.8 | Aluminum | Fiber | 125 psi @ 72° F | 00000000 | 0000 |

| 1/4" | M6 | 1 | Aluminum | Fiber | 125 psi @ 72° F | 00000000 | 0000 |

| 4mm | M8 | 1 | Aluminum | Fiber | 125 psi @ 72° F | 00000000 | 0000 |

Stainless Steel High-Pressure Barbed Tube Fittings for Air and Water

- Temperature Range: See table

- Tubing: Use with firm (Durometer 75A-95A) EVA plastic, polyethylene plastic, polypropylene plastic or PVC plastic

Fittings withstand pressures up to 250 psi. They are 303 stainless steel for very good corrosion resistance.

Metric, BSPP, and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

UN/UNF (SAE Straight)

Male Threads with Gasket

| For Tube ID | Thread Size | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Number of Barbs | Each | |

UN/UNF (SAE Straight) Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4" | 10-32 | 303 Stainless Steel | Viton® Fluoroelastomer Rubber | 250 psi @ 72° F | -40° to 1200° F | Single | 0000000 | 00000 |

Tight-Seal Plastic Barbed Tube Fittings for Air and Water

Minimize leaks in your line—these fittings have a single barb that creates a smooth clamping surface for extra-tight connections. Fittings are nylon for excellent impact and abrasion resistance.

- Temperature Range: See table

- Tubing: Use with firm (Durometer 75A-80A) polyurethane rubber or PVC plastic

- Clarity: Black: Opaque; White: Opaque; Off-White: Semi-Clear

| For Tube ID | Thread Size | Material | Max. Pressure | Temp. Range, °F | Pkg. Qty. | Color | Pkg. | |

UNF Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8" | 1/4"-28 | Nylon Plastic | Not Rated | -50° to 275° | 10 | White | 00000000 | 00000 |

Tight-Seal Moisture-Resistant Plastic Barbed Tube Fittings for Air and Water

- Temperature Range: -20° to 280° F

- Tubing: Use with firm or soft (Durometer 50A-90A) polyurethane rubber or PVC plastic

- Specifications Met: FDA Compliant 21 CFR 177.2470

Fittings have a single barb that creates a smooth clamping surface for extra-tight connections that minimize leaks. Made of acetal, they won’t absorb water and lose strength, even in high-humidity environments.

| For Tube ID | Thread Size | Material | Color | Clarity | Max. Pressure | Each | |

UNF Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8" | 1/4"-28 | Acetal Plastic | White | Semi-Clear | Not Rated | 00000000 | 00000 |

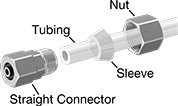

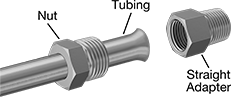

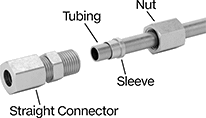

Tight-Seal Brass Compression Tube Fittings for Air and Water

- Temperature Range: -65° to 250° F

- Tubing: Use with firm (Durometer 95A) EVA plastic or polyurethane rubber

- Specifications Met: SAE J512

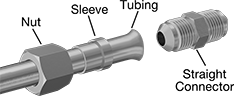

A built-in tube support slips inside the tubing to prevent collapsing and provides a sturdy connection for an extra-tight seal. Fittings have a single sleeve (ferrule) that compresses the tubing as you tighten the nut. The nut and sleeve are included. Fittings are also known as flareless fittings. They are brass for good corrosion resistance.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 3/8" | 1/8 | Brass | 90 psi @ 72° F | 00000000 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/8" | Brass | 90 psi @ 72° F | 25 | 00000000 | 000000 |

Sleeve | ||||||

|---|---|---|---|---|---|---|

| For Tube OD | Material | Color | Max. Pressure | Pkg. Qty. | Pkg. | |

| 3/8" | Acetal Plastic | White | 90 psi @ 72° F | 25 | 00000000 | 00000 |

Plastic Luer Lock Tube Couplings for Air and Water

- For Use With: Nylon Plastic: Air, Water

Polycarbonate Plastic: Air

Polypropylene Plastic: Water - Temperature Range: See table

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

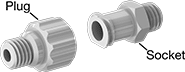

Made of plastic, these couplings are lighter in weight than metal luer lock couplings. They're a popular choice in labs because of their versatility—they fit any other luer lock plug, socket, syringe, or needle. Quick to attach and detach, they’re often used in lines that are frequently disconnected. They have a compact body for easy installation in tight spaces. Use them in low-pressure applications. These couplings are open-flow style, so there is no shut-off valve to stop the flow when they’re separated.

Nylon couplings have excellent impact and abrasion resistance. They’re for general purpose applications.

Plugs with a locking ring are more secure than those without a locking ring. Give the ring a half turn to lock these couplings in place. You can’t remove the locking ring.

Note: For a complete coupling, order a plug and a socket.

Barbed plugs and sockets insert into tubing and secure with a clamp.

| For Tube ID | Color | Clarity | Max. Pressure | Temp. Range, °F | Locking Ring Included | Pkg. Qty. | Pkg. | |

Nylon Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8" | Red | Opaque | Not Rated | Not Rated | With Locking Ring | 10 | 000000000 | 00000 |

| 1/8" | White | Opaque | 40 psi @ 72° F | -20° to 200° F | With Locking Ring | 10 | 000000000 | 0000 |

Polycarbonate Plastic | ||||||||

| 1/8" | Clear | Clear | 40 psi @ 72° F | -20° to 200° F | With Locking Ring | 10 | 000000000 | 0000 |

| Pipe Size | Color | Clarity | Max. Pressure | Temp. Range, °F | Pkg. Qty. | Pkg. | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

Nylon Plastic | |||||||

| 1/8 | White | Opaque | 40 psi @ 72° F | -20° to 200° F | 10 | 000000000 | 000000 |

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

| For Tube OD | Max. Pressure | Max. Vacuum | Temp. Range Min., °F | Temp. Range Max., °F | Wall Thick. | For Use With | Each | |

304/304L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

Polished | ||||||||

| 2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 0.065" | Air, Food, Water | 00000000 | 000000 |

316/316L Stainless Steel | ||||||||

Polished | ||||||||

| 2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 0.065" | Air, Food, Water | 0000000 | 00000 |

Dull | ||||||||

| 2" | 550 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 0.065" | Air, Food, Water | 00000000 | 00000 |

Flanged Ultra-High-Vacuum Fittings for Stainless Steel Tubing

- For Use With: Air

- Temperature Range:

Flanges: -300° to 800° F

Gaskets: Not Rated - Tubing: Use with 304/304L and 316/316L stainless steel

- Specifications Met:

Flanges: ASTM A240, ASTM E45, ASTM E12

Gaskets: ASTM B152-179, ASTM F68

Create access points in ultra-high-vacuum lines or chambers by bolting two same-size flanges together with a copper gasket (sold separately) between them. The flanges’ sharp edges dig into the copper gasket and form an extremely tight seal, which means they handle higher vacuum pressures than other high-vacuum fittings with rubber gaskets. Also known as CF, Conflat, and UHV fittings, use them in vacuum coating, heat treating, and drying applications, as well as for leak testing and analyzing gases. They’re stainless steel so they resist rusting.

Fittings with a rotating flange turn so you can easily match up the bolt holes with another flange that may be misaligned.

Socket-connect flanges are easier to weld than butt-weld flanges because they don’t need to align perfectly to tubing; insert the tubing into the socket end and weld together.

Caps are also known as blind flanges.

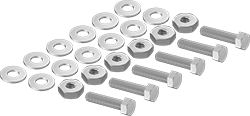

Bolt kits are required to make a complete connection.

Socket-Connect Tube Connection | Flanged Tube Connection | Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Socket Dp. | For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||||

| 4" | 7/16" | 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 2 | 25/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

Rotating | ||||||||||||||||

| 4" | 7/16" | 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 2 | 25/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 000000 |

Bolt Holes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Bolts Included | No. of Bolt Kits Required | Lg. | Max. Vacuum | Material | Appearance | Each | |

Fixed | ||||||||||||||

| 4" | 6" | 100 | CF | 5 1/8" | 21/64" | 16 | No | 2 | 25/32" | 10 -13 torr @ 72° F | 304 Stainless Steel | Polished | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Gasket Material | Specifications Met | Each | |

| 4" | 6" | Copper | ASTM F68 | 0000000 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | Bolt Dia. | Thread Size | No. of Bolts Included | No. of Nuts Included | No. of Washers Included | Bolt Material | Each | |

| 6" | 100 | 5/16" | 5/16"-24 | 16 | 16 | 32 | 18-8 Stainless Steel | 0000000 | 000000 |

Supported 45° Flared Fittings for Copper and Brass Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper

- Specifications Met:

Metric: SAE J512, SAE J513, UL Listed

All other fittings: SAE J512, UL Listed; except tee connectors for 1/2" tube OD

The flared end nests inside the fitting body, providing extra support to the tubing. Fittings are also known as inverted 45° flared fittings, refrigeration fittings, and SAE fittings. To assemble, place the nut (sold separately) on the tubing, flare the end of the tubing, then insert the tubing into the fitting and tighten the nut. Fittings are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

| 5/16" | 0.032" | Brass | 1,200 psi @ 72° F | 000000000 | 00000 | 00000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

30° Flared Fittings for Steel Tubing

- Specifications Met: See table

Also known as JIS (Japanese Industrial Standard) fittings, these have a 30° flare on one or both ends. Fittings are zinc-plated steel for fair corrosion resistance.

- Temperature Range: -65° to 500° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Specifications Met | Each | |

| 1/4" | 1/8 | Zinc-Plated Steel | 5,000 psi @ 72° F | ISO 228-1, JIS B 0202, JIS B 8363 | 00000000 | 000000 |

Compression Fittings for Steel Tubing

- For Use With: Inch: Air, Hydraulic Fluid, Water

Metric: Hydraulic Fluid - Tubing: Inch: Use with welded steel

Metric: Use with seamless steel - Specifications Met: Inch: SAE J514

Metric: ISO 8434, DIN 2353

A single sleeve (ferrule) bites into tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless and bite fittings.

Zinc-plated steel fittings have fair corrosion resistance.

- Temperature Range: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |

- Temperature Range: See table

| For Tube OD | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |

- Temperature Range: See table

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 3/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | -65° to 400° | 000000000 | 00000 |