How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Plastic and Rubber Tubing

More

Hard Plastic Tubing for Vehicle Air Systems

- Semi-Flexible

- Compatible with Compression and Push to Connect Tube Fittings

- Hard (Durometer 65D)

- Temperature Range: -40° to 200° F

Safely power seat controls, horns, and other vehicle parts with compressed air. This tubing meets SAE or D.O.T. testing and performance standards for use in air-powered vehicle systems. It’s opaque, so you can’t see what’s flowing through the line. Semi-flexible, it’s good for gradual bends.

Tubing that meets D.O.T. FMVSS 106 is rated for use in motor vehicle brake systems. It’s also known as air brake tubing.

Flame-Retardant Hard Plastic Tubing for Air and Water

This tubing is self-extinguishing to delay the spread of flames to valuable equipment. Tubing is opaque, so you cannot see what’s flowing through the line. It is semi-flexible, so it is good for gradual bends.

Polyethylene tubing can handle a wider temperature range than nylon tubing. It meets UL 94 V-2 for flame retardance and UL 1820 specifications and testing requirements for flame propagation and smoke density. It is designed for use in air control systems.

Tubing with stripe allows you to color-code your lines for easy identification.

Black with

White Stripe

Black with

Green Stripe

with Orange

Stripe

Black with

Purple Stripe

Black with

Yellow Stripe

Black with

Blue Stripe

- Semi-Flexible

- Compatible with Push to Connect Tube Fittings

- Hard

- Temperature Range: -70° to 175° F

- Specifications Met: UL 1820, UL 94 V-2

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Choose a Stripe Color | Lengths, ft. | Per Ft. | |

Black Tubing without Stripe | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/32" | 5/32" | 1/32" | 1/2" | 110 psi @ 72° F | __ | 0000000 | 00000 | |

| 11/64" | 1/4" | 3/64" | 3/4" | 100 psi @ 72° F | __ | 0000000 | 000 | |

| 1/4" | 3/8" | 1/16" | 1 1/2" | 100 psi @ 72° F | __ | 0000000 | 000 | |

| 3/8" | 1/2" | 1/16" | 1 3/4" | 70 psi @ 72° F | __ | 0000000 | 0000 | |

Black Tubing with Stripe | ||||||||

| 3/32" | 5/32" | 1/32" | 1/2" | 110 psi @ 72° F | 00000000 | 000 | ||

| 11/64" | 1/4" | 3/64" | 3/4" | 100 psi @ 72° F | 00000000 | 000 | ||

| 1/4" | 3/8" | 1/16" | 1 1/2" | 100 psi @ 72° F | 00000000 | 000 | ||

| 3/8" | 1/2" | 1/16" | 1 3/4" | 70 psi @ 72° F | 00000000 | 0000 | ||

Crack-Resistant Hard Plastic Tubing for Air and Water

- Semi-Flexible

- Compatible with Compression Tube Fittings

- Hard (Durometer 65D)

Made of resilient polypropylene, this tubing won’t crack due to stress or impact. Tubing is semi-clear, so you get a limited view inside the line. It is semi-flexible, so it is good for gradual bends.

Choose-a-Color Firm Plastic and Rubber Tubing for Air and Water

Multiple colors allow you to color-code your line for easy identification. Tubing is flexible, so it bends easily around objects.

Polyurethane rubber tubing can handle higher pressures than PVC plastic tubing and can also be used in vacuum applications. It is ether based, so it performs better in humid environments than ester-based polyurethane.

Opaque tubing doesn’t allow you to see what’s flowing through the line. Clear tubing allows you to easily monitor flow.

- Flexible

- Compatible with Barbed Tube Fittings and Push to Connect Tube Fittings

- Firm (Durometer 95A)

- Temperature Range: See table

| ID | OD | Wall Thick. | Bend Radius | Temp. Range, °F | For Connection Style | Max. Pressure | Max. Vacuum | Choose a Color | Lengths, ft. | Per Ft. | |

Inch | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 1/8" | 1/32" | 1/4" | -40° to 160° | Barbed, Push to Connect | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 00000 | ||

| 3/32" | 5/32" | 1/32" | 3/8" | -40° to 160° | Barbed, Push to Connect | 210 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 000 | ||

| 5/32" | 1/4" | 3/64" | 1/2" | -40° to 160° | Barbed, Push to Connect | 170 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 000 | ||

Metric | |||||||||||

| 2.4mm | 4mm | 0.8mm | 9mm | -40° to 160° | Barbed, Push to Connect | 210 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000 | ||

| 4mm | 6mm | 1mm | 12mm | -40° to 160° | Barbed, Push to Connect | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000 | ||

- Flexible

- Compatible with Barbed Tube Fittings and Push to Connect Tube Fittings

- Firm (Durometer 95A)

- Temperature Range: See table

| ID | OD | Wall Thick. | Bend Radius | For Connection Style | Temp. Range, °F | Max. Pressure | Max. Vacuum | Choose a Color | Lengths, ft. | Per Ft. | |

Inch | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 1/8" | 1/32" | 1/4" | Barbed, Push to Connect | -40° to 160° | 250 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 00000 | ||

| 3/32" | 5/32" | 1/32" | 3/8" | Barbed, Push to Connect | -40° to 160° | 210 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 000 | ||

| 5/32" | 1/4" | 3/64" | 1/2" | Barbed, Push to Connect | -40° to 160° | 170 psi @ 72° F | 28 in. of Hg @ 72° F | 0000000 | 000 | ||

Metric | |||||||||||

| 2.4mm | 4mm | 0.8mm | 9mm | Barbed, Push to Connect | -40° to 160° | 210 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000 | ||

| 4mm | 6mm | 1mm | 12mm | Barbed, Push to Connect | -40° to 160° | 160 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 000 | ||

| 6.5mm | 10mm | 1.75mm | 22mm | Barbed, Push to Connect | -40° to 160° | 170 psi @ 72° F | 28 in. of Hg @ 72° F | 00000000 | 0000 | ||

Weld-Spatter-Resistant Firm Rubber Tubing for Air and Water

- Semi-Flexible

- Compatible with Push to Connect Tube Fittings

- Hardness:

Inch: Firm (Durometer 95A)

Metric: Firm (Durometer 90A) - Temperature Range:

Inch: -40° to 165° F

Metric: 0° to 140° F

Designed for use in welding applications, this tubing is specially formulated to self-extinguish. It’s made of ether-based polyurethane, so it has excellent resistance to abrasion and tearing and stays strong and durable in humid environments. Tubing is opaque, so you cannot see what is flowing through the line. It is semi-flexible, which is good for gradual bends.

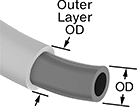

To attach fittings, use a cutting tool (sold separately) to strip away the outer layers of tubing. The tube OD dimension refers to the inner layer of tubing. Attach a protective cover (sold separately) to prevent weld spatter from getting between the tubing and fitting.

Inch tubing has two layers of material. It meets UL 94 V-0 for better flame retardance than metric tubing. It can handle higher pressures and a wider temperature range than metric tubing.

Tubing | Protective Covers | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Outer Layer OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Choose a Color | Lengths, ft. | Per Ft. | Each | ||

Opaque Polyurethane Rubber | ||||||||||||

Inch | ||||||||||||

| 5/32" | 1/4" | 11/32" | 3/64" | 3/4" | 240 psi @ 73° F | 28 in. of Hg @ 72° F | 0000000 | 00000 | 00000000 | 00000 | ||

| 1/4" | 3/8" | 15/32" | 1/16" | 1" | 230 psi @ 73° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | 00000000 | 000 | ||

| 5/16" | 1/2" | 19/32" | 3/32" | 2" | 220 psi @ 73° F | 28 in. of Hg @ 72° F | 0000000 | 0000 | 00000000 | 000 | ||

| Cutting Tool | 0000000 | Each | 000000 |