How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

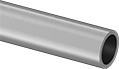

About Metal Tubing

More

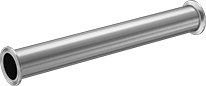

Smooth-Bore Seamless Stainless Steel Tubing

Seamless construction with no weld bead gives this tubing an interior with unrestricted flow. It is stronger than welded tubing and can be flared without splitting.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

Tubing that meets ASTM specifications adheres to international standards for dimensions and materials.

- Temperature Range: See Table

- Bending Method: Tube Bender

- For Use With: Natural Gas, Water, Oil, Air

- Compatible Tubing Fittings: Butt Weld, Compression, Flared, and Yor-Lok

| OD | Wall Thick. | ID | Max. Pressure | Temperature Range, °F | Temper Rating | Specifications Met | 8" | |

304 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/16" | 0.02" | 0.023" | 12,900 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/8" | 0.02" | 0.085" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/8" | 0.035" | 0.055" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/16" | 0.035" | 0.118" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.028" | 0.194" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.035" | 0.18" | 4,300 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.049" | 0.152" | 6,100 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 5/16" | 0.028" | 0.257" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/8" | 0.035" | 0.305" | 2,900 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/8" | 0.049" | 0.277" | 4,100 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/8" | 0.065" | 0.245" | 5,400 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/2" | 0.035" | 0.43" | 2,300 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/2" | 0.049" | 0.402" | 3,200 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/2" | 0.065" | 0.37" | 4,300 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 5/8" | 0.049" | 0.527" | 3,100 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/4" | 0.065" | 0.62" | 3,450 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1" | 0.065" | 0.87" | 2,600 psi @ 72° F | -425° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

316 Stainless Steel | ||||||||

| 1/16" | 0.02" | 0.023" | 12,900 psi @ 72° F | -325° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/8" | 0.02" | 0.085" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/8" | 0.035" | 0.055" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/16" | 0.035" | 0.118" | 7,400 psi @ 72° F | -325° to 1500° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.028" | 0.194" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.035" | 0.18" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.049" | 0.152" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 1/4" | 0.065" | 0.12" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/8" | 0.035" | 0.305" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

| 3/8" | 0.065" | 0.245" | Not Rated | -425° to 1000° | Soft | ASTM A213, ASTM A269 | 000000000 | |

Miniature Stainless Steel Tubing

Also known as hypodermic or needle tubing, this tubing has thin walls and is made to tight tolerances for use in precision applications. It is welded with a smoothed weld bead on the inside to reduce particle buildup. Tubing connects by welding. To cut this tubing, you can use abrasive cutoff wheels and deburring tools or electrolytic cutting tools (not included).

304 stainless steel has very good corrosion resistance.

- Temperature Range: Not Rated

- Bending Method: Tube Bender

| OD | Wall Thick. | ID | Tubing Needle Gauge | Temper Rating | 8" | |

304 Stainless Steel—For Use With Air, Natural Gas, Oil, Water | ||||||

|---|---|---|---|---|---|---|

| 0.016" | 0.004" | 0.008" | 27 | Hard | 00000000 | |

| 0.018" | 0.004" | 0.01" | 26 | Hard | 00000000 | |

| 0.02" | 0.005" | 0.01" | 25 | Hard | 00000000 | |

| 0.022" | 0.005" | 0.012" | 24 | Hard | 00000000 | |

| 0.025" | 0.006" | 0.013" | 23 | Hard | 00000000 | |

| 0.028" | 0.006" | 0.016" | 22 | Hard | 00000000 | |

| 0.032" | 0.006" | 0.02" | 21 | Hard | 00000000 | |

| 0.036" | 0.006" | 0.024" | 20 | Hard | 00000000 | |

| 0.042" | 0.008" | 0.027" | 19 | Hard | 0000000 | |

| 0.05" | 0.009" | 0.033" | 18 | Hard | 0000000 | |

| 0.065" | 0.009" | 0.047" | 16 | Hard | 0000000 | |

| 0.072" | 0.009" | 0.054" | 15 | Hard | 0000000 | |

| 0.083" | 0.01" | 0.063" | 14 | Hard | 0000000 | |

| 0.095" | 0.012" | 0.071" | 13 | Hard | 0000000 | |

| 0.109" | 0.012" | 0.085" | 12 | Hard | 00000000 | |

| 0.12" | 0.013" | 0.094" | 11 | Hard | 00000000 | |

| 0.134" | 0.014" | 0.106" | 10 | Hard | 00000000 | |

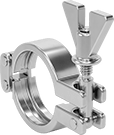

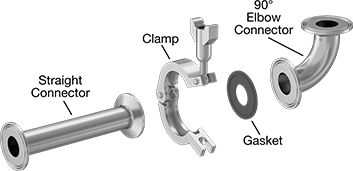

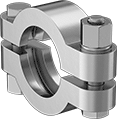

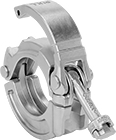

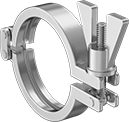

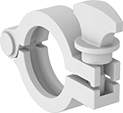

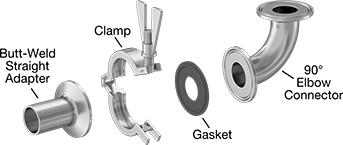

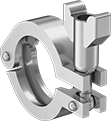

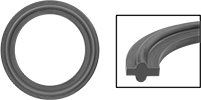

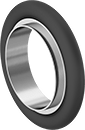

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing: Use with welded stainless steel that meets ASTM A269 or ASTM A270

- Specifications Met: See table

| For Tube OD | Flange OD | Specifications Met | 8" Lg. | |

304 Stainless Steel | ||||

|---|---|---|---|---|

| 1/2" | 0.984" | 3-A Certified 63-03 | 0000000 | |

| 3/4" | 0.984" | 3-A Certified 63-03 | 0000000 | |

| 1" | 1.984" | 3-A Certified 63-03 | 0000000 | |

| 1 1/4" | 2" | 3-A Certified 63-04 | 00000000 | |

| 1 1/2" | 1.984" | 3-A Certified 63-03 | 0000000 | |

| 2" | 2.516" | 3-A Certified 63-03 | 0000000 | |

| 2 1/2" | 3.047" | 3-A Certified 63-03 | 0000000 | |

| 3" | 3.579" | 3-A Certified 63-03 | 0000000 | |

| 4" | 4.682" | 3-A Certified 63-03 | 0000000 | |

| 6" | 6.57" | 3-A Certified 63-03 | 0000000 | |

316/316L Stainless Steel | ||||

| 1/2" | 0.984" | 3-A Certified 63-03 | 00000000 | |

| 3/4" | 0.984" | 3-A Certified 63-03 | 00000000 | |

| 1" | 1.984" | 3-A Certified 63-03 | 00000000 | |

| 1 1/2" | 1.984" | 3-A Certified 63-03 | 00000000 | |

| 2" | 2.516" | 3-A Certified 63-03 | 00000000 | |

| 2 1/2" | 3.047" | 3-A Certified 63-03 | 00000000 | |

| 3" | 3.579" | 3-A Certified 63-03 | 00000000 | |

| 4" | 4.682" | 3-A Certified 63-03 | 00000000 | |

| 6" | 6.57" | 3-A Certified 63-03 | 00000000 | |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/4", 3/8", 1/2", 5/8", 3/4" | 0.984" | 1,200 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 450 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2 1/2" | 3.047" | 400 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 4" | 4.682" | 200 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 6" | 6.57" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 1,200 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.516" | 450 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2 1/2" | 3.047" | 400 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 4" | 4.682" | 200 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 00000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2 1/2" | 3.047" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 4" | 4.682" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 6" | 6.57" | 304 Stainless Steel | 300 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 000000 |

| 2" | 2.516" | 450 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 00000 |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 00000 |

| 4" | 4.682" | 300 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 00000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1/2", 3/4" | 0.984" | 700 psi @ 72° F | 0000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 00000 |

| 2" | 2.516" | 700 psi @ 72° F | 0000000 | 00000 |

| 2 1/2" | 3.047" | 700 psi @ 72° F | 0000000 | 00000 |

| 3" | 3.579" | 580 psi @ 72° F | 0000000 | 00000 |

| 4" | 4.682" | 500 psi @ 72° F | 0000000 | 00000 |

| 6" | 6.57" | 430 psi @ 72° F | 0000000 | 00000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 316 Stainless Steel | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| 2" | 2.516" | 316 Stainless Steel | 1,300 psi @ 72° F | ASME BPVC.VIII | 0000000 | 000000 |

| 3" | 3.579" | 316 Stainless Steel | 1,300 psi @ 72° F | ASME BPVC.VIII | 0000000 | 000000 |

| 4" | 4.682" | 316 Stainless Steel | 820 psi @ 72° F | ASME BPVC.VIII | 0000000 | 000000 |

| 6" | 6.57" | 316 Stainless Steel | 210 psi @ 72° F | ASME BPVC.VIII | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2 1/2" | 3.047" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 4" | 4.682" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 6" | 6.57" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

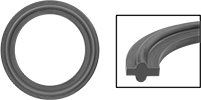

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 0.380" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

EPDM Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.670" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Silicone Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Fluoroelastomer Rubber | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 1/2" | 0.380" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3/4" | 0.620" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2 1/2" | 2.400" | 3.050" | 0.17" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 4" | 3.870" | 4.680" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 6" | 5.820" | 6.510" | 0.19" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 00000 |

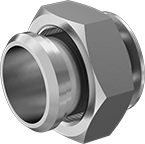

For Tube OD | |||||||

|---|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Includes | Each | |

| 1" | 1" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 0000000 |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

| 2" | 2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

| 2 1/2" | 2 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 000000 |

For Tube OD | ||||||

|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 2" | 2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 2 1/2" | 2 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 00000 |

| 2" | 2.64" | 2.516" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

| 3" | 3.87" | 3.579" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

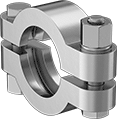

Extra-High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- For Use With: Air, Beverage, Dairy, Deionized Water, Food, Pharmaceuticals, Water

- Temperature Range: See Gaskets

- Tubing:

Fittings with 700 psi @ 72° F max. pressure: Use with 316/316L stainless steel that meets ASTM A269 or ASTM A270

Fittings with all other max. pressures: Use with 316/316L stainless steel that meets ASTM A249, ASTM A269, or ASTM A270

Gaskets: Use with 304/304L and 316/316L stainless steel - Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

Polished to a 20 Ra finish, these fittings have an extra-smooth interior that prevents product buildup and inhibits bacteria growth. Use them in pharmaceutical and bioprocessing applications. Also known as tri-clamp fittings, they connect with a clamp, a gasket, and another quick-clamp fitting for a fast and easy way to access your line. Fittings are 316 stainless steel for excellent corrosion resistance.

The pressure rating of the fitting will depend on the clamp you choose.

The temperature rating of the fitting will vary depending on the gasket material you choose.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

| For Tube OD | Flange OD | Length | Material | Max. Pressure | Specifications Met | Each | |

| 3/4" | 0.984" | 8" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 0000000 |

| 1" | 1.984" | 8" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 000000 |

| 1 1/2" | 1.984" | 8" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 000000 |

| 2" | 2.516" | 8" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 000000 |

| 3" | 3.579" | 8" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/4", 3/8", 1/2", 5/8", 3/4" | 0.984" | 1,200 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 450 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 350 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 304 Stainless Steel | 1,000 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1/2", 3/4" | 0.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 2" | 2.516" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

| 3" | 3.579" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 00000 |

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3/4" | 0.620" | 0.860" | 0.178" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 2" | 1.900" | 2.520" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 3" | 2.900" | 3.580" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

EPDM Rubber | ||||||||

| 3/4" | 0.620" | 0.860" | 0.178" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 3/4" | 0.620" | 0.860" | 0.178" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 3/4" | 0.620" | 0.860" | 0.178" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 3/4" | 0.620" | 0.860" | 0.178" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 2" | 1.900" | 2.520" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 3" | 2.900" | 3.580" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

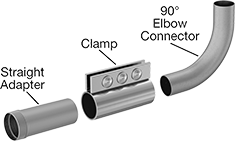

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

316 stainless steel fittings have excellent corrosion resistance.

ASME BPE fittings are polished to a 20 Ra finish for an extra-smooth interior that prevents product buildup and bacteria growth. Use them in pharmaceutical and bioprocessing applications.

316/316L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Temp. Range, °F | Length | Wall Thick. | For Use With | Specifications Met | Certification | Each | |

Polished | |||||||||

| 4" | 200 psi @ 72° F | -65° to 200° | 8" | 0.083" | Air, Deionized Water, Pharmaceuticals, Water | ASME BPE | Material Certificate with Traceable Lot Number and Test Report | 000000000 | 0000000 |

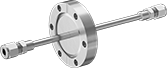

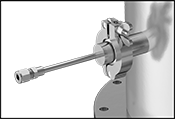

Flanged Through-Wall Fittings for Ultra-High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

Bolt these fittings onto your ultra-high-vacuum chamber to transfer liquids and gases inside. Also known as feedthroughs, they come assembled with a flanged (CF) fitting, metal tubing, and two Yor-Lok tube fittings. Their bolt-together connection forms the tightest seal of any fitting type, so you can use them in semiconductor manufacturing, surface analysis experiments, and even research with particle accelerators. Made of stainless steel and copper, these fittings resist rusting. These fittings are not for use in pressure applications.

To complete the flanged connection, you’ll need a gasket and bolt kit (each sold separately). The Yor-Lok fittings on each end include a nut and two sleeves that grip your system’s stainless steel tubing.

Bolt Holes | For Tube | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Bolt Circle Dia. | Dia. | No. of | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Acetone, Air, Ammonium Hydroxide, Helium, Methane, Nitrogen, Oil, Water | |||||||||||||

| 1 21/64" | 16 | CF | 1 1/16" | 11/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -13 torr @ 72° F | 304 Stainless Steel | 0000000 | 0000000 |

| 2 3/4" | 40 | CF | 2 5/16" | 17/64" | 6 | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -13 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

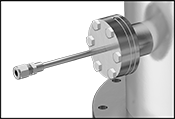

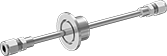

Quick-Clamp Through-Wall Fittings for High-Vacuum Chambers

- For Use With: See table

- Environment Temperature Range: 32° to 300° F

- Process Temperature Range: -325° to 995° F

- Tubing: Use with 304/304L or 316/316L stainless steel

- Specifications Met: ISO 2861

Transfer liquids and gases into high-vacuum chambers with these assembled fittings, also known as feedthroughs. Their quick-clamp (ISO-KF) connections are easier to install and remove than bolt-on flanges. This makes them a good choice for systems that need frequent cleaning, repairs, and setup changes, such as those in teaching and research labs. These fittings meet ISO 2861, which means they’re made to strict dimensional standards that ensure vacuum-tight connections. Made of stainless steel and aluminum, these fittings resist rusting. They are not for use in pressure applications.

These fittings are ready to install and include quick-clamp fittings, metal tubing, and Yor-Lok tube fittings at each end. The Yor-Lok fittings include a nut and two sleeves that grip your system’s stainless steel tubing. To complete the quick-clamp connection, you’ll need a clamp and ring (each sold separately).

For Tube | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Flange OD | High-Vacuum Flange Size | High Vacuum Connection Type | Connection Style | OD | Wall Thick. | Lg. | Max. Vacuum | Material | Each | |

For Use With Acetone, Air, Ammonium Hydroxide, Helium, Methane, Nitrogen, Oil, Water | ||||||||||

| 1.18" | 16 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 0000000 |

| 1.57" | 25 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| 2.16" | 40 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| 2.95" | 50 | ISO-KF | Yor-Lok | 1/4" | 0.028"-0.095" | 8" | 10 -8 torr @ 72° F | 304 Stainless Steel | 0000000 | 000000 |

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

With Wing Nut | ||||||

|---|---|---|---|---|---|---|

| 1.18" | 10, 16 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 1.57" | 25 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.16" | 40 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.95" | 50 | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

Material | |||||||

|---|---|---|---|---|---|---|---|

| For Flange OD | For High-Vacuum Flange Size | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Each | |

| 1.18" | 16 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 1.57" | 25 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.16" | 40 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 2.95" | 50 | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 0000000 | 00000 |

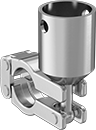

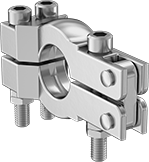

Clamps for Vacuum Fittings for Steel Tubing

Use these clamps to connect vacuum tube fittings. Insert two fittings into a clamp and tighten to form a secure seal.

- For Use With: Air, Glass, Plastic Pellets, Resins, Wood Chips

- Temperature Range: Neoprene Rubber Gaskets: -20° to 190° F

Silicone Rubber Gaskets: -100° to 500° F - Tubing: Use with steel

Bolt clamps have a stainless steel strip that provides an escape route for electrostatic buildup when used in a fully-grounded system. They have fair corrosion resistance.