About Foam

More

About Sanding Abrasives

More

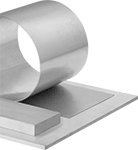

Multipurpose 6061 Aluminum Sheets and Bars

The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Extruded sheets and bars are formed by a die for close-tolerance widths, then cut to the lengths listed.

Aluminum that meets ASTM B209 or ASTM B221 complies with standards for materials.

Aluminum that meets an SAE AMS standard conforms to the material and process needs of the aerospace industry.

If you don’t see the sheet or bar size you need, please specify dimensions under additional sheet sizes or additional bar lengths.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: See table

- Fabrication: See table

- Specifications Met: See table

Oversized Multipurpose 6061 Aluminum Sheets

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: T651

- Fabrication: Hot Rolled

- Specifications Met: ASTM B209

The thickness is oversized to allow for finishing to exact requirements. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Fatigue-Resistant 7050 Aluminum

- Yield Strength: 68,000 psi

- Hardness: Not Rated

- Temper: T7451

- Fabrication: Cold Rolled

- Specifications Met: ASTM B594, SAE AMS4050

Substitute 7050 aluminum for 7075 in structural applications when high stress-corrosion resistance is required. It is the same material that's used for bulkheads and fuselage frames. These sheets are ultrasonically inspected (USI) for defects below the surface as per ASTM B594.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Multipurpose 4140 Alloy Steel Sheets and Bars

Also known as chrome-moly steel, this versatile alloy steel is used for a wide range of parts, such as molds and structural supports. It resists fracturing from repeated stress. You can also surface harden it with heat to add wear resistance. These sheets and bars are manufactured to ASTM standards for quality and performance.

Note: Sheets and bars may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Yield Strength: 60,000 psi

- Hardness: Rockwell B90 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C60

- Fabrication: Cold Worked

- Specifications Met: ASTM A108

3" Lg. | ||||||

|---|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Wd. | Heat Treatment | Straightness Tolerance | Each | |

| 2 3/4" | -0.009" to 0" | 2 3/4" | Annealed (Softened) | 3/16" per 10 ft. | 00000000 | 000000 |

Low-Carbon Steel Sheets and Bars

Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into parts that don’t require high strength, such as fixture clamps and mounting plates.

Heat treatable material can be surface hardened for added wear resistance.

Steel that meets ASTM specifications complies with standards for manufacturing and performance.

Easy-to-Machine Gray Cast Iron Sheets and Bars

- Yield Strength: Not Rated

- Hardness: Rockwell C20 (Hard)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C50

- Specifications Met: ASTM A247

Gray cast iron machines faster with less wear on cutting tools than most types of steel. It also absorbs vibration, so finished parts run quieter than those made of steel. It's often fabricated into gears, pulleys, and bushings.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

1 ft. Lg. | ||

|---|---|---|

| Wd. | Straightness Tolerance | |

2 3/4" Thick. | ||

| 12 1/4" | 1/8" per 6 ft. | 0000000 |

Wear-Resistant Easy-to-Machine Delrin® Acetal Resin Sheets, Bars, and Strips

These sheets, bars, and strips resist expanding when exposed to heat and moisture, so they can be easily machined to close tolerances. They also have a naturally slippery, wear-resistant surface. Use them to make precision gears, bushings, and bearings. Delrin® acetal resin, also known as acetal homopolymer, is stronger and stiffer than acetal copolymer.

White sheets, bars, and strips are FDA compliant for contact with food.

- Color: White or Black

- Temperature Range: -20° to 180° F

- Tensile Strength: 10,000-11,000 psi (Good)

- Impact Strength: 1-1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R120-R122 (Hard)

- For Use Outdoors: No

- Specifications Met:

White: ASTM D6100, FDA Compliant 21 CFR 177.2480, NSF/ANSI 51, NSF/ANSI 61

Black: ASTM D6100

White | Black | ||||

|---|---|---|---|---|---|

| Thick. | Thick. Tolerance | Each | Each | ||

6" × 6" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 0000000 | 00000000 | 0000000 |

12" × 12" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 000000 | 00000000 | 000000 |

12" × 24" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 000000 | 00000000 | 000000 |

12" × 48" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 00000000 | 00000000 | 00000000 |

24" × 24" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 00000000 | 00000000 | 00000000 |

24" × 48" | |||||

| 2 3/4" | 0" to 0.05" | 00000000 | 00000000 | 00000000 | 00000000 |

Super-Cushioning Polyurethane Foam Sheets, Bars, Cubes, and Strips

Durable enough to be used in seat cushions, this flexible polyurethane foam provides gentle cushioning support. Use these sheets, bars, cubes, and strips in packaging applications to absorb shock and damp vibration. Foam has open-cell construction, which allows water, air, and gases to be absorbed.

- Color: Gray

- Temperature Range: -20° to 180° F

- Cell Type: Open

- For Use Outdoors: No

- Density: 1.5 lbs./cu. ft.

- Pressure to Compress 25%: 0.5 psi (Ultra Soft)

- Tensile Strength Rating: Fair

- Oil-Resistance Rating: Not Rated

| Thick. | Thick. Tolerance | Wd. | Lg. | Each | |

| 2 3/4" | -0.125" to 0.125" | 2 3/4" | 2 3/4" | 0000000 | 00000 |

Sanding Sponges for Corners

Evenly sand two surfaces at once. These sponges provide the comfort and control of a sanding block while remaining flexible. The abrasive is on two sides.

| Grit | Wd. | Lg. | Thick. | For Use On | Abrasive Material | Abrasive Backing Material | Each | |

For Smooth Finish | ||||||||

|---|---|---|---|---|---|---|---|---|

| 120 | 2 3/4" | 4 1/2" | 2 3/4" | Steel, Wood | Aluminum Oxide | Foam | 0000000 | 00000 |