Filter by

Attachment Type

Application

Thread Size

Fitting Type

Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Overall Length

REACH

RoHS

Sleeve Diameter

Specifications Met

Thread Length

Required Installation Tool

Wire Rope Construction

Weight Capacity

Length

Finish

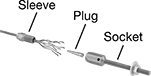

Stud-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Thread | Steel | Zinc-Plated Steel | 316 Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Overall Lg. | Size | Lg. | Sleeve Dia. | Wt. Cap., lb. | Specs. Met | Each | Each | Each | ||||

| 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 11" | 7/8"-14 | 6 15/16" | 1 7/16" | 5,300 | ASME B30.26 ASME B30.9 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 0000000 | |