Filter by

Thread Size

Screw Size

Anchor Type

Performance

For Use In

Usable Length

Connection Hardware

Thread Direction

Specifications Met

Threading

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Thread Spacing

Thread Type

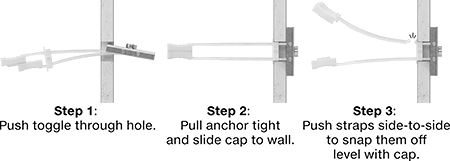

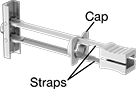

High-Strength Toggle Anchors for Drywall

|  |

Ultimate Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Thread Size | Usable Lg., mm | Drill Bit Size, mm | Wing Span, mm | Toggle Material | Material | Pull-Out, lbf | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| M10 × 1.5 mm | 10 to 64 | 19 | 51 | Zinc-Plated Steel | Polystyrene | 270 | Not Rated | 1/2" Drywall | 5 | 000000000 | 000000 | |

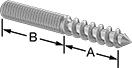

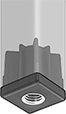

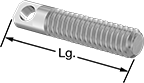

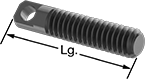

Thread-Mount Studs for Wood

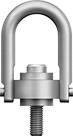

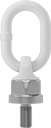

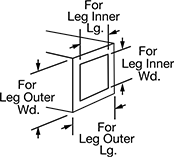

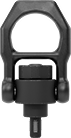

Hoist Rings—For Lifting

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg., mm | Inside Wd., mm | Overall Ht., mm | Vert. Cap., lb. | Movement | Specs. Met | Certification | Mil. Spec. | 1-9 | 10-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 16 | 33 | 98 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 26 | 33 | 108 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machined Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 | 21 | 86 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Fluorescent Green Powder-Coated Steel—High Visibility | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 16 | 33 | 98 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 16 | 33 | 98 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machined Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 | 21 | 86 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged 17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15 | 38 | 106 | 975 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machined 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 18 | 22 | 86 | 550 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked, Mil. Spec. | MIL-STD-1365, MIL-STD-209 | 0000000 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

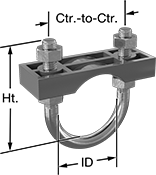

Parallel Beam-to-Beam Clamps

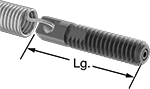

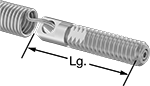

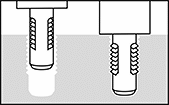

Corrosion-Resistant Extension Spring Stud Anchors

|

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Min. Lg., mm | Spacing | Lg., mm | Dia., mm | Hole Dia., mm | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 28 | Coarse | 41 | 10 | 6 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swiveling Extension Spring Stud Anchors

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Min. Lg., mm | Spacing | Lg., mm | Dia., mm | Hole Dia., mm | Hex Size, mm | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 28 | Coarse | 41 | 10 | 6 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extension Spring Stud Anchors

|

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Min. Lg., mm | Spacing | Lg., mm | Dia., mm | Hole Dia., mm | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 28 | Coarse | 41 | 10 | 6 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Swiveling Extension Spring Stud Anchors

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Min. Lg., mm | Spacing | Lg., mm | Dia., mm | Hole Dia., mm | Hex Size, mm | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 28 | Coarse | 41 | 10 | 6 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Beam Clamps for Threaded Rods

Style | For Beam Shape | For Thread Size | For Max. Beam Thk. | Wt. Cap., lb. | Mount Type | Throat Dp. | Lg. | Wd. | Ht. | Threaded Rod Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Bottom Beam Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | Flat, Taper | M10 × 1.5 mm | 3/4" | 525 | Clamp On | 1/2" | 1 5/8" | 1 5/8" | 1 3/4" | No | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

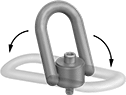

Swivel-Under-Load Hoist Rings—For Lifting

Thread Size | Thread Lg., mm | Inside Wd., mm | Overall Ht., mm | Vert. Cap., lb. | Movement | Specs. Met | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Forged Yellow Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 20 | 35 | 145 | 1,760 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Side-Mount Hoist Rings—For Lifting

Thread Size | Thread Lg., mm | Inside Wd., mm | Overall Ht., mm | Vert. Cap., lb. | Movement | Specs. Met | Certification | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

D-Shape | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 20 | 45 | 101 | 1,100 | 180° Pivot and 360° Swivel | ASME B30.26 | CE Marked | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 24 | 74 | 154 | 990 | 180° Pivot and 360° Swivel | ASME B30.26 | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forged Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 24 | 38 | 144 | 990 | 180° Pivot and 360° Swivel | ASME B30.26 | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

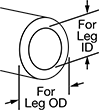

Clamping U-Bolts

ID | Thread | Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inch | Metric, mm | For Pipe Size | Ht. | Lg. | Pitch, mm | Wt. Cap. | Ctr.-to-Ctr. | Material | Color | Lg. | Wd. | Thk. | No. of Nuts Included | Temp. Range, ° F | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M10 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.1875" | 30 | 3/4 | 2 3/8" | 1 5/8" | 1.5 | Not Rated | 1 9/16" | Plastic | Black | 2 15/16" | 1 3/16" | 1/2" | 4 | -20 to 190 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5" | 38 | 1 | 2 9/16" | 1 5/8" | 1.5 | Not Rated | 1 7/8" | Plastic | Black | 3 1/8" | 1 3/16" | 1/2" | 4 | -20 to 190 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.8125" | 46 | 1 1/4 | 3" | 2" | 1.5 | Not Rated | 2 3/16" | Plastic | Black | 3 9/16" | 1 3/16" | 1/2" | 4 | -20 to 190 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.0625" | 52 | 1 1/2 | 3 1/4" | 2" | 1.5 | Not Rated | 2 7/16" | Plastic | Black | 3 3/4" | 1 3/8" | 19/32" | 4 | -20 to 190 | 1 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||