About Plastic

More

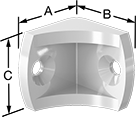

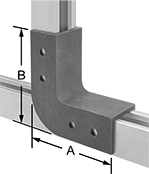

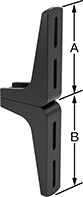

Corner Brackets

Also known as angle brackets.

Corner Strut Channel Brackets

Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Style | (A) | (B) | Thick. | Temperature Range, °F | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | ||||||||

Gray Plastic | ||||||||

| 1 | 1 7/8" | 1 7/8" | 3/8" | -40° to 140° | 7/16" | No | 000000000 | 000000 |

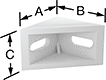

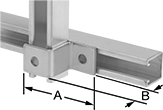

Offset-Surface Strut Channel Brackets

Plastic brackets are nonconductive and lightweight with good resistance to chemicals.

Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Strut Channel Ht. | (A) | (B) | Thick. | Temperature Range, °F | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | ||||||||

Gray Plastic | ||||||||

| 1 5/8" | 5 7/16" | 1 7/8" | 1/4" | -40° to 140° | 7/16" | No | 000000000 | 000000 |

Lg. | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Strut Channel Ht. | (A) | (B) | Thick. | Temperature Range, °F | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | ||||||||

Gray Plastic | ||||||||

| 1 5/8" | 3 1/2" | 1 7/8" | 1/4" | -40° to 140° | 9/16" | No | 000000000 | 000000 |

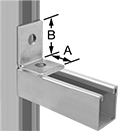

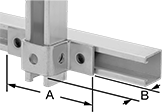

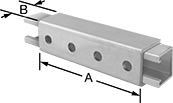

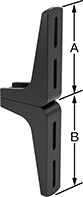

Wraparound Strut Channel Brackets

Designed to wrap around the sides of strut channel, these brackets provide a stronger hold than other strut channel brackets.

Plastic brackets are nonconductive and lightweight with good resistance to chemicals.

Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Style | For Strut Channel Ht. | (A) | (B) | Thick. | Temperature Range, °F | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | |||||||||

Gray Plastic | |||||||||

| 3 | 1 5/8" | 7 1/4" | 1 7/8" | 1/4" | -40° to 140° | 9/16" | No | 000000000 | 000000 |

Lg. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Style | For Strut Channel Ht. | (A) | (B) | Thick. | Temperature Range, °F | Hole Dia. | Fasteners Included | Each | |

For 1 5/8" Channel Wd. | |||||||||

Gray Plastic | |||||||||

| 6 | 1 5/8" | 4 7/8" | 4 7/8" | 3/16" | -40° to 140° | 3/8" | No | 00000000 | 000000 |

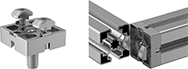

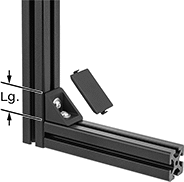

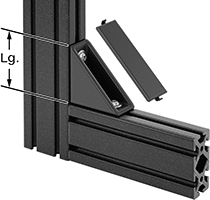

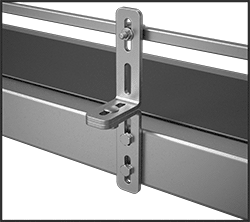

T-Slotted Framing Structural Brackets

Connect T-slotted rails and reinforce joints for structural stability. Fasteners are included.

Concealed brackets mount internally and stay out of sight once installed.

Plate connector concealed brackets create a structural bracket connection point on the end of one rail that can attach at a 90° angle along another rail. They have a screw on one side and a T-slot nut on the other. Tap a hole in the end of one rail and thread in the screw. Then slide the T-slot nut into the slot of the other rail. Brackets with no required tap thread size include thread-forming screws.

For Rail Ht., mm | |||||||

|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Color | Material | Rail Machining | Mounting Fasteners Included | Each | |

| 40 | 80 | Black | Plastic | Not Required | Yes | 0000000 | 000000 |

T-Slotted Framing Mounting Brackets

Attach sensors, tubes, and other components to T-slotted framing rails and structures.

Sensor holders are compatible with laser sensors, photo eyes, and light-sensing switches.

For Rail Ht. | ||||||||

|---|---|---|---|---|---|---|---|---|

| Single | Double and Quad | Triple | For Sensor OD, mm | Color | Material | Mounting Fasteners Included | Each | |

Fixed | ||||||||

| 1" | 2" | 3" | 12 | Black | Plastic | Yes | 00000000 | 00000 |

| 1" | 2" | 3" | 18 | Black | Plastic | Yes | 000000000 | 0000 |

| 1 1/2", 30mm, 40mm | 3", 60mm, 80mm | 4 1/2", 120mm | 12 | Black | Plastic | Yes | 00000000 | 0000 |

| 1 1/2", 40mm | 3", 80mm | 4 1/2", 120mm | 18 | Black | Plastic | Yes | 00000000 | 0000 |

| 45mm | 90mm | __ | 12 | Black | Plastic | Yes | 00000000 | 0000 |

| 45mm | 90mm | __ | 18 | Black | Plastic | Yes | 00000000 | 0000 |

Adhesive-surface mounting strips attach lightweight objects to T-slotted framing without the need for fasteners.

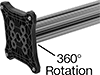

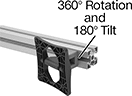

T-Slotted Framing Mounts for Monitors and Computer Accessories

Attach and position phones, tablets, monitors, and computer accessories on T-slotted rails.

Monitor mounts have a VESA (Video Electronics Standards Association) standard mounting hole pattern, so they will match most monitors. They fit in tight spaces because they mount directly to T-slotted rails. Friction monitor mounts stay in place if bumped, but they require you to move the entire weight of the monitor.

For Rail Ht. | Overall | Monitor | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Single | Double, Quad | Triple | Projection | Ht. | Wd. | Max. Load Capacity, lbs. | For Monitor Size | Mount Type | Mounting Hole Pattern Compatibility | Color | Material | Mounting Fasteners Included | Each | |

Rotate | |||||||||||||||

| A | 1 1/2" 40mm 45mm | 3" 80mm 90mm | 4 1/2" 120mm | 1" | 4 1/2" | 4 1/2" | 10 | 12"-24" | Friction | VESA 75 × 75 VESA 100 × 100 | Black | Plastic | Yes | 0000000 | 000000 |

Rotate, Tilt | |||||||||||||||

| C | 1 1/2" 40mm | 3" 80mm | 4 1/2" 120mm | 3" | 4 7/16" | 4 7/16" | 10 | 12"-24" | Friction | VESA 75 × 75 VESA 100 × 100 | Black | Plastic | Yes | 000000000 | 00000 |

| C | 45mm | 90mm | __ | 3" | 4 7/16" | 4 7/16" | 10 | 12"-24" | Friction | VESA 75 × 75 VESA 100 × 100 | Black | Plastic | Yes | 0000000 | 00000 |

T-Slotted Framing Caps, Covers, and Seals

Seal T-slots, rail ends, and gaps between rails to keep out dust, debris, and other contaminants.

End caps protect the ends of rails from damage and keep out dust and grime.

| For Rail Ht. | Angle | Material | Color | Each | |

Push In | |||||

|---|---|---|---|---|---|

| 40mm | 45° | ABS Plastic | Black | 00000000 | 00000 |

End caps snap on to protect the ends of rails from damage and keep out dust and grime.

| For Rail Ht. | Angle | Includes | Material | Color | Each | |

Push In | ||||||

|---|---|---|---|---|---|---|

| 40mm | 45° | Push-In Rivet | ABS Plastic | Black | 00000000 | 00000 |

End caps protect the ends of rails from damage and keep out dust and grime.

| For Rail Ht. | Material | Color | Each | |

Push In | ||||

|---|---|---|---|---|

| 120mm | ABS Plastic | Black | 00000000 | 00000 |

For Rail Ht. | |||||

|---|---|---|---|---|---|

| Single, Single Radius Two Slot | Material | Color | Pkg. Qty. | Pkg. | |

| 40mm | Plastic | Black | 10 | 00000000 | 00000 |

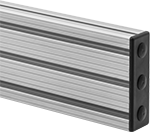

Lightweight Composite T-Slotted Framing and Fittings

Build lightweight structures, such as light duty machine guards, enclosures, and carts, with framing that is two-thirds the weight of aluminum framing. Made of 30% polypropylene and 70% wood, they’re not as strong as aluminum rails, but they’re nonconductive, easy to machine, and more corrosion resistant. Good for lab environments, they also withstand cleaning with chemicals better than aluminum. Use their continuous T-slots to attach fittings. They work with any T-slotted component for 40 mm rails that doesn’t require machining. View additional structural brackets and fasteners.

Brackets connect T-slotted composite rails for structural stability. Fasteners are included.

Corner brackets are also known as angle brackets. These brackets don’t require you to machine your rails.

Closed gusset brackets include a black plastic cover for a finished appearance.

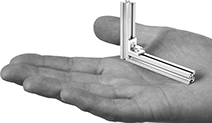

Miniature T-Slotted Framing and Fittings

Build test fixtures, prototypes, and other small structures with this miniature version of T-slotted framing and fittings. The framing has continuous T-slots for attaching fittings with the included mounting fasteners.

End caps snap on to protect the ends of rails from damage and keep out dust and grime.

Black | ||||

|---|---|---|---|---|

| For Rail Ht., mm | Mount Type | Pkg. Qty. | Pkg. | |

| 10 | Push In | 4 | 0000000 | 00000 |

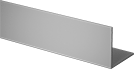

Chemical-Resistant PVC 90° Angles

- Color: Gray

- Temperature Range: 32° to 140° F

- Tensile Strength: 7,000-7,800 psi (Good)

- Impact Strength: 0.7-3 ft.-lbs./in. (Poor)

- Hardness: Rockwell R110-R120 (Hard)

- For Use Outdoors: No

Because these PVC Type 1 90° angles stand up to acids and alkalies, they’re often used to fabricate frames, tracks, and supports in chemical-processing applications. This material is easy to thermoform, plus it is an excellent electrical insulator.

Outside | Inside | 5 ft. Lg. | |||||

|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Each | |

0.08" Wall Thick. (-0.01" to 0.001") | |||||||

| 3/4" | 0.000" to 0.125" | 3/4" | 0.000" to 0.125" | 0.670" | 0.67" | 0000000 | 000000 |

0.08" Wall Thick. (-0.01" to 0.01") | |||||||

| 1/2" | 0.000" to 0.125" | 1/2" | 0.000" to 0.125" | 0.420" | 0.42" | 0000000 | 0000 |

| 3/4" | -0.125" to 0.125" | 1 1/2" | -0.125" to 0.125" | 0.670" | 1.42" | 0000000 | 00000 |

| 2" | -0.125" to 0.125" | 2" | -0.125" to 0.125" | 1.920" | 1.92" | 0000000 | 00000 |

1/8" Wall Thick. (-0.063" to 0.063") | |||||||

| 1" | -0.125" to 0.125" | 1" | -0.125" to 0.125" | 7/8" | 7/8" | 0000000 | 00000 |

1/8" Wall Thick. (-0.015" to 0.015") | |||||||

| 3/4" | -0.125" to 0.125" | 3" | -0.125" to 0.125" | 5/8" | 2 7/8" | 0000000 | 00000 |

| 1 1/4" | 0.000" to 0.040" | 1 1/4" | 0.000" to 0.040" | 1 1/8" | 1 1/8" | 0000000 | 00000 |

| 1 1/2" | 0.000" to 0.050" | 1 1/2" | 0.000" to 0.050" | 1 3/8" | 1 3/8" | 0000000 | 00000 |

| 2" | 0.000" to 0.060" | 2" | 0.000" to 0.060" | 1 7/8" | 1 7/8" | 0000000 | 00000 |

0.157" Wall Thick. (-0.019" to 0.019") | |||||||

| 3/4" | -0.125" to 0.125" | 1 1/2" | -0.125" to 0.125" | 0.593" | 1.343" | 0000000 | 00000 |

3/16" Wall Thick. (-0.063" to 0.063") | |||||||

| 1 1/4" | -0.125" to 0.125" | 1 1/4" | -0.125" to 0.125" | 1 1/16" | 1 1/16" | 0000000 | 00000 |

3/16" Wall Thick. (-0.023" to 0.023") | |||||||

| 1 1/2" | 0.000" to 0.050" | 1 1/2" | 0.000" to 0.050" | 1 5/16" | 1 5/16" | 0000000 | 00000 |

| 2" | 0.000" to 0.060" | 2" | 0.000" to 0.060" | 1 13/16" | 1 13/16" | 0000000 | 00000 |

1/4" Wall Thick. (-0.063" to 0.063") | |||||||

| 1 1/2" | 0.000" to 0.050" | 1 1/2" | 0.000" to 0.050" | 1 1/4" | 1 1/4" | 0000000 | 00000 |

| 2" | 0.000" to 0.060" | 2" | 0.000" to 0.060" | 1 3/4" | 1 3/4" | 0000000 | 00000 |

1/4" Wall Thick. (-0.03" to 0.03") | |||||||

| 1 1/4" | 0.000" to 0.040" | 1 1/4" | 0.000" to 0.040" | 1" | 1" | 0000000 | 00000 |

0.275" Wall Thick. (-0.033" to 0.033") | |||||||

| 2 3/8" | -0.125" to 0.125" | 2 3/8" | -0.125" to 0.125" | 2.100" | 2.1" | 0000000 | 00000 |

| 3 1/2" | -0.125" to 0.125" | 3 1/2" | -0.125" to 0.125" | 3.225" | 3.225" | 0000000 | 000000 |

Impact- and Chemical-Resistant PVC 90° Angles

- Color: Black

- Temperature Range: See table

- Tensile Strength: 5,600 psi (Good)

- Impact Strength: 20 ft.-lbs./in. (Excellent)

- Hardness: Durometer 80D (Hard)

- For Use Outdoors: Yes

- Specifications Met: UL 94 V-0, NSF/ANSI 51

Made of PVC Type 2 plastic, these 90° angles resist impact and chemicals. More impact resistant than PVC Type 1, PVC Type 2 is commonly used where protection from bumps and strikes is needed. It’s also more impact resistant than silicone, although not as resistant to heat. Since it stands up to acids and alkalies, it’s often used to make parts for chemical processing applications.

Outside | Inside | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Temperature Range, °F | 2 ft. Lg. | 4 ft. Lg. | 8 ft. Lg. | |

0.06" Wall Thickness (-0.01" to 0.01") | ||||||||||

| 1/2" | -0.01" to 0.01" | 1/2" | -0.01" to 0.01" | 0.44" | 0.44" | 40° to 140° | 00000000 | |||

| 1" | -0.02" to 0.02" | 1" | -0.02" to 0.02" | 0.94" | 0.94" | 40° to 140° | 00000000 | |||

0.06" Wall Thickness (-0.008" to 0.008") | ||||||||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.69" | 0.69" | 40° to 140° | 0000000 | |||

0.065" Wall Thickness (-0.01" to 0.01") | ||||||||||

| 1 1/2" | -0.025" to 0.025" | 1 1/2" | -0.025" to 0.025" | 1.435" | 1.435" | 40° to 140° | 00000000 | |||

0.1" Wall Thickness (-0.015" to 0.015") | ||||||||||

| 3/4" | -0.015" to 0.015" | 3/4" | -0.015" to 0.015" | 0.65" | 0.65" | 40° to 140° | 00000000 | |||

| 1" | -0.02" to 0.02" | 1" | -0.02" to 0.02" | 0.9" | 0.9" | 40° to 140° | 00000000 | |||

| 2" | -0.025" to 0.025" | 2" | -0.025" to 0.025" | 1.9" | 1.9" | 40° to 140° | 00000000 | |||

3/16" Wall Thickness (-0.02" to 0.02") | ||||||||||

| 1 1/2" | -0.025" to 0.025" | 1 1/2" | -0.025" to 0.025" | 1.312" | 1.312" | 40° to 140° | 00000000 | |||

| 2" | -0.025" to 0.025" | 2" | -0.025" to 0.025" | 1.812" | 1.812" | 40° to 140° | 00000000 | |||

Slippery UHMW Polyethylene 90° Angles

- Color: White

- Temperature Range: -20° F to 180° F

- Tensile Strength: 4,350-5,800 psi (Poor)

- Impact Strength: 16.8 ft.-lbs./in. (Excellent)

- Hardness: Durometer 65D-67D (Medium)

- For Use Outdoors: No

- Specifications Met: ASTM D4020, FDA Compliant 21 CFR 177.1520

Often used to fabricate frames and protect corners from impact, these UHMW 90° angles have a slippery surface that stands up to scuffs, scrapes, and strikes.

Outside | Inside | |||||||

|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Lengths, ft. | Per Ft. | |

1/8" Wall Thick. (-0.060" to 0.060") | ||||||||

| 1" | -0.060" to 0.060" | 1" | -0.060" to 0.060" | 7/8" | 7/8" | 0000000 | 00000 | |

| 1 1/2" | -0.060" to 0.060" | 1 1/2" | -0.060" to 0.060" | 1 3/8" | 1 3/8" | 0000000 | 0000 | |

| 2" | -0.060" to 0.060" | 2" | -0.060" to 0.060" | 1 7/8" | 1 7/8" | 0000000 | 0000 | |

1/4" Wall Thick. (-0.060" to 0.060") | ||||||||

| 5/8" | -0.060" to 0.060" | 1 1/2" | -0.060" to 0.060" | 3/8" | 1 1/4" | 0000000 | 0000 | |

| 1 1/2" | -0.060" to 0.060" | 1 1/2" | -0.060" to 0.060" | 1 1/4" | 1 1/4" | 0000000 | 0000 | |

| 2" | -0.060" to 0.060" | 2" | -0.060" to 0.060" | 1 3/4" | 1 3/4" | 0000000 | 0000 | |

1/2" Wall Thick. (-0.060" to 0.060") | ||||||||

| 3" | -0.060" to 0.060" | 3" | -0.060" to 0.060" | 2 1/2" | 2 1/2" | 0000000 | 00000 | |

| 3 1/2" | -0.060" to 0.060" | 3 1/2" | -0.060" to 0.060" | 3" | 3" | 0000000 | 00000 | |

Polypropylene 90° Angles

- Color: Semi-Clear White

- Temperature Range: -40° to 180° F

- Tensile Strength: 5,200 psi (Good)

- Impact Strength: 1.5 ft.-lbs./in. (Poor)

- Hardness: Rockwell R110 (Hard)

- For Use Outdoors: No

- Specifications Met: ASTM D4101, FDA Compliant 21 CFR 177.1520

Fabricate guide rails and parts for use in laboratories with these 90° angles. They’re polypropylene, so they have a hard, slippery surface that won’t stick to cutting tools. They also resist swelling when exposed to water.

Clear Impact-Resistant Polycarbonate 90° Angles

- Color: Clear

- Temperature Range: -40° to 200° F

- Tensile Strength: 8,960 psi (Good)

- Impact Strength: Not Rated

- Hardness: Rockwell R118 (Hard)

- For Use Outdoors: No

Often used when making display racks, machine guards, and other items you need to see through, these 90° angles are made of polycarbonate. This material is commonly known as Lexan, Hyzod, Tuffak, and Makrolon.

Outside | Inside | ||||||

|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Each | |

2ft. Lg. | |||||||

0.05" Wall Thick. (-0.005" to 0.005") | |||||||

| 1/2" | -0.020" to 0.020" | 1/2" | -0.020" to 0.020" | 0.45" | 0.45" | 0000000 | 00000 |

| 1" | -0.030" to 0.030" | 1" | -0.030" to 0.030" | 0.95" | 0.95" | 0000000 | 0000 |

| 1 1/2" | -0.030" to 0.030" | 1 1/2" | -0.030" to 0.030" | 1.45" | 1.45" | 0000000 | 0000 |

0.075" Wall Thick. (-0.01" to 0.01") | |||||||

| 1 1/8" | -0.030" to 0.030" | 1 1/8" | -0.030" to 0.030" | 1.05" | 1.05" | 0000000 | 0000 |

0.1" Wall Thick. (-0.01" to 0.01") | |||||||

| 2" | -0.030" to 0.030" | 2" | -0.030" to 0.030" | 1.9" | 1.9" | 0000000 | 00000 |

| 2 1/2" | -0.030" to 0.030" | 2 1/2" | -0.030" to 0.030" | 2.4" | 2.4" | 0000000 | 00000 |

0.105" Wall Thick. (-0.015" to 0.015") | |||||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2.9" | 2.9" | 0000000 | 00000 |

4ft. Lg. | |||||||

0.05" Wall Thick. (-0.005" to 0.005") | |||||||

| 1/2" | -0.020" to 0.020" | 1/2" | -0.020" to 0.020" | 0.45" | 0.45" | 0000000 | 0000 |

| 1" | -0.030" to 0.030" | 1" | -0.030" to 0.030" | 0.95" | 0.95" | 0000000 | 00000 |

| 1 1/2" | -0.030" to 0.030" | 1 1/2" | -0.030" to 0.030" | 1.45" | 1.45" | 0000000 | 00000 |

0.075" Wall Thick. (-0.01" to 0.01") | |||||||

| 1 1/8" | -0.030" to 0.030" | 1 1/8" | -0.030" to 0.030" | 1.05" | 1.05" | 0000000 | 00000 |

0.1" Wall Thick. (-0.01" to 0.01") | |||||||

| 2" | -0.030" to 0.030" | 2" | -0.030" to 0.030" | 1.9" | 1.9" | 0000000 | 00000 |

| 2 1/2" | -0.030" to 0.030" | 2 1/2" | -0.030" to 0.030" | 2.4" | 2.4" | 0000000 | 00000 |

0.105" Wall Thick. (-0.015" to 0.015") | |||||||

| 3" | -0.030" to 0.030" | 3" | -0.030" to 0.030" | 2.9" | 2.9" | 0000000 | 00000 |

6ft. Lg. | |||||||

0.05" Wall Thick. (-0.005" to 0.005") | |||||||

| 1/2" | -0.020" to 0.020" | 1/2" | -0.020" to 0.020" | 0.45" | 0.45" | 00000000 | 0000 |

| 1" | -0.030" to 0.030" | 1" | -0.030" to 0.030" | 0.95" | 0.95" | 00000000 | 00000 |

| 1 1/2" | -0.030" to 0.030" | 1 1/2" | -0.030" to 0.030" | 1.45" | 1.45" | 00000000 | 00000 |

Straight and L-Brackets for Conveyors

These brackets mount to the frame of a conveyor to hold guide rails and accessories.

Two-piece L-brackets allow for offset mounting and extra clearance between the conveyor and guide rail or sensor.

Ht. | |||||||

|---|---|---|---|---|---|---|---|

| Wd. | Ht. | (A) | (B) | Material | Each | ||

| G | 3 5/8" | 11 3/4" | 5.85" | 5.85" | Plastic | 0000000 | 000000 |