Filter by

System of Measurement

OD

Overall Length

Point Diameter

Head Diameter

Shank Type

For Holding

Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Length

Total Indicated Runout (TIR) Accuracy

Collet Type

Expanding-End Lathe Mandrels

|

OD | Overall Lg. | Shank Dia. | End Expansion | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1/4" | 3" | 1/4" | 0.002" | Steel | 2779A11 | 000000 | |

| 3/8" | 3" | 3/8" | 0.002" | Steel | 2779A12 | 00000 | |

| 1/2" | 3" | 1/2" | 0.002" | Steel | 2779A13 | 00000 | |

| 5/8" | 3" | 5/8" | 0.002" | Steel | 2779A14 | 00000 | |

| 3/4" | 4" | 3/4" | 0.002" | Steel | 2779A21 | 00000 | |

| 7/8" | 4" | 7/8" | 0.002" | Steel | 2779A22 | 00000 | |

| 1" | 4" | 1" | 0.002" | Steel | 2779A23 | 00000 | |

| 1 1/4" | 4" | 1" | 0.002" | Steel | 2779A24 | 00000 | |

| 1 1/2" | 4" | 1" | 0.002" | Steel | 2779A25 | 00000 | |

| 1 3/4" | 4" | 1" | 0.002" | Steel | 2779A26 | 00000 |

Solid Lathe Mandrels

|

OD | Overall Lg. | Taper per In. | Tapered End Tolerance | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1/8" | 2 1/2" | 0.0005" | -0.0005", 0" | Steel | 3277A11 | 000000 | |

| 3/16" | 3" | 0.0005" | -0.0005", 0" | Steel | 3277A13 | 00000 | |

| 1/4" | 3 3/4" | 0.0005" | -0.0005", 0" | Steel | 3277A14 | 00000 | |

| 5/16" | 4" | 0.0005" | -0.0005", 0" | Steel | 3277A15 | 00000 | |

| 3/8" | 4 1/4" | 0.0005" | -0.0005", 0" | Steel | 3277A16 | 00000 | |

| 7/16" | 4 1/2" | 0.0005" | -0.0005", 0" | Steel | 3277A17 | 00000 | |

| 1/2" | 5" | 0.0005" | -0.0005", 0" | Steel | 3277A18 | 00000 | |

| 9/16" | 5 1/4" | 0.0005" | -0.0005", 0" | Steel | 3277A19 | 00000 | |

| 5/8" | 5 1/2" | 0.0005" | -0.0005", 0" | Steel | 3277A23 | 00000 | |

| 3/4" | 6" | 0.0005" | -0.0005", 0" | Steel | 3277A25 | 00000 | |

| 7/8" | 6 1/2" | 0.0005" | -0.0005", 0" | Steel | 3277A27 | 00000 | |

| 1" | 7" | 0.0005" | -0.0005", 0" | Steel | 3277A29 | 00000 |

Wide-Diameter Range Lathe Mandrels

OD | Overall Lg. | Sleeve Lg. | Total Indicated Runout (TIR) Accuracy | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 1/2" to 9/16" | 5" | 2 1/2" | 0.001" | Steel | 3276A31 | 000000 | |

| 9/16" to 21/32" | 6" | 2 3/4" | 0.001" | Steel | 3276A32 | 00000 | |

| 21/32" to 3/4" | 7" | 2 3/4" | 0.001" | Steel | 3276A33 | 00000 | |

| 3/4" to 7/8" | 7" | 3 1/4" | 0.001" | Steel | 3276A34 | 00000 | |

| 7/8" to 1" | 7" | 3 1/2" | 0.001" | Steel | 3276A35 | 00000 | |

| 1" to 1 1/4" | 9" | 4" | 0.001" | Steel | 3276A38 | 000000 | |

| 1 1/4" to 1 1/2" | 9" | 4" | 0.001" | Steel | 3276A39 | 000000 | |

| 1 1/2" to 2" | 11 1/2" | 5" | 0.001" | Steel | 3276A42 | 000000 | |

| 2" to 2 3/4" | 14" | 6" | 0.001" | Steel | 3276A43 | 000000 | |

| 2 3/4" to 3 3/4" | 17" | 7" | 0.001" | Steel | 3276A44 | 000000 |

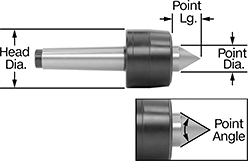

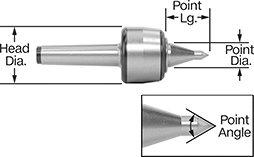

Live Centers

|  |

Standard Point | Bull-Nose Point |

|  |

Extended Point Precision | Extended-Cone Point |

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Point Dia. | Head Dia. | Point Lg. | Overall Lg. | Point Angle | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lathe Centers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 1 | 220 | 5,000 | 0.0003" | 0.59" | 1 1/2" | 45/64" | 4 1/16" | 60° | Hardened Steel | 3229A31 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 460 | 5,000 | 0.0003" | 0.7" | 1 9/16" | 7/8" | 4 47/64" | 60° | Hardened Steel | 3229A32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 925 | 4,000 | 0.0003" | 0.98" | 2 13/64" | 1 1/8" | 6 9/64" | 60° | Hardened Steel | 3229A33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,850 | 3,000 | 0.0003" | 1.1" | 2 33/64" | 1 15/64" | 7 15/64" | 60° | Hardened Steel | 3229A34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,400 | 2,500 | 0.0003" | 1.61" | 3 11/32" | 1 49/64" | 9 21/64" | 60° | Hardened Steel | 3229A35 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 7,700 | 2,000 | 0.0004" | 2.48" | 5 1/8" | 2 33/64" | 13 1/8" | 60° | Hardened Steel | 9435N11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 7 | 20,900 | 1,000 | 0.0004" | 2.95" | 5 29/32" | 2 57/64" | 17 19/32" | 60° | Hardened Steel | 9435N12 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 725 | 6,000 | 0.00005" | 0.875" | 1 3/4" | 1 1/64" | 5 19/64" | 60° | Hardened Steel | 3259A17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 970 | 5,000 | 0.00005" | 1" | 2 11/32" | 1 15/64" | 6 13/32" | 60° | Hardened Steel | 3259A12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,720 | 4,500 | 0.00005" | 1.25" | 2 11/16" | 1 31/64" | 7 57/64" | 60° | Hardened Steel | 3259A28 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3,260 | 3,500 | 0.00005" | 1.5" | 3 29/64" | 1 27/32" | 10 13/64" | 60° | Hardened Steel | 3259A29 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 4,080 | 3,500 | 0.00005" | 2" | 4" | 2 5/16" | 13 13/64" | 60° | Hardened Steel | 9435N21 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bull-Nose Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lathe Centers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 2,000 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 6 27/32" | 60° | Hardened Steel | 3265A21 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 3,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 7 15/32" | 60° | Hardened Steel | 3265A22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,760 | 3,000 | 0.0001" | 4.921" | — | 2 1/4" | 7 9/32" | 80° | Hardened Steel | 9435N27 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 4,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 8 11/32" | 60° | Hardened Steel | 3265A23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3,520 | 2,000 | 0.0001" | 5.906" | — | 2 3/4" | 8 29/32" | 80° | Hardened Steel | 9435N28 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,800 | 2,500 | 0.00015" | 4" | — | 3 29/32" | 9 15/32" | 60° | Hardened Steel | 3265A24 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High Speed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 2,700 | 7,000 | 0.0001" | 3.5" | — | 2 5/32" | 6 31/32" | 60° | Hardened Steel | 9435N13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 4,000 | 6,000 | 0.0001" | 4.5" | — | 3 1/64" | 9 7/16" | 60° | Hardened Steel | 9435N14 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 4,000 | 6,000 | 0.0001" | 4.5" | — | 3 1/64" | 10 37/64" | 60° | Hardened Steel | 9435N15 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 375 | 6,000 | 0.00005" | 0.88" | 1 3/4" | 1 11/32" | 5 5/8" | 60° | Hardened Steel | 3305A31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 740 | 5,000 | 0.00005" | 1" | 2 21/64" | 1 55/64" | 7 3/64" | 60° | Hardened Steel | 3305A32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,120 | 4,500 | 0.00005" | 1.25" | 2 11/16" | 2 3/16" | 8 19/32" | 60° | Hardened Steel | 3305A33 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1,930 | 3,500 | 0.00005" | 1.5" | 3 29/64" | 2 37/64" | 10 61/64" | 60° | Hardened Steel | 3305A34 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2,420 | 3,500 | 0.00005" | 2" | 4" | 3" | 13 29/32" | 60° | Hardened Steel | 9435N26 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended-Cone Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multipurpose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 330 | 5,000 | 0.0001" | 2.25" | — | 2 17/64" | 5 3/4" | 60° | Hardened Steel | 9435N16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 685 | 4,000 | 0.0001" | 2.63" | — | 2 21/32" | 6 15/16" | 60° | Hardened Steel | 9435N17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1,160 | 3,500 | 0.0001" | 3.5" | — | 3 31/64" | 8 11/16" | 60° | Hardened Steel | 9435N18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1,160 | 3,500 | 0.0001" | 3.5" | — | 3 31/64" | 9 51/64" | 60° | Hardened Steel | 9435N19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

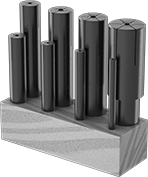

Expanding-End Lathe Mandrel Sets

No. of Pieces | Includes | End Expansion | Material | Each | ||

|---|---|---|---|---|---|---|

| 8 | Five Hex Keys One 1 1/4" OD × 1" Shank Dia × 4" Lg. Expanding-End Mandrel One 1" OD × 1" Shank Dia × 4" Lg. Expanding-End Mandrel One 1/2" OD × 1/2" Shank Dia × 3" Lg. Expanding-End Mandrel One 1/4" OD × 1/4" Shank Dia × 3" Lg. Expanding-End Mandrel One 3/4" OD × 3/4" Shank Dia × 4" Lg. Expanding-End Mandrel One 3/8" OD × 3/8" Shank Dia × 3" Lg. Expanding-End Mandrel One 5/8" OD × 5/8" Shank Dia × 3" Lg. Expanding-End Mandrel One 7/8" OD × 7/8" Shank Dia × 4" Lg. Expanding-End Mandrel Stand | 0.002" | Steel | 2779A19 | 0000000 |

Machine-Your-Own Inside-Grip 5C Lathe Collets

Head Dia. | Head Thk. | Min. Machined Dia. | Total Indicated Runout (TIR) Accuracy | Body Dia. | Overall Lg. | External Thread Size | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Machine-Your-Own Inside Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1" | 0.25" | 0.0005" | 1 1/4" | 4 1/2" | 1.234"-20 | Steel | 3242A11 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 0.437" | 0.0005" | 1 1/4" | 4 1/2" | 1.234"-20 | Steel | 3242A14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2" | 0.437" | 0.0005" | 1 1/4" | 5 1/2" | 1.234"-20 | Steel | 3242A15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 0.75" | 0.0005" | 1 1/4" | 4 1/2" | 1.234"-20 | Steel | 3242A17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 0.75" | 0.0005" | 1 1/4" | 5" | 1.234"-20 | Steel | 3242A18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 0.75" | 0.0005" | 1 1/4" | 4 1/2" | 1.234"-20 | Steel | 3242A23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1 1/2" | 0.75" | 0.0005" | 1 1/4" | 5" | 1.234"-20 | Steel | 3242A24 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 2 1/2" | 0.75" | 0.0005" | 1 1/4" | 6" | 1.234"-20 | Steel | 3242A32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

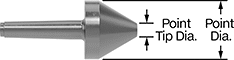

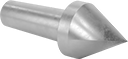

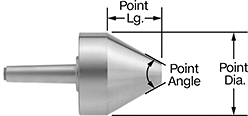

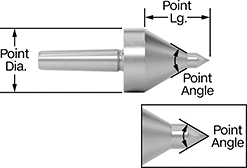

Dead Centers

Steel | Carbide-Tipped Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Machine Taper No. | Point Dia. | Point Tip Dia. | Point Lg. | Overall Lg. | Total Indicated Runout (TIR) Accuracy | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 1 | 0.475" | — | 1 3/16" | 3 5/16" | 0.00005" | 3266A2 | 0000000 | 31755A31 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.7" | — | 1 5/8" | 4 3/16" | 0.00005" | 9450N11 | 000000 | 9450N12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.938" | — | 2 1/16" | 5 1/4" | 0.00005" | 9450N13 | 000000 | 9450N14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.231" | — | 2 11/16" | 6 3/4" | 0.00005" | 9450N15 | 000000 | 9450N16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.748" | — | 3 5/16" | 8 1/2" | 0.00005" | 9450N17 | 000000 | 9450N18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.494" | — | 4 1/4" | 11 1/2" | 0.00005" | 9450N19 | 000000 | 9450N22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 7 | 3.27" | — | 5" | 15" | 0.00005" | 9450N21 | 000000 | 9450N23 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bull-Nose Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 2.13" | 1/2" | 2 13/32" | 5" | 0.00005" | 9450N24 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 2.75" | 1" | 2 33/64" | 5 3/4" | 0.00005" | 9450N25 | 000000 | 9450N26 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.75" | 1" | 2 33/64" | 6 9/16" | 0.00005" | 9450N27 | 000000 | 9450N28 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3.5" | 1" | 3 11/64" | 8 3/8" | 0.00005" | 9450N29 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Interchangeable Point Lathe Centers

Center Points

For Machine Taper No. | Point Dia. | Point Tip Dia. | Point Lg. | Point Angle | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Standard Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1" | 1/2" | 1 3/8" | — | Carbide-Tipped Steel | 9448N53 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1" | 1/2" | 1 3/8" | — | Carbide-Tipped Steel | 9448N58 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.25" | 5/8" | 1 11/16" | — | Carbide-Tipped Steel | 9448N64 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.59" | — | 3/4" | — | Steel | 9448N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.79" | — | 63/64" | — | Steel | 9448N18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.98" | — | 1 3/16" | — | Steel | 9448N26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.26" | — | 1 15/32" | — | Steel | 9448N34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 1.42" | — | 1 47/64" | — | Steel | 9448N42 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1" | — | 1 11/64" | — | Steel | 9448N49 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.13" | — | 1 19/64" | — | Steel | 9448N55 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.5" | — | 1 21/32" | — | Steel | 9448N61 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bull-Nose Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.59" | 3/64" | 19/32" | 60° | Steel | 9448N16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.87" | 1/8" | 19/32" | 90° | Steel | 9448N12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 1.46" | 23/32" | 19/32" | 90° | Steel | 9448N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.79" | 3/64" | 7/8" | 60° | Steel | 9448N24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.42" | 15/64" | 7/8" | 90° | Steel | 9448N19 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 2.48" | 1 19/64" | 7/8" | 90° | Steel | 9448N21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.98" | 3/32" | 63/64" | 60° | Steel | 9448N32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.77" | 25/64" | 63/64" | 90° | Steel | 9448N27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.76" | 1 3/8" | 63/64" | 90° | Steel | 9448N28 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.26" | 3/32" | 1 3/16" | 60° | Steel | 9448N39 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.2" | 35/64" | 1 3/16" | 90° | Steel | 9448N35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 3.15" | 1 1/2" | 1 3/16" | 90° | Steel | 9448N36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 1.42" | 5/32" | 1 27/64" | 60° | Steel | 9448N47 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.76" | 23/32" | 1 27/64" | 90° | Steel | 9448N43 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 3.94" | 1 31/32" | 1 27/64" | 90° | Steel | 9448N44 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1.75" | 7/8" | 1 11/64" | 60° | Steel | 9448N52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.25" | 1" | 1 35/64" | 60° | Steel | 9448N59 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.75" | 1 1/2" | 1 37/64" | 60° | Steel | 9448N65 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cup Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.87" | 23/32" | 19/32" | — | Steel | 9448N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 1.18" | 63/64" | 9/16" | — | Steel | 9448N15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.42" | 1 7/64" | 7/8" | — | Steel | 9448N22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1.77" | 1 1/2" | 7/8" | — | Steel | 9448N23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.77" | 1 15/32" | 63/64" | — | Steel | 9448N29 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 2.48" | 2 3/32" | 63/64" | — | Steel | 9448N31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.2" | 1 47/64" | 1 3/16" | — | Steel | 9448N37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 2.76" | 2 23/64" | 1 3/16" | — | Steel | 9448N38 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.76" | 2 9/32" | 1 27/64" | — | Steel | 9448N45 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 3.94" | 2 15/32" | 1 27/64" | — | Steel | 9448N46 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 1.13" | 7/8" | 1 5/64" | — | Steel | 9448N5 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.38" | 1 1/8" | 1 7/32" | — | Steel | 9448N56 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.5" | 1 1/4" | 1 7/32" | — | Steel | 9448N62 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flat-Knurled Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2 | 0.71" | — | 19/32" | — | Steel | 9448N17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 0.98" | — | 7/8" | — | Steel | 9448N25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.26" | — | 63/64" | — | Steel | 9448N33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.77" | — | 1 3/16" | — | Steel | 9448N41 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 6 | 2.2" | — | 1 27/64" | — | Steel | 9448N48 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Half Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 3 | 1" | 1/4" | 2" | — | Steel | 9448N54 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 1.13" | 1/4" | 2 35/64" | — | Steel | 9448N6 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.5" | 3/8" | 3 1/16" | — | Steel | 9448N66 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended-Tip Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live and Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 2, Morse 3 | 0.75" | 3/8" | 1 19/64" | — | Steel | 9448N51 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 4 | 0.8" | 1/2" | 1 51/64" | — | Steel | 9448N57 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Morse 5 | 1.2" | 1/2" | 2 1/8" | — | Steel | 9448N63 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

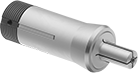

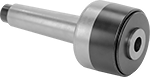

Center Bodies

|  |  |

Dead | Live | Precision Live |

Lathe Centers | Extractors | Hex Nuts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Overall Lg. | Material | Includes | Each | Each | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dead | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.00025" | 3/4" | 4 3/8" | Steel | — | 9445N18 | 0000000 | 9452N26 | 000000 | 25 | 90494A237 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.00025" | 1" | 5 1/2" | Steel | — | 9445N21 | 000000 | 9452N26 | 00000 | 10 | 90494A239 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 0.00025" | 1 1/4" | 6 13/16" | Steel | — | 9445N23 | 000000 | 9452N27 | 00000 | 1 | 90496A061 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 220 | 5,000 | 0.0008" | 1 37/64" | 4 3/64" | Steel | — | 9445N11 | 000000 | 9452N16 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 440 | 4,000 | 0.0008" | 2 13/64" | 5 7/32" | Steel | — | 9445N12 | 000000 | 9452N17 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 880 | 3,000 | 0.0008" | 2 33/64" | 6 7/32" | Steel | — | 9445N13 | 000000 | 9452N18 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,770 | 2,500 | 0.0012" | 3 23/64" | 7 13/16" | Steel | — | 9445N14 | 000000 | 9452N19 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3,550 | 2,000 | 0.0012" | 5 1/8" | 10 27/32" | Steel | — | 9445N15 | 000000 | 9452N21 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Live | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 5,000 | 0.00025" | 2 1/8" | 4 15/16" | Steel | 1" dia. Hardened Steel Standard Point | 9445N16 | 000000 | 9452N26 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 5,000 | 0.00025" | 2 1/8" | 5 9/16" | Steel | 1" dia. Hardened Steel Standard Point | 9445N17 | 000000 | 9452N26 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 550 | 5,000 | 0.00025" | 3 5/64" | 7 13/64" | Steel | 1.13" dia. Hardened Steel Standard Point | 9445N19 | 000000 | 9452N26 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,400 | 5,000 | 0.00025" | 3 5/64" | 8 21/64" | Steel | 1.5" dia. Hardened Steel Standard Point | 9445N22 | 00000000 | 9452N27 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Interchangeable Point Lathe Center Sets

Dead Lathe Center

Machine Taper No. | Total Indicated Runout (TIR) Accuracy | Head Dia. | Thread Size | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse 3 | 0.00025" | 3/4" | 7/8"-14 | 3 3/16" | 4 3/8" | Steel | 7 | 0.75" dia. Hardened Steel Extended-Tip Point, 1" dia. Carbide-Tipped Hardened Steel Standard Point, 1" dia. Hardened Steel Half Point, 1" dia. Hardened Steel Standard Point, 1.75" dia. Hardened Steel Bull-Nose Point, Dead Center Body, Point Extractor | 9438N11 | 000000000 | |

| Morse 4 | 0.00025" | 1" | 1 1/8"-12 | 4 1/16" | 5 1/2" | Steel | 7 | 0.8" dia. Hardened Steel Extended-Tip Point, 1" dia. Carbide-Tipped Hardened Steel Standard Point, 1.13" dia. Hardened Steel Half Point, 1.13" dia. Hardened Steel Standard Point, 2.25" dia. Hardened Steel Bull-Nose Point, Dead Center Body, Point Extractor | 9438N12 | 00000000 | |

| Morse 5 | 0.00025" | 1 1/4" | 1 5/8"-12 | 5 3/16" | 6 13/16" | Steel | 7 | 1.2" dia. Hardened Steel Extended-Tip Point, 1.25" dia. Carbide-Tipped Hardened Steel Standard Point, 1.5" dia. Hardened Steel Half Point, 1.5" dia. Hardened Steel Standard Point, 2.75" dia Hardened Steel Bull-Nose Point, Dead Center Body, Point Extractor | 9438N13 | 00000000 |

Precision, Live Lathe Center

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse 2 | 100 | 5,000 | 0.00025" | 2 1/8" | 2 9/16" | 4 15/16" | Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point, 1" dia. Hardened Steel Standard Point, 1.13" dia. Hardened Steel Cup Point, 1.75" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N22 | 0000000 | |

| Morse 3 | 350 | 5,000 | 0.00025" | 2 1/8" | 3 3/16" | 5 9/16" | Steel | 6 | 0.75" dia. Hardened Steel Extended-Tip Point, 1" dia. Hardened Steel Standard Point, 1.13" dia. Hardened Steel Cup Point, 1.75" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N23 | 00000000 | |

| Morse 4 | 550 | 5,500 | 0.00025" | 3 5/64" | 4 1/16" | 7 13/64" | Steel | 6 | 0.8" dia. Hardened Steel Extended-Tip Point, 1.13" dia. Hardened Steel Standard Point, 1.38" dia. Hardened Steel Cup Point, 2.25" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N24 | 00000000 | |

| Morse 5 | 1,400 | 5,500 | 0.00025" | 3 5/64" | 5 3/16" | 8 21/64" | Steel | 6 | 1.2" dia. Hardened Steel Extended-Tip Point, 1.5" dia. Hardened Steel Cup Point, 1.5" dia. Hardened Steel Standard Point, 2.75" dia Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N25 | 00000000 |

Live Lathe Center

Machine Taper No. | Max. Workpiece Cap., lb. | Max. Rotation Speed, rpm | Total Indicated Runout (TIR) Accuracy | Head Dia. | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse 2 | 220 | 5,000 | 0.0008" | 1 37/64" | 2 33/64" | 4 3/64" | Steel | 9 | 0.59" dia. Hardened Steel Bull-Nose Point, 0.59" dia. Hardened Steel Standard Point, 0.71" dia. Hardened Steel Flat-Knurled Point, 0.87" dia. Hardened Steel Bull-Nose Point, 0.87" dia. Hardened Steel Cup Point, 1.18" dia. Hardened Steel Cup Point, 1.46" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N11 | 0000000 | |

| Morse 3 | 440 | 4,000 | 0.0008" | 2 13/64" | 3 3/16" | 5 7/32" | Steel | 9 | 0.79" dia. Hardened Steel Bull-Nose Point, 0.79" dia. Hardened Steel Standard Point, 0.98" dia. Hardened Steel Flat-Knurled Point, 1.42" dia. Hardened Steel Bull-Nose Point, 1.42" dia. Hardened Steel Cup Point, 1.77" dia. Hardened Steel Cup Point, 2.48" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N12 | 000000 | |

| Morse 4 | 880 | 3,000 | 0.0008" | 2 33/64" | 4 1/32" | 6 7/32" | Steel | 8 | 0.98" dia. Hardened Steel Standard Point, 1.26" dia. Hardened Steel Flat-Knurled Point, 1.77" dia. Hardened Steel Bull-Nose Point, 1.77" dia. Hardened Steel Cup Point, 2.48" dia. Hardened Steel Cup Point, 2.76" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N13 | 000000 | |

| Morse 5 | 1,770 | 2,500 | 0.0012" | 3 23/64" | 5 3/32" | 7 13/16" | Steel | 8 | 1.26" dia. Hardened Steel Bull-Nose Point, 1.26" dia. Hardened Steel Standard Point, 1.77" dia. Hardened Steel Flat-Knurled Point, 2.2" dia. Hardened Steel Bull-Nose Point, 2.2" dia. Hardened Steel Cup Point, 3.15" dia. Hardened Steel Bull-Nose Point, Live Center Body, Point Extractor | 9452N14 | 000000 | |

| Morse 6 | 3,550 | 2,000 | 0.0012" | 5 1/8" | 7 9/64" | 10 27/32" | Steel | 9 | 1.42" dia. Hardened Steel Bull-Nose Point, 1.42" dia. Hardened Steel Standard Point, 2.2" dia. Hardened Steel Flat-Knurled Point, 2.76" dia. Hardened Steel Bull-Nose Point, 2.76" dia. Hardened Steel Cup Point, 3.94" dia. Hardened Steel Bull-Nose Point, 3.94" dia. Hardened Steel Cup Point, Live Center Body, Point Extractor | 9452N15 | 00000000 |