About Shafts

More

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use. 12L14 carbon steel shafts have a lead additive that makes them easier to machine than any other rotary shaft but also more prone to wear.

Some steel shafts have a finish or coating to add corrosion or wear resistance. A black oxide finish gives the shaft mild corrosion resistance, so it should be used in dry environments. A chrome plating gives the shaft wear resistance and makes it more corrosion resistant than a shaft with a black oxide finish.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Finish Hardness Rating | Finish Hardness | Each | |

Inch—1566 Carbon Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

7/8" Dia. (Tolerance: -0.003" to 0") | |||||||||

| 12" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 000000 |

| 18" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 00000 |

| 24" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 00000 |

| 36" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 00000 |

| 60" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 000000 |

| 72" | -0.0313" to 0.0313" | 0.012" per ft. | Chamfered | Hard | Rockwell C25 | __ | __ | 00000000 | 000000 |

Inch—12L14 Carbon Steel | |||||||||

7/8" Dia. (Tolerance: -0.0004" to 0") | |||||||||

| 12" | -0.01" to 0.01" | 0.0096" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 00000 |

| 18" | -0.01" to 0.01" | 0.0096" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 00000 |

| 24" | -0.01" to 0.01" | 0.0096" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 000000 |

| 36" | -0.01" to 0.01" | 0.0096" per ft. | Chamfered | Medium | Brinell 167 | __ | __ | 00000000 | 000000 |

Inch—Black-Oxide 1045 Carbon Steel | |||||||||

7/8" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

| 18" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

| 24" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

| 36" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

| 48" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

| 60" | -0.0625" to 0.0625" | 0.0125" per ft. | Chamfered | Hard | Rockwell C20 | Medium | Rockwell C19 | 0000000 | 00000 |

Inch—Chrome-Plated 1045 Carbon Steel | |||||||||

7/8" Dia. (Tolerance: -0.001" to 0") | |||||||||

| 12" | 0" to 0.125" | 0.0125" per ft. | Straight | Medium | Brinell 203 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 18" | 0" to 0.125" | 0.0125" per ft. | Straight | Medium | Brinell 203 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 24" | 0" to 0.125" | 0.0125" per ft. | Straight | Medium | Brinell 203 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 36" | 0" to 0.125" | 0.0125" per ft. | Straight | Medium | Brinell 203 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

| 48" | 0" to 0.125" | 0.0125" per ft. | Straight | Medium | Brinell 203 | Ultra Hard | Rockwell C68 | 0000000 | 00000 |

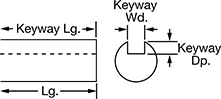

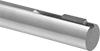

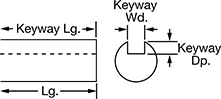

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. 1045 carbon steel shafts balance high strength and good machinability, making them ideal for general purpose use.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | ||||||||||

7/8" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 3" | 3" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 000000 |

| 6" | 6" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 00000 |

| 9" | 9" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 00000 |

| 12" | 12" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 00000 |

| 18" | 18" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 00000000 | 00000 |

| 24" | 24" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 0000000 | 00000 |

| 36" | 36" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 0000000 | 00000 |

| 48" | 48" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 0000000 | 00000 |

| 60" | 60" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 0000000 | 00000 |

| 72" | 72" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B95 | 0000000 | 000000 |

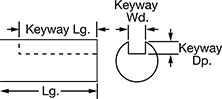

Partially Keyed Rotary Shafts

These shafts have keyways only on the ends, leaving a plain shaft in the center. The keyways work with the included ANSI machine keys to transmit torque to gears, sprockets, and other keyed components. Use the middle of the shaft with bearings and other round-bore components. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to meet tight diameter and straightness tolerances.

1045 carbon steel shafts are stronger than 303 stainless steel shafts. They have excellent machinability, so you can easily cut your own lengths.

| Lg. | Keyway Lgs. | ANSI Keys Included | Dia. Tolerance | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

7/8" Dia. (Keyway: 3/16" Wd. × 3/32" Dp.) | ||||||||||

| 24" | 4", 14" | One 2" Long Key, One 4" Long Key | -0.002" to 0" | 0" to 0.125" | 0.003" per ft. | Chamfered | Medium | Brinell 190 | 00000000 | 000000 |

| 36" | 4", 14" | One 2" Long Key, One 4" Long Key | -0.002" to 0" | 0" to 0.125" | 0.003" per ft. | Chamfered | Medium | Brinell 190 | 00000000 | 00000 |

| 48" | 4", 14" | One 2" Long Key, One 4" Long Key | -0.002" to 0" | 0" to 0.125" | 0.003" per ft. | Chamfered | Medium | Brinell 190 | 00000000 | 000000 |

| 60" | 4", 14" | One 2" Long Key, One 4" Long Key | -0.002" to 0" | 0" to 0.125" | 0.003" per ft. | Chamfered | Medium | Brinell 190 | 00000000 | 000000 |

| 72" | 4", 14" | One 2" Long Key, One 4" Long Key | -0.002" to 0" | 0" to 0.125" | 0.003" per ft. | Chamfered | Medium | Brinell 190 | 00000000 | 000000 |

Keyed Rotary Shafts with Material Certification

In addition to diameter tolerances that are twice as tight as standard keyed shafts, these shafts include a traceable lot number and test report. Use them with machine keys (not included) to transmit torque to gears, sprockets, and other power transmission components. Shafts are 1045 carbon steel, a general purpose shafting material that balances high strength and good machinability. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to meet tight diameter and straightness tolerances.

Keyway | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—1045 Carbon Steel | |||||||||||

7/8" Dia. (Tolerance: -0.001" to 0") | |||||||||||

| 3" | -0.005" to 0.005" | 3" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 000000 |

| 6" | -0.005" to 0.005" | 6" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 00000 |

| 9" | -0.005" to 0.005" | 9" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 00000 |

| 12" | -0.005" to 0.005" | 12" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 00000 |

| 24" | -0.005" to 0.005" | 24" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 00000 |

| 36" | -0.005" to 0.005" | 36" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 000000 |

| 48" | -0.005" to 0.005" | 48" | 0.188" | 0.094" | No | 0.003" per ft. | Chamfered | Medium | Rockwell C14 | 0000000 | 000000 |

Splined Rotary Shafts

Good for hydraulic systems, machine tools, and other high-torque applications, these shafts have teeth that transmit high rotational loads. Compared to keyed shafts, they last longer and handle higher torque. They’re also better than keyed shafts for applications requiring frequent disassembly or adjustments because you can move bushings along their splines.

Involute splines have curved teeth, similar to the teeth on a gear. These teeth make more contact with a bushing than the teeth on parallel splines, so these splines are less prone to wear. They handle misalignment and reduce vibration.

Bushings act as a surface to transmit rotary motion or to position a load along the length of the shaft. If welded into place, these bushings can act as a coupler, connecting two splined shafts.