Hard Wear-Resistant 52100 Alloy Steel Balls

- Yield Strength: 295,000 psi

- Hardness: Rockwell C60 (Very Hard)

- Fabrication: Cold Worked

- Specifications Met: See table

High carbon and chromium content makes this 52100 alloy steel extremely hard and resistant to wear. It’s also known as chrome steel. Often used as bearings, these balls are hardened for increased abrasion and impact resistance.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Heat Treatment | Pkg. Qty. | Pkg. | |

Mirror-Like | |||||

|---|---|---|---|---|---|

| 19/32" | -0.0001" to 0.0001" | Hardened | 25 | 0000000 | 000000 |

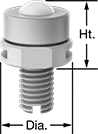

Stud-Mount Ball Transfers

Install these ball transfers in a threaded hole or use a nut to secure.

Stainless steel balls offer the most corrosion resistance. Ball transfers with an angled working orientation can be used to form support stands.

Capacity is given for the ball up orientation. Using these ball transfers in a ball down or angled orientation could reduce the capacity stated.

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Thread Size | Stud Lg. | Each | ||

Stainless Steel Ball | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Aluminum Housing | |||||||||

| L | 5/16" | 55 | 1/2" | 19/32" | Ball Up, Ball Down, Angle | M4 | 5/16" | 0000000 | 000000 |

Clean Room Stud-Mount Ball Transfers

Unlike most ball transfers, which have metal balls, these have a plastic outer ball that rolls on stainless steel inner balls, so there's no metal-on-metal contact that could create and release particles into your clean room. They've also been ultrasonically cleaned and then individually bagged to prevent dust contamination. These ball transfers were originally developed for the electronics manufacturing industry, where aligning glass layers in monitors and screens must be done without introducing dust. Use them to create conveyors, transfer tables, and material staging areas in your clean room.

PEEK ball transfers withstand more wear and are more chemical resistant than acetal ball transfers, so they handle more demanding applications.

Vespel® polyimide ball transfers are nonconductive, which means they prevent stray electrical charges from passing between your material and equipment. They're best for moving glass and other material with a polished surface because they're smoother than acetal and PEEK ball transfers and won't scratch surfaces.

Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Dia. | Cap., lbs. | Ht. | Dia. | Working Orientation | Housing Color | Size | Pitch, mm | Stud Lg. | Temperature Range, °F | Environmental Rating | Each | |

PEEK Plastic Ball | ||||||||||||

PEEK Plastic/Stainless Steel Housing | ||||||||||||

| 3/8" | 2 1/2 | 9/16" | 19/32" | Ball Up | Beige | M8 | 1.25 | 15/32" | 0° to 260° | Fed. Std. Class 1,000 | 0000000 | 000000 |

Vespel® Polyimide Plastic Ball | ||||||||||||

Vespel® Polyimide Plastic/Stainless Steel Housing | ||||||||||||

| 3/8" | 1 | 9/16" | 19/32" | Ball Up | Brown | M8 | 1.25 | 15/32" | 0° to 200° | Fed. Std. Class 1,000 | 0000000 | 000000 |