Tow Hooks

Add an anchor point to pull stuck vehicles out of mud, snow, or ditches. Mount these hooks to a bumper or trailer and then attach a tow strap or chain. The maximum trailer weight is the total weight being towed.

Double hooks bolt to both sides of a vehicle for balanced towing. You can also use only one of the hooks to tow, but someone must counter-steer in the towed vehicle to keep it in a straight line.

Powder-coated steel hooks offer more corrosion resistance than uncoated steel in wet environments.

Note: Capacity is reduced 25% in off-road use.

Overall | Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Trailer Wt., lbs. | Dp. | Ht. | Material | Hook Opening Wd. | No. of | Dia. | Ctr.-to-Ctr. | Mounting Plate Thick. | Each | |

Single Hook | ||||||||||

| 10,000 | 3 1/4" | 5" | Powder-Coated Steel | 1 5/8" | 2 | 1/2" | 1 3/8" | 1" | 000000 | 00000 |

| 20,000 | 4 7/8" | 5 3/8" | Powder-Coated Steel | 2 1/8" | 3 | 1/2" | 2 13/16" 2 1/2" | 1" | 0000000 | 00000 |

| 30,000 | 5 1/4" | 6" | Powder-Coated Steel | 2 1/8" | 4 | 1/2" | 2 3/4" 2 1/4" | 3/4" | 0000000 | 00000 |

Double Hooks | ||||||||||

| 13,500 | 5 1/4" | 8 1/2" | Powder-Coated Steel | 2 3/16" | 2 | 3/4" | 4 1/4" | 1 1/2" | 0000000 | 00000 |

| 44,000 | 5 7/16" | 9 1/4" | Steel | 2 1/2" | 1 1 | 3/4" 5/8" | 4 3/16" | 1 7/16" | 0000000 | 000000 |

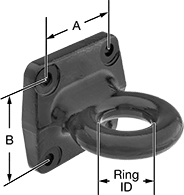

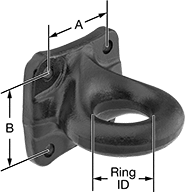

Drawbar Rings

These rings mount to a trailer and connect to the drawbar coupler or tow hook on a vehicle to create a towing connection. Maximum trailer weight is the total weight being towed. Vertical capacity (also known as tongue weight) represents the weight of the load on the drawbar ring.

Note: Capacity is reduced 25% in off-road use.

Overall | Ring | Mounting Hole | Mounting Plate | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | For Max. Trailer Wt., lbs. | Vertical Capacity, lbs. | Dp. | Ht. | Material | ID | Thick. | Dia. | Ctr.-to-Ctr. (A) | Ctr.-to-Ctr. (B) | Wd. | Ht. | Each | |

Bolt On | ||||||||||||||

| 1 | 42,000 | 7,000 | 6 11/16" | 6" | Steel | 2 1/2" | 1 1/4" | 5/8" | 4 1/2" | 4 1/2" | 6" | 6" | 00000000 | 0000000 |

| 2 | 60,000 | 15,000 | 6 13/16" | 6 3/8" | Steel | 3" | 1 5/8" | 3/4" | 4 1/2" | 4 1/2" | 6 5/8" | 6 3/8" | 00000000 | 000000 |

| 2 | 100,000 | 20,000 | 6 13/16" | 6 3/8" | Steel | 3" | 1 5/8" | 7/8" | 4 1/2" | 4 1/2" | 6 5/8" | 6 3/8" | 00000000 | 000000 |

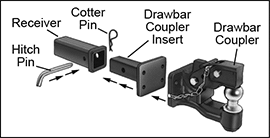

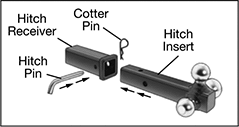

Hitch Receivers

Mount these receivers to a vehicle. Use them with an insert and pin to create a complete hitch for towing. Maximum trailer weight is the total weight being towed. Vertical capacity (also known as tongue weight) represents the weight of the load on the drawbar ring or hitch ball.

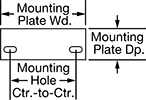

Mounting Plate | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Max. Trailer Wt., lbs. | Vertical Capacity, lbs. | Hitch Receiver Size | Material | Color | Mounting Hole Center-to-Center | Wd. | Dp. | Each | |

| 5,000 | 500 | 2" Square | Powder-Coated Steel | Black | 8 1/2" | 12" | 4 1/2" | 0000000 | 000000 |