Filter by

System of Measurement

For Housing ID

Inner Ring Type

For Load Direction

Cage Material

Bearing Construction

Plain Bearing Type

RoHS

Maximum Rotation Speed

Shaft Type

REACH

Ball Material

Dynamic Radial Load Capacity

DFARS Specialty Metals

Ball Bearings

|

Shielded |

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2.5 | 5 | 35 | 100,000 | -40 | 240 | Standard | 52-2Z | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Ball Bearings

Flange, mm | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | OD | Thk. | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 1.5 | 6.1 | 0.5 | 3 | 30 | 110,000 | -50 | 300 | Standard | 682 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2 | 6.2 | 0.6 | 3 | 30 | 110,000 | -50 | 300 | Standard | 52 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2.5 | 6.2 | 0.6 | 3 | 30 | 94,000 | -50 | 300 | Standard | 52-2Z | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2.3 | 6.1 | 0.6 | 3 | 30 | 94,000 | -50 | 300 | Standard | 682-2Z | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2.5 | 6.2 | 0.6 | 3 | 30 | 94,000 | -50 | 300 | Standard | 52-2Z | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

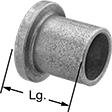

Oil-Embedded Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 5 | 3 | 13 lb. @ 120 rpm | Synthetic Oil | -35 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 2 | 12 lb. @ 120 rpm | Mineral Oil | 10 to 220 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 18 lb. @ 120 rpm | Synthetic Oil | -35 to 300 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5 | 4 | 37 lb. @ 120 rpm | Mineral Oil | 10 to 220 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 37 lb. @ 120 rpm | Synthetic Oil | -15 to 300 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Precision Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Min. | Max. | Inner Ring Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 1.5 | 7 | 22 | 100,000 | -30 | 280 | Standard | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Dynamic Radial Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 18 lb. @ 120 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Load 863 Iron Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 5 | 3 | 27 lb. @ 120 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 37 lb. @ 120 rpm | Synthetic Oil | PTFE | -60 to 300 | — | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction Oil-Embedded Flanged Sleeve Bearings

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Lubricant Additive | Temp. Range, ° F | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 5 | 3 | 6.5 | 1.8 | 13 lb. @ 120 rpm | 95 lb. @ 120 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 6.5 | 1.8 | 18 lb. @ 120 rpm | 90 lb. @ 120 rpm | Synthetic Oil | PTFE | -60 to 300 | ASTM B438 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Flanged Sleeve Bearings

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 5 | 3 | 6.5 | 1.8 | 13 lb. @ 120 rpm | 95 lb. @ 120 rpm | Synthetic Oil | -35 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 6.5 | 1.8 | 18 lb. @ 120 rpm | 90 lb. @ 120 rpm | Synthetic Oil | -35 to 300 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Embedded Flanged Sleeve Bearings for Food and Beverage

|

For Shaft Dia., mm | For Housing ID, mm | Lg., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Dynamic Thrust Load Cap. @ Speed | Base Oil | Temp. Range, ° F | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

841 Bearing Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 5 | 3 | 6.5 | 1.8 | 18 lb. @ 120 rpm | 90 lb. @ 120 rpm | Synthetic Oil | -75 to 300 | FDA Compliant 21 CFR 178.3570 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||