About Plain Bearings

More

Light Duty Dry-Running Thrust Bearings

Use where high loads and speeds are not required.

Thermoplastic bearings are fiber reinforced and lubricant infused for good wear resistance and low friction with light and medium loads.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If your application’s load and speed requirements are below the values listed, the bearing will work.

| OD | Thick. | Dynamic Thrust Load Capacity | Color | Temp. Range, °F | Each | |

Thermoplastic Blend Bearings | ||||||

|---|---|---|---|---|---|---|

For 32 mm Shaft Dia. | ||||||

| 54mm | 1.5mm | 245 lbs. @ 30 rpm | Gray | -40° to 260° | 0000000 | 00000 |

Metric Press-Fit Drill Bushings

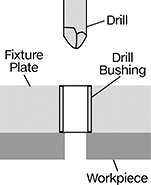

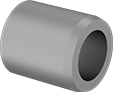

Also known as jig bushings, these metric drill bushings fit inside fixture plate holes to precisely guide drill bits, counterbores, reamers, and other cutting tools. They improve accuracy so that your drilled holes and cuts are consistent from part to part. Known for their versatility, drill bushings are also used as spacers, shims, and machinery bushings. These bushings are made of hardened, ground steel that holds its shape and resists wear, so they last for many cycles without needing to be replaced.

All bushings have a chamfer on the outside that centers the bushing as you place it into the hole. Press into place with a manual or hydraulic press. Since the bushing is sized slightly larger than the hole for an extremely tight fit, it’ll stay put permanently. These are ANSI Type PM bushings—also known as headless bushings—which means you don’t need to counterbore the hole to mount them flush.

They also have an internal chamfer that makes it easy to insert bits, pins, and punches without damaging the bushing or misaligning tools. DIN 179 bushings meet dimensional and material standards that make sure they're compatible with other parts and tools. Although DIN 179 is no longer an active standard, it's still a common reference point for designers.

Don't see the size you need? Additional sizes are available.

Tolerance | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | Internal Chamfer | For Drill Bit Size | For Drill Bit Size Decimal Equivalent | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

32 mm ID | |||||||||||||||

| 48 | 25 | One End | 32 mm | 1.2598" | 0.025 to 0.05 | 0.017 to 0.033 | -0.2 to 0.2 | PM | Steel | Rockwell C61 | DIN 179 | 000000000 | 000000 | 000000 | 000000 |

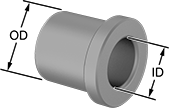

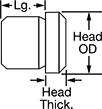

Metric Press-Fit Drill Bushings with Head

Even under extreme drilling pressure, these metric bushings won't press through your jig plate. They’re ANSI Type H bushings, also known as headed bushings. A flanged head acts as a stop, so these bushings won’t move as you push down your drill bit, reamer, or other cutting bit. Use them even in jigs made of thin or soft materials—the head adds support to protect your jig from damage caused by heavy use. Drill bushings ensure accurate, consistent cuts and drilled holes from one part to the next. They’re also used as spacers, shims, and machinery bushings. Made of hardened, ground steel, these bushings hold their shape and resist wear, so they last for many cycles without needing to be replaced.

These bushings meet DIN 172 dimensional standards. This standard is no longer active, but it’s often used as a reference point for making sure parts are compatible with other parts and tools.

To install, fit the bushing into a hole in your jig. In a standard hole, the head will sit above the jig plate; to mount flush, install in a countersunk hole. A chamfered edge on the bottom of the bushing helps center the bushing in the hole. Once it’s centered, press the bushing into the hole with a hydraulic or lever press.

Head | Tolerance | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Lg., mm | For Drill Bit Size | For Drill Bit Size Decimal Equivalent | OD, mm | Thick., mm | ID, mm | OD, mm | Lg., mm | Drill Bushing Type | Material | Hardness | Specifications Met | 1-5 | 6-11 | 12-Up | |

32 mm ID | ||||||||||||||||

| 48 | 20 | 32 mm | 1.2598" | 52 | 5 | 0.025 to 0.05 | 0.017 to 0.033 | -0.2 to 0.2 | H | Steel | Rockwell C61 | DIN 172 | 000000000 | 000000 | 000000 | 000000 |

Flush-Mount Screw-Clamp Bushings

Insert these bushings into the bore of your sprocket for flush or recessed mounting. They handle shock loads. When you tighten the included clamping screws, the bushing's inner sleeve contracts onto the shaft and the outer sleeve expands to hold your sprocket, pulley, or gear. They can be mounted on shafts with or without keyways.

| For Shaft Dia. | OD | Overall Wd. | Max. Torque, in.-lbs. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

| 32mm | 60mm | 54mm | 10,350 | 142 | Steel | Clamping Screws | 0000000 | 0000000 |

Taper-Lock Bushings

Mount these hubless bushings flush into your sprocket or pulley for a slim profile with no protruding screws. They are for use with taper-lock sprockets of the same bushing style. As you tighten the included set screws, the bushing grips the shaft and pulls it into your sprocket or pulley.

Keyway | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

1210 Style Bushing | |||||||||

| 32mm | 25mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 000000 |

1610 Style Bushing | |||||||||

| 32mm | 25mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

1615 Style Bushing | |||||||||

| 32mm | 38mm | 10mm | 3.3mm | 8° | 175 | Steel | Set Screws | 000000000 | 00000 |

2012 Style Bushing | |||||||||

| 32mm | 32mm | 10mm | 3.3mm | 8° | 280 | Steel | Set Screws | 000000000 | 00000 |

2517 Style Bushing | |||||||||

| 32mm | 44mm | 10mm | 3.3mm | 8° | 430 | Steel | Set Screws | 000000000 | 00000 |

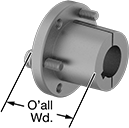

Quick-Disconnect (QD) Bushings

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect (QD) sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

Keyway | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Fastener Tightening Torque, in.-lbs. | Material | Includes | Each | |

Clamp On | ||||||||

SD Style Bushing | ||||||||

| 32mm | 46mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 000000 |

SDS Style Bushing | ||||||||

| 32mm | 35mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 00000 |

SH Style Bushing | ||||||||

| 32mm | 33mm | 10mm | 3.3mm | 108 | Steel | Clamping Screws | 0000000 | 00000 |

SK Style Bushing | ||||||||

| 32mm | 49mm | 10mm | 3.3mm | 180 | Steel | Clamping Screws | 0000000 | 00000 |

Split-Tapered Bushings

The tapered barrel on these bushings is split on both sides, allowing them to contract more tightly around the shaft than quick-disconnect and taper-lock bushings. They're for use with split-tapered sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

Bushings with a machine key fit into a matching keyway on a sprocket or pulley for high-torque applications.

Keyway | |||||||

|---|---|---|---|---|---|---|---|

| For Shaft Dia. | Overall Wd. | Wd. | Dp. | Taper | Fastener Tightening Torque, in.-lbs. | Each | |

Steel | |||||||

H Style Bushing with Machine Key | |||||||

| 32mm | 1 1/4" | 8mm | 3mm | 3° | 95 | 00000000 | 000000 |