Filter by

System of Measurement

OD

Screw Size

Shoulder Diameter

Material

Bearing Type

Plain Bearing Type

Shape

Performance

REACH

RoHS

DFARS Specialty Metals

Export Control Classification Number (ECCN)

For Load Direction

Minimum Hardness

Hardness

Shaft Mount Type

Color

For Use With

Sold As

Magnetic Properties

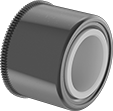

Dry-Running Panel-Mount Sleeve Bearings

|

For Shaft Dia., mm | OD, mm | Wd., mm | Flange OD, mm | Flange Thk., mm | Dynamic Radial Load Cap. @ Speed | Misalignment Capability | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Acetal Bearing with Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Press-Fit Panel Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 12.73 | 9.6 | 14.2 | 0.8 | 36 lb. @ 120 rpm | 5° | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Low-Friction PTFE-Filled Acetal Bearing with Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Press-Fit Panel Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 12.73 | 9.6 | 14.3 | 0.8 | 80 lb. @ 120 rpm | 5° | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

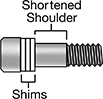

Shims for Shortening Screw Shoulders

Thk. | Thk. Tolerance | For Screw Size | ID, mm | ID Tolerance, mm | OD, mm | OD Tolerance, mm | Min. Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 8 mm Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.01" | -0.001" to 0.001" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" | -0.0015" to 0.0015" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.025" | -0.0015" to 0.0015" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.031" | -0.002" to 0.002" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.062" | -0.002" to 0.002" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Highly Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 8 mm Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.01" | -0.001" to 0.001" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.031" | -0.003" to 0.003" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell B70 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stress-Resistant Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 8 mm Diameter Shoulder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.005" | -0.0005" to 0.0005" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.01" | -0.001" to 0.001" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" | -0.002" to 0.002" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.031" | -0.003" to 0.003" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.06" | -0.004" to 0.004" | M8 | 8 | 0 to 0.25 | 12.73 | -0.25 to 0 | Rockwell C40 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||