How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

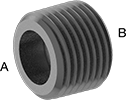

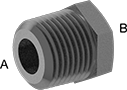

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: See table

- Specifications Met: ASME B16.14

- Pipe Nipples and Pipe: Use Schedule 40 steel

Pipe Size | |||||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male × NPT Female | |||||||

| 1/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 00000 |

| 3/8 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/8 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1/2 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1/2 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1/2 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/4 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/4 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 3/4 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | 000000000 | 0000 |

| 1 1/4 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 1 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 1/2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 1/2 | 2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | 2 | 125 | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | 2 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | 3 | 125 | 150 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

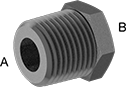

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Specifications Met: See table

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Male × NPT Female | ||||||||

| 1/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 00000 |

| 3/8 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 0000 |

| 3/8 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 0000 |

| 1/2 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 0000 |

| 1/2 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 0000 |

| 1/2 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | __ | 000000000 | 0000 |

| 3/4 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 3/4 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 3/4 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 3/4 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 | 1/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 1/4 | 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | __ | 000000000 | 00000 |

| 1 1/4 | 3/8 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | __ | 000000000 | 0000 |

| 1 1/4 | 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 0000 |

| 1 1/4 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 0000 |

| 1 1/4 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 1/2 | 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 1 1/2 | 3/8 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 1 1/2 | 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 1 1/2 | 3/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 00000 |

| 1 1/2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 00000 |

| 1 1/2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 0000 |

| 2 | 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 | 3/8 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 | 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 | 3/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 | 1 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 00000 |

| 2 | 1 1/4 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Steel | ASME B16.14 | 000000000 | 00000 |

| 2 | 1 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 3/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 1 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 1 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 1 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 2 1/2 | 2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 3/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 1 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 1 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 1 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 | 2 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 1 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 1 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 1 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 2 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 3 1/2 | 3 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 1 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 1 1/4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 1 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 2 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 3 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 4 | 3 1/2 | 150 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 00000 |

| 6 | 2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 000000 |

| 6 | 2 1/2 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 000000 |

| 6 | 3 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 000000 |

| 6 | 4 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 000000 |

| 6 | 5 | 125 | 175 psi @ 72° F | 125 psi @ 350° F | Iron | ASME B16.14 | 000000000 | 000000 |

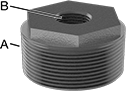

- For Use With: Air, Diesel Fuel, Gasoline, Oil, Steam, Water

- Pipe Nipples and Pipe: Use Schedule 40 steel

Pipe Size | ||||||

|---|---|---|---|---|---|---|

| (A) | (B) | Lg. | Hex Wd. | Material | Each | |

NPT Male × NPT Female | ||||||

| 1 1/2 | 1/2 | 1 7/32" | 1 13/32" | Iron | 0000000 | 000000 |

| 1 1/2 | 3/4 | 1 5/16" | 1 23/32" | Iron | 0000000 | 00000 |

| 1 1/2 | 1 | 1 5/16" | 2" | Iron | 0000000 | 00000 |

| 2 | 3/8 | 1 5/16" | 1 25/64" | Iron | 0000000 | 00000 |

| 2 | 1/2 | 1 5/16" | 1 25/64" | Iron | 0000000 | 00000 |

| 2 | 3/4 | 1 3/8" | 1 21/32" | Iron | 0000000 | 00000 |

| 2 | 1 | 1 11/16" | 2 1/32" | Iron | 0000000 | 00000 |

| 2 | 1 1/4 | 1 9/16" | 2 21/32" | Iron | 0000000 | 00000 |

| 2 | 1 1/2 | 1 25/32" | 2 33/64" | Iron | 0000000 | 00000 |

| 2 1/2 | 2 | 1 25/32" | 3" | Iron | 0000000 | 00000 |

| 3 | 1 | 1 9/16" | 2 5/16" | Iron | 0000000 | 000000 |

| 3 | 1 1/2 | 1 21/32" | 2 45/64" | Iron | 0000000 | 00000 |

| 3 | 2 | 1 3/4" | 3 1/4" | Iron | 0000000 | 00000 |

| 4 | 1 | 1 7/8" | 2 7/8" | Iron | 0000000 | 00000 |

| 4 | 2 | 1 13/32" | 3 3/8" | Iron | 0000000 | 00000 |

| 4 | 2 1/2 | 2 11/32" | 4 21/64" | Iron | 0000000 | 000000 |

| 4 | 3 | 2 7/16" | 4 3/4" | Iron | 0000000 | 00000 |

FM-Approved Low-Pressure Cast Iron Threaded Pipe Fittings

Suitable for use in fire-protection applications, these pipe fittings are made of cast iron, so they are brittle and can be quickly opened with the strike of a sledge hammer. They are also known as Pressure Class 125 fittings. Use in noncorrosive environments.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.14

- Pipe Nipples and Pipe: Use Schedule 40 steel

Pipe Size | ||||||

|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male × NPT Female | ||||||

| 1 1/4 | 3/8 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | 1/2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/4 | 3/4 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/2 | 3/8 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | 1/2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/2 | 3/4 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/2 | 1 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 2 | 1/2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 3/4 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 1 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | 1 1/4 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 1/2 | 1 1/2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | 2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | 2 1/2 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | 3 | 125 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.4

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | ||||||

|---|---|---|---|---|---|---|

| 1 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

| 1 1/4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.4

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | ||||||

|---|---|---|---|---|---|---|

| 1 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 2 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

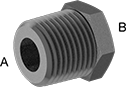

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Phosphate-coated and zinc-phosphate-coated fittings offer some corrosion resistance, but aren't intended for corrosive environments.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A105, ASME B16.11, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

Pipe Size | Dash Size | |||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male × NPT Female | ||||||||

| 1/4 | 1/8 | 04 | 02 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3/8 | 1/8 | 06 | 02 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 3/8 | 1/4 | 06 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1/2 | 1/8 | 08 | 02 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1/2 | 1/4 | 08 | 04 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1/2 | 3/8 | 08 | 06 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 3/4 | 1/8 | 12 | 02 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 3/4 | 1/4 | 12 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 3/4 | 3/8 | 12 | 06 | 3,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 3/4 | 1/2 | 12 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 | 1/8 | 16 | 02 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 | 1/4 | 16 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 | 3/8 | 16 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 | 1/2 | 16 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 | 3/4 | 16 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 1/8 | 20 | 02 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 1/4 | 20 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 3/8 | 20 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 1/2 | 20 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 3/4 | 20 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/4 | 1 | 20 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/2 | 1/8 | 24 | 02 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 1 1/2 | 1/4 | 24 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 1 1/2 | 3/8 | 24 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/2 | 1/2 | 24 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/2 | 3/4 | 24 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/2 | 1 | 24 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 1 1/2 | 1 1/4 | 24 | 20 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 0000 |

| 2 | 1/4 | 32 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 3/8 | 32 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 1/2 | 32 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 3/4 | 32 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 1 | 32 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 1 1/4 | 32 | 20 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 | 1 1/2 | 32 | 24 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 1/4 | 40 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 3/8 | 40 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 1/2 | 40 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 3/4 | 40 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 1 | 40 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 1 1/4 | 40 | 20 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 1 1/2 | 40 | 24 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 2 1/2 | 2 | 40 | 32 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 1/4 | 48 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 1/2 | 48 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 3/4 | 48 | 12 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 1 | 48 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 1 1/4 | 48 | 20 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 1 1/2 | 48 | 24 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 2 | 48 | 32 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 3 | 2 1/2 | 48 | 40 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

| 4 | 1/4 | 64 | 04 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 3/8 | 64 | 06 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 1/2 | 64 | 08 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 1 | 64 | 16 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 1 1/4 | 64 | 20 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 1 1/2 | 64 | 24 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 2 | 64 | 32 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 2 1/2 | 64 | 40 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |

| 4 | 3 | 64 | 48 | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 000000 |