Filter by

For Use With

System of Measurement

Priming Type

Flow Rate

Maximum Flow Rate

Container Size

Duty Cycle

Maximum Pressure

Pump Style

Runs Dry

Intake Connection

Diaphragm Material

Maximum Temperature

DFARS Specialty Metals

Continuous-Duty Any-Direction Constant-Flow-Rate Diaphragm Pumps for Water and Coolants

Intake | Discharge | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Flow Rate, gpm | Flow Rate @ Pressure | Max. Pressure, psi | Max. Viscosity, cP | Max. Temp., ° F | Power, hp | Current, amp | Connection | Gender | For Tube ID | Connection | Gender | For Tube ID | Lg. | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase—With Thermal Overload Protection and With Pressure Switch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 2.50 gpm @ 20 psi | 40 | 250 | 130 | 3/16 | 1.8 | Barbed | Male | 1/2" | Barbed | Male | 1/2" | 10 7/8" | 5 3/8" | 5 5/8" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed-Flow-Rate Peristaltic Pumps for Chemicals

Pumps | Replacement Pump Heads | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gal./day (For Tube ID) | Max. Pressure, psi | Max. Viscosity, cP | Temp., ° F | Power | Current, amp | Lg. | Wd. | Ht. | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

115V AC, Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF and Viton® Fluoroelastomer Wetted Parts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02 (1/32") 0.07 (1/16") 0.25 (1/8") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 0000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11 (1/32") 0.34 (1/16") 1.25 (1/8") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 4 1/2" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/32" ID Viton® Fluoroelastomer Tubing (Shore A60), 4 1/2" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.87 (1/16") 3.53 (1/8") 6.84 (3/16") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.75 (1/16") 7.07 (1/8") 13.68 (3/16") | 30 | 800 | 32 to 122 | Fractional | 0.03 | 5 1/2" | 3 1/4" | 3 3/4" | 6" Lg. of 1/16" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 1/8" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22.8 (3/16") 38 (1/4") | 15 | 500 | 32 to 122 | Fractional | 0.52 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 45.6 (3/16") 76 (1/4") | 15 | 200 | 32 to 122 | Fractional | 0.65 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 228 (3/16") 380 (1/4") | 15 | 50 | 32 to 122 | Fractional | 1.74 | 5" | 5" | 7" | 6" Lg. of 1/4" ID Viton® Fluoroelastomer Tubing (Shore A60), 6" Lg. of 3/16" ID Viton® Fluoroelastomer Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC/240V AC, Single Phase—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Norprene and Santoprene Wetted Parts | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 (1/8") 12 (3/16") 20 (1/4") | 25 | 5,000 | 33 to 104 | Not Rated | 2 | 5 5/8" | 6 1/4" | 5 3/4" | 9" Lg. of 1/4" ID Norprene Tubing (Shore A60), 9" Lg. of 1/8" ID Norprene Tubing (Shore A60), 9" Lg. of 3/16" ID Norprene Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 (1/8") 56 (3/16") 91 (1/4") | 25 | 5,000 | 33 to 104 | Not Rated | 2 | 5 5/8" | 6 1/4" | 5 3/4" | 9" Lg. of 1/4" ID Norprene Tubing (Shore A60), 9" Lg. of 1/8" ID Norprene Tubing (Shore A60), 9" Lg. of 3/16" ID Norprene Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 (1/8") 88 (3/16") 144 (1/4") | 25 | 5,000 | 33 to 104 | Not Rated | 2 | 5 5/8" | 6 1/4" | 5 3/4" | 9" Lg. of 1/4" ID Norprene Tubing (Shore A60), 9" Lg. of 1/8" ID Norprene Tubing (Shore A60), 9" Lg. of 3/16" ID Norprene Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 77 (1/8") 162 (3/16") 265 (1/4") | 25 | 5,000 | 33 to 104 | Not Rated | 2 | 5 5/8" | 6 1/4" | 5 3/4" | 9" Lg. of 1/4" ID Norprene Tubing (Shore A60), 9" Lg. of 1/8" ID Norprene Tubing (Shore A60), 9" Lg. of 3/16" ID Norprene Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 122 (1/8") 257 (3/16") 421 (1/4") | 25 | 5,000 | 33 to 104 | Not Rated | 2 | 5 5/8" | 6 1/4" | 5 3/4" | 9" Lg. of 1/4" ID Norprene Tubing (Shore A60), 9" Lg. of 1/8" ID Norprene Tubing (Shore A60), 9" Lg. of 3/16" ID Norprene Tubing (Shore A60) | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Air-Powered Double Diaphragm Pumps for Harsh Chemicals

Threaded Side Intake and Threaded Side Discharge

Double Diaphragm Pumps | Air Motor Pump Repair Kits | Fluid Side Pump Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Max. Flow Rate, gpm | Max. Solids Dia. | Air Consumption, ft³/min | Air Connection Size | Intake Size | Discharge Size | Lg. | Wd. | Ht. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

231 ft. Maximum Feet of Head—100 psi Maximum Discharge Pressure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | 0.06" | 4.8 | 1/8 Female NPT | 1/4 Female NPT | 1/4 Female NPT | 3 3/8" | 5 1/2" | 6 1/2" | 000000 | 000000000 | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.7 | 0.08" | 9.3 | 1/8 Female NPT | 3/8 Female NPT | 3/8 Female NPT | 3 1/2" | 5 7/8" | 7 5/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 0.16" | 29 | 1/4 Female NPT | 1/2 Female NPT | 1/2 Female NPT | 6" | 9 3/16" | 8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 39 | 0.24" | 46 | 1/4 Female NPT | 1 Female NPT | 1 Female NPT | 8" | 10 7/8" | 10 3/8" | 000000 | 00000000 | 0000000 | 000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Panel-Mount Fixed-Flow-Rate Peristaltic Pumps for Chemicals

Discharge | Overall | Blue Housing | Clear Housing | Green Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, ml/min | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | Power, hp | Current, amp | Intake Connection | Tube ID | Tube OD | Connection | Wd. | Ht. | Dp. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24V DC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardwire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 25 | 10,000 | 32 to 100 | 1/150 | 1.5 | Barbed | 3/16" | 5/16" | Barbed | 2 1/2" | 2 1/2" | 4 1/8" | 00000000 | 0000000 | 00000000 | 0000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 160 | 25 | 10,000 | 32 to 100 | 1/150 | 1.5 | Barbed | 3/16" | 5/16" | Barbed | 2 1/2" | 2 1/2" | 4 1/8" | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Compact Drum Pumps for Water and Chemicals

Temp., ° F | Intake | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Flow Rate, fl oz/stroke | For Container Size, gal. | Max. Viscosity | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Spout Type | Drum Pump Type | Each | |||

| A | 2, 4, 6, 8 | 5 | Not Rated | Not Rated | 125 | 3/4 NPT | — | 5/8" | 18 1/4" | Spout End | Fixed | Plunger | 0000000 | 000000 | ||

| A | 2, 4, 6, 8 | 15 to 55 | Not Rated | Not Rated | 125 | 3/4 NPT, 2 NPT | Two Drum Connectors | 5/8" | 33" | Spout End | Fixed | Plunger | 0000000 | 00000 | ||

| A | 4, 8, 12, 16 | 15 to 55 | Not Rated | Not Rated | 125 | 3/4 NPT, 2 NPT | Two Drum Connectors | 5/8" | 33" | Spout End | Fixed | Plunger | 0000000 | 00000 | ||

| B | 3 | 55 | Not Rated | 40 | 150 | 2 NPT | Drum Connector | 1 3/4" | 32" | Spout End | Flexible | Plunger | 0000000 | 000000 | ||

Nondrip Drum Pumps for Fuel and Flammable Liquid

Temp., ° F | Intake | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | For Drum Opening Size | Includes | Tube OD | Tube Lg. | Discharge Location | Drum Pump Type | Nozzle Type | Features | Flammability Rating | Each | |||

| 4.5 | 2 to 55 | 270 | 35 | 110 | 2 NPT | Drum Connector | 5/8" | 40" | Nozzle | Plunger | Nondrip | Bonding and Grounding Wires | NFPA 30 18.4.4.1 | 0000000 | 0000000 | ||

Drum Pumps for Harsh Chemicals

Peristaltic Pumps for Chemicals

Pumps | Replacement Pump Collars | Replacement Pump Intake Tubes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gal/day | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | Power, hp | Current, amp | ID | OD | Intake Connection | Discharge Connection | Lg. | Wd. | Ht. | Includes | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 12 | 25 | 200 | 35 to 100 | 1/64 | 0.3 | 3/16" | 3/8" | Compression | Compression | 8" | 7" | 6" | 9" Lg. of Tygon Tubing (Shore A70) | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 to 20 | 25 | 200 | 35 to 100 | 1/64 | 0.3 | 1/4" | 7/16" | Compression | Compression | 8" | 7" | 6" | 9" Lg. of Tygon Tubing (Shore A70) | 00000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Peristaltic Pumps for Chemicals

Pumps | Replacement Pump Heads | Replacement Tubing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Discharge | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gal/day | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, ° F | Power, hp | Current, amp | Intake Connection | Tube ID | Tube OD | Connection | Lg. | Wd. | Ht. | Includes | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.3 to 5 | 100 | 1,500 | 35 to 125 | 1/30 | 1.7 | Compression | 3/16" | 1/4" | Compression | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 to 17 | 100 | 1,500 | 35 to 125 | 1/30 | 1.7 | Compression | 3/16" | 1/4" | Compression | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 to 40 | 100 | 1,500 | 35 to 125 | 1/30 | 1.7 | Compression | 3/16" | 1/4" | Compression | 11" | 5" | 6" | 20-ft. Lg. of LDPE Plastic Intake/Discharge Tubing | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inline Water-Powered Metering Syringe Pumps for Chemicals

Intake | Discharge | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Max. Pressure, psi | Max. Viscosity, cP | Concentration Ratio | Max. Temp., ° F | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Dia. | Ht. | Includes | Each | |||

| 0.05 to 14 | 85 | 200 | 1:500 to 1:50 | 100 | 3/4 | NPT | Male | 3/4 | NPT | Male | 6 5/16" | 19" | 6-ft. PVC Plastic Intake Tube | 0000000 | 0000000 | ||

| 0.05 to 14 | 85 | 200 | 1:3000 to 1:333 | 100 | 3/4 | NPT | Male | 3/4 | NPT | Male | 6 5/16" | 21" | 6-ft. PVC Plastic Intake Tube | 0000000 | 00000000 | ||

| 0.05 to 14 | 85 | 1,700 | 1:100 to 1:10 | 100 | 3/4 | NPT | Male | 3/4 | NPT | Male | 6 5/16" | 19" | 6-ft. PVC Plastic Intake Tube | 0000000 | 00000000 | ||

| 0.05 to 14 | 85 | 1,700 | 1:200 to 1:20 | 100 | 3/4 | NPT | Male | 3/4 | NPT | Male | 6 5/16" | 19" | 6-ft. PVC Plastic Intake Tube | 0000000 | 00000000 | ||

PVDF Long-Life Air-Powered Drum Pumps for Chemicals

Drum Pumps | Pump Repair Kits | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Connection | Pipe Size | Tube Lg. | Discharge Location | Connection | Pipe Size | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE Diaphragm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | 55 | 3,000 | 40 | 210 | 100 | 12 | 2 NPT | Drum Connector | 1/4 Female NPT | Threaded | 1/2 Female NPT | 36" | Pump Body | Threaded | 1/2 Female NPT | 0000000 | 000000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Drum Pump Systems for Water, Oil, Coolants, and Chemicals

Temp. | Intake | Discharge | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Discharge Pressure, psi | For Container Size, gal. | Max. Viscosity, cP | Min. | Max., ° F | Power, hp | Current, amp | For Drum Opening Size | Tube OD | Tube Lg. | Tube ID | Tube OD | Tube Lg. | Enclosure Rating | Connection | No. of Blades | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Single Phase—NEMA 5-15 Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVDF Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 39" | 1" | 1 1/4" | 72" | IP54 | Straight Blade | 3 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 15 | 55 | 1,500 | Not Rated | 175 | 1 | 7.5 | 2 NPT | 1 5/8" | 47" | 1" | 1 1/4" | 72" | IP54 | Straight Blade | 3 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

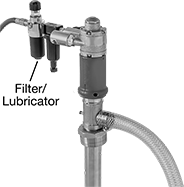

Air-Powered Drum Pumps with Hose and Filter/Lubricator for Water, Oil, Coolants, and Chemicals

Drum Pumps | Pump Repair Kits | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Temp., ° F | Intake | Discharge | ||||||||||||||||||||

Flow Rate, gpm | For Container Size, gal. | Max. Viscosity, cP | Min. | Max. | Air Pressure, psi | Air Consumption, ft³/min | For Drum Opening Size | Includes | Air Connection | Tube OD | Tube Lg. | Discharge Location | Tube ID | Tube Lg., ft. | Tube Material | Features | Each | Each | ||||

| 16 | 55 | 2,000 | 35 | 150 | 80 to 100 | 32 | 2 NPT | Drum Connector | 1/4 Female NPT | 1 5/8" | 40" | Tube End | 1" | 5 | PVC | 15-ft. Air Hose Assembly, Air Filter/Lubricator, Ball Valve, Muffler | 0000000 | 000000000 | 0000000 | 0000000 | ||