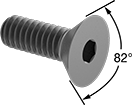

About Flat Head Screws

More

About Rounded Head Screws

More

About Socket Head Screws

More

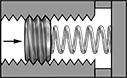

About Set Screws

More

Alloy Steel Socket Head Screws

With a tensile strength of 170,000 psi, these alloy steel screws are stronger than Grade 8 steel screws. Length is measured from under the head.

Black-oxide steel screws are mildly corrosion resistant in dry environments. Fine and extra-fine threads are closely spaced to prevent loosening from vibration; the finer the thread, the better the resistance. They are not compatible with coarse threads.

Screws that meet ASTM A574, ASTM A574M, and ISO 898-1 comply with specifications and testing requirements for material quality.

Head | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Threading | Min. Thread Lg. | Thread Spacing | Dia. | Ht. | Drive Size | Tensile Strength, psi | Specifications Met | Pkg. Qty. | Pkg. | |

5-44 | |||||||||||

Black-Oxide Alloy Steel | |||||||||||

| 1/4" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 170,000 | ASTM A574 | 10 | 000000000 | 000000 |

| 3/8" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 170,000 | ASTM A574 | 10 | 000000000 | 00000 |

| 1/2" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 170,000 | ASTM A574 | 10 | 000000000 | 00000 |

| 3/4" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 170,000 | ASTM A574 | 10 | 000000000 | 00000 |

| 1" | Partially Threaded | 3/4" | Fine | 0.205" | 1/8" | 3/32" | 170,000 | ASTM A574 | 5 | 000000000 | 0000 |

18-8 Stainless Steel Socket Head Screws

Made from 18-8 stainless steel, these screws have good chemical resistance and may be mildly magnetic. Length is measured from under the head. Fine threads are closely spaced to prevent loosening from vibration. They are not compatible with coarse threads.

Screws that meet ASME B1.1, ASME B18.3, ISO 21269, and ISO 4762 (formerly DIN 912) comply with standards for dimensions.

Head | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Threading | Min. Thread Lg. | Thread Spacing | Dia. | Ht. | Drive Size | Tensile Strength, psi | Specifications Met | Pkg. Qty. | Pkg. | |

5-44 | |||||||||||

18-8 Stainless Steel | |||||||||||

| 1/4" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 70,000 | ASME B18.3 | 50 | 000000000 | 00000 |

| 3/8" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 70,000 | ASME B18.3 | 100 | 000000000 | 0000 |

| 1/2" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 70,000 | ASME B18.3 | 50 | 000000000 | 0000 |

| 3/4" | Fully Threaded | __ | Fine | 0.205" | 1/8" | 3/32" | 70,000 | ASME B18.3 | 50 | 000000000 | 0000 |

| 1" | Partially Threaded | 3/4" | Fine | 0.205" | 1/8" | 3/32" | 70,000 | ASME B18.3 | 50 | 000000000 | 0000 |

Super-Corrosion-Resistant 316 Stainless Steel Socket Head Screws

More corrosion resistant than 18-8 stainless steel screws, these screws have excellent resistance to chemicals and salt water. They may be mildly magnetic. Length is measured from under the head.

Fine threads are closely spaced to prevent loosening from vibration. They are not compatible with coarse threads.

Head | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Threading | Thread Spacing | Dia. | Ht. | Drive Size | Finish | Tensile Strength, psi | Pkg. Qty. | Pkg. | |

316 Stainless Steel | ||||||||||

5-44 | ||||||||||

| 1/4" | Fully Threaded | Fine | 0.205" | 1/8" | 3/32" | Passivated | 70,000 | 50 | 000000000 | 00000 |

| 3/8" | Fully Threaded | Fine | 0.205" | 1/8" | 3/32" | Passivated | 70,000 | 50 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Fine | 0.205" | 1/8" | 3/32" | Passivated | 70,000 | 50 | 000000000 | 0000 |

18-8 Stainless Steel Button Head Hex Drive Screws

18-8 stainless steel button head screws have good chemical resistance and may be mildly magnetic. Length is measured from under the head.

Alloy Steel Button Head Hex Drive Screws

Made from alloy steel, these screws are nearly twice as strong as stainless steel button head screws. Length is measured from under the head.

Black-oxide alloy steel screws are mildly corrosion resistant in dry environments.

| Lg. | Threading | Head Dia. | Head Ht. | Drive Size | Tensile Strength, psi | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

5-44 | |||||||||

| 1/4" | Fully Threaded | 0.238" | 0.066" | 5/64" | 120,000 | ASME B18.3;ASTM F835 | 10 | 000000000 | 000000 |

| 3/8" | Fully Threaded | 0.238" | 0.066" | 5/64" | 120,000 | ASME B18.3;ASTM F835 | 10 | 000000000 | 00000 |

| 1/2" | Fully Threaded | 0.238" | 0.066" | 5/64" | 120,000 | ASME B18.3;ASTM F835 | 10 | 000000000 | 00000 |

Alloy Steel Hex Drive Flat Head Screws

Made from alloy steel, these screws are nearly twice as strong as stainless steel flat head screws. They're angled under the head to sit flush within countersunk holes. Length is measured from the top of the head.

Black-oxide alloy steel screws have mild corrosion resistance in dry environments.

| Lg. | Threading | Flat Head Profile | Head Dia. | Head Ht. | Drive Size | Tensile Strength, psi | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

5-44 | ||||||||||

| 3/8" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | 130,000 | ASTM F835 | 10 | 000000000 | 00000 |

| 1/2" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | 130,000 | ASTM F835 | 10 | 000000000 | 00000 |

| 3/4" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | 130,000 | ASTM F835 | 10 | 000000000 | 00000 |

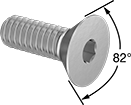

18-8 Stainless Steel Hex Drive Flat Head Screws

These 18-8 stainless steel screws have good chemical resistance and may be mildly magnetic. They’re angled under the head to sit flush within countersunk holes. Length is measured from the top of the head.

Passivated stainless steel screws have added protection against oxidation and corrosion.

| Lg. | Threading | Flat Head Profile | Head Dia. | Head Ht. | Drive Size | Finish | Tensile Strength, psi | Specifications Met | Pkg. Qty. | Pkg. | |

18-8 Stainless Steel—82° Countersink Angle | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

5-44 | |||||||||||

| 1/4" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | Passivated | 70,000 | ASME B18.3 | 10 | 000000000 | 00000 |

| 3/8" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | Passivated | 70,000 | ASME B18.3 | 10 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Standard | 0.281" | 0.09" | 5/64" | Passivated | 70,000 | ASME B18.3 | 10 | 000000000 | 0000 |

Alloy Steel Cup-Point Set Screws

Made from alloy steel, these set screws have a thin edge that digs into hard surfaces for a secure hold. Length listed is the overall length.

Black-oxide alloy steel set screws resist corrosion in dry environments.

| Lg. | Drive Size | Hardness | Specifications Met | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | ||||||

|---|---|---|---|---|---|---|

5-44 | ||||||

| 1/8" | 1/16" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 000000 |

| 3/16" | 1/16" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 00000 |

| 1/4" | 1/16" | Rockwell C45 | ASME B18.3, ASTM F912 | 100 | 000000000 | 00000 |

| 5/16" | 1/16" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

| 3/8" | 1/16" | Rockwell C45 | ASME B18.3, ASTM F912 | 25 | 000000000 | 00000 |

Alloy Steel Hollow-Lock Set Screws

Also known as jam set screws, these lock other screws in place, hold pins, and adjust spring tension. The hollow design allows you to inspect locked parts. A black-oxide finish provides corrosion resistance in dry environments. Length listed is the overall length.

| Lg. | Drive Size | Hardness | Pkg. Qty. | Pkg. | |

Black-Oxide Alloy Steel | |||||

|---|---|---|---|---|---|

5-44 | |||||

| 3/32" | 1/16" | Rockwell C45 | 10 | 000000000 | 000000 |