Filter by

Width

Height

Length

Shape

Environment

Bottom Inside Length

Capacity

Cover Material

RoHS

Export Control Classification Number (ECCN)

Inside Height

DFARS Specialty Metals

Food Industry Standard

Food and Beverage Plastic Pans

|  |

Style D | Style E |

Style D—Polyethylene

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Autoclavable | Max. Temp., ° F | Food Industry Std. | Each | ||

| 3 | 20 3/4" | 16 1/2" | 3" | 20 1/2" | 16 1/4" | White | No | 180 | NSF/ANSI 2 | 000000 | 000000 | |

| 3 3/4 | 17 1/2" | 15 1/2" | 4" | 17 1/4" | 15 1/4" | White | No | 180 | NSF/ANSI 2 | 0000000 | 00000 | |

| 5 | 23" | 19" | 4" | 22 1/4" | 18 1/2" | White | No | 180 | NSF/ANSI 2 | 000000 | 00000 | |

| 8 | 29 1/4" | 23 1/4" | 4" | 29" | 23" | White | No | 180 | NSF/ANSI 2 | 000000 | 00000 | |

Style E—Polyethylene

Bottom Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Autoclavable | Max. Temp., ° F | Space Saving Features | Food Industry Std. | Each | ||

| 96 fl. oz. | 15" | 6 1/2" | 4" | 12 1/2" | 4 1/8" | White | No | 180 | Nestable | NSF/ANSI 2 | 000000 | 000000 | |

| 1 gal. | 15" | 8 1/2" | 4" | 12 1/4" | 5 3/4" | White | No | 180 | Nestable | NSF/ANSI 2 | 000000 | 00000 | |

| 1 3/4 gal. | 17 3/4" | 14" | 4" | 15 1/2" | 11" | White | No | 180 | Nestable | NSF/ANSI 2 | 000000 | 00000 | |

Food and Beverage Fiberglass Pans

|  |

Style C | Style D |

Style D

Bottom Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Autoclavable | Max. Temp., ° F | Space Saving Features | Food Industry Std. | Choose a Color | Each | ||

| 1 1/4 | 18 3/4" | 11 7/8" | 1 3/4" | 17" | 11" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 000000 | |

| 1 1/4 | 22" | 12" | 1 1/4" | 21 1/8" | 11 1/8" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

| 3 | 23 3/8" | 12" | 3 1/8" | 21 1/8" | 11 1/8" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

| 5 | 30 3/8" | 15 7/8" | 2 3/4" | 29 5/8" | 15 1/8" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

| 5 3/4 | 23 3/8" | 12" | 6" | 21" | 11" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

| 9 1/4 | 31 3/4" | 19 1/8" | 4 1/2" | 29 3/4" | 18" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

| 10 1/4 | 25 3/4" | 15 3/4" | 7 1/4" | 23 1/2" | 14" | Yes | 250 | Stackable | NSF/ANSI 2 | Gray , Green , White | 0000000 | 00000 | |

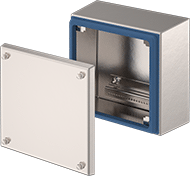

Sanitary Enclosures

Enclosures | Standoffs | Replacement Keys | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Dp. | Cover Closure Method | With Knockouts | Enclosure Rating | Food Industry Std. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 7" | 3" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 | 000000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 7" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17" | 9" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17" | 13" | 4 3/4" | Screw | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 | 000000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

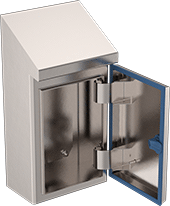

Hinged Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 1/2" | 17" | 6" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 22" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 30" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 26" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 30" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 37" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30" | 39" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 22" | 8 1/2" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 32" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 48" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 32" | 56" | 12" | Key Lock | No | NEMA 4X, NEMA 13, IP66, IP09 | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 | 000000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sanitary Push-Button Enclosures

Enclosures | Plugs | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | For 22 mm Push Buttons | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Holes | Columns | Rows | Wd. | Ht. | Dp. | Material | Cover Closure Method | Enclosure Rating | Food Industry Std. | External Mount Type | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Raised Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4" | 4" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | — | Bracket | 00000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4" | 4" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 00000000 | 000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1 | 2 | 4" | 6" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | — | Bracket | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1 | 2 | 4" | 6" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 00000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 3 | 4" | 8" | 2 3/4" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 00000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Raised Mount with Overhanging Roof | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 | 1 | 4 1/2" | 6" | 4 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 00000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 3 | 4 1/2" | 10" | 4 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP69K, IP66 | FDA Compliant 21 CFR 177.2600 | Standoff | 00000000 | 000000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recessed Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lift-Off Cover | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3 | 1 | 11" | 8 1/2" | 3 1/2" | 316L Stainless Steel | Screw | NEMA 4X, NEMA 13, IP66 | FDA Compliant 21 CFR 177.2600 | Mounting Hole | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

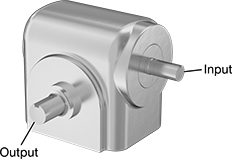

Sanitary Right-Angle Speed Reducers

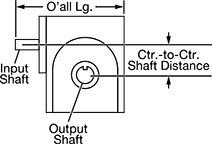

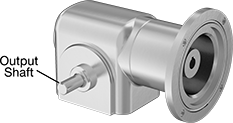

With 1 Output Shaft

|  |

Reducer with Left-Side Output | Reducer with Right-Side Output |

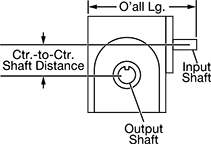

|  |

Reducer with Left-Side Output | Reducer with Right-Side Output |

Max. Output | Max. Input | Input Shaft | Output Shaft | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Torque | Speed, rpm | Speed, rpm | Power, hp | Dia. | Lg. | Dia. | Lg. | Shaft Ctr.-to-Ctr. Distance | Lg. | Wd. | Ht. | Radial Load Cap., lb. | Enclosure Rating | Choose an Output Shaft Location | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 429 in·lbf @ 1,750 rpm | 350 | 1,750 | 2.53 | 3/4" | 1.57" | 3/4" | 1.97" | 1.54" | 7.46" | 7.03" | 5.45" | 600 | IP69K | Left Side , Right Side | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 736 in·lbf @ 1,750 rpm | 350 | 1,750 | 2.96 | 3/4" | 1.57" | 1 1/8" | 2.15" | 1.97" | 7.6" | 8.09" | 6.35" | 1,200 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,240 in·lbf @ 1,750 rpm | 88 | 1,750 | 1.58 | 3/4" | 1.57" | 1 1/8" | 2.15" | 1.97" | 7.6" | 8.09" | 6.35" | 1,200 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 912 in·lbf @ 1,750 rpm | 58 | 1,750 | 1 | 3/4" | 1.57" | 1" | 1.86" | 1.75" | 7.93" | 7.13" | 5.84" | 1,100 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 643 in·lbf @ 1,750 rpm | 44 | 1,750 | 0.59 | 3/4" | 1.57" | 3/4" | 1.97" | 1.54" | 7.46" | 7.03" | 5.45" | 600 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 871 in·lbf @ 1,750 rpm | 44 | 1,750 | 0.8 | 3/4" | 1.57" | 1" | 1.86" | 1.75" | 7.93" | 7.13" | 5.84" | 1,100 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,130 in·lbf @ 1,750 rpm | 44 | 1,750 | 0.99 | 3/4" | 1.57" | 1 1/8" | 2.15" | 1.97" | 7.6" | 8.09" | 6.35" | 1,200 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 594 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.39 | 3/4" | 1.57" | 3/4" | 1.97" | 1.54" | 7.46" | 7.03" | 5.45" | 600 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 807 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.53 | 3/4" | 1.57" | 1" | 1.86" | 1.75" | 7.93" | 7.13" | 5.84" | 1,100 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,050 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.69 | 3/4" | 1.57" | 1 1/8" | 2.15" | 1.97" | 7.6" | 8.09" | 6.35" | 1,200 | IP69K | Left Side , Right Side | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

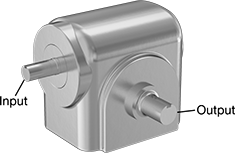

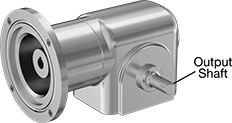

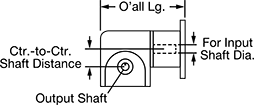

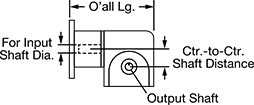

Sanitary Right-Angle Speed Reducers for Face-Mount AC Motors

With 1 Output Shaft

|  |

Reducer with Left-Side Output | Reducer with Right-Side Output |

|  |

Reducer with Left-Side Output | Reducer with Right-Side Output |

Max. Output | Max. Input | Output Shaft | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Torque | Speed, rpm | Speed, rpm | Power, hp | For Input Shaft Dia. | Dia. | Lg. | Shaft Ctr.-to-Ctr. Distance | Lg. | Wd. | Ht. | Radial Load Cap., lb. | Enclosure Rating | Choose an Output Shaft Location | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For NEMA 56C Motor Frames | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 429 in·lbf @ 1,750 rpm | 350 | 1,750 | 2.53 | 5/8" | 3/4" | 2.063" | 1.54" | 9.49" | 7.56" | 6.7" | 450 | IP69K | Left Side , Right Side | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 736 in·lbf @ 1,750 rpm | 350 | 1,750 | 2.96 | 5/8" | 1 1/8" | 2.087" | 1.97" | 10.126" | 7.94" | 7.496" | 950 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 597 in·lbf @ 1,750 rpm | 175 | 1,750 | 1.84 | 5/8" | 3/4" | 2.063" | 1.54" | 9.49" | 7.56" | 6.7" | 450 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 957 in·lbf @ 1,750 rpm | 87 | 1,750 | 1.55 | 5/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 912 in·lbf @ 1,750 rpm | 58 | 1,750 | 1 | 5/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

40:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 643 in·lbf @ 1,750 rpm | 43 | 1,750 | 0.59 | 5/8" | 3/4" | 2.063" | 1.54" | 9.49" | 7.56" | 6.7" | 450 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 840 in·lbf @ 1,750 rpm | 35 | 1,750 | 0.64 | 5/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 594 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.39 | 5/8" | 3/4" | 2.063" | 1.54" | 9.49" | 7.56" | 6.7" | 450 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 807 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.53 | 5/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,050 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.69 | 5/8" | 1 1/8" | 2.087" | 1.97" | 10.126" | 7.94" | 7.496" | 950 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For NEMA 140TC Motor Frames | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 574 in·lbf @ 1,750 rpm | 350 | 1,750 | 2.9 | 7/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

20:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 957 in·lbf @ 1,750 rpm | 87 | 1,750 | 1.55 | 7/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

50:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 840 in·lbf @ 1,750 rpm | 35 | 1,750 | 0.64 | 7/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

60:1 Speed Ratio | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 807 in·lbf @ 1,750 rpm | 29 | 1,750 | 0.53 | 7/8" | 1" | 2.063" | 1.75" | 9.49" | 7.56" | 7.06" | 750 | IP69K | Left Side , Right Side | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||