Filter by

System of Measurement

Fitting Connection

Thread Type

Shape

Flare Style

Cap Type

Certification

Fabrication

Maximum Temperature

Minimum Temperature

REACH

For Tube Fabrication

DFARS Specialty Metals

Export Control Classification Number (ECCN)

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

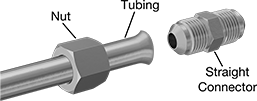

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Caps

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water;

except caps for 1/8" tube OD are only for use with refrigerant - Specifications Met: See table

For Tube | Each | |||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Specifications Met | 1-9 | 10-49 | 50-Up | |

| 1/8" | 0.03" | Brass | 2,800 psi @ 73° F | __ | 000000000 | 00000 | 00000 | 00000 |

| 3/16" | 0.03" | Brass | 1,900 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 5/16" | 0.032" | Brass | 1,200 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 1/2" | 0.032" | Brass | 750 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 5/8" | 0.035" | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 | 0000 | 0000 |

| 3/4" | 0.035" | Brass | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 | 00000 | 00000 |

Plugs

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

| 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | 000000000 | 00000 | 00000 | 00000 |

| 5/16" | 0.032" | Brass | 1,200 psi @ 72° F | 000000000 | 0000 | 0000 | 0000 |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 | 0000 | 0000 |

| 1/2" | 0.032" | Brass | 750 psi @ 72° F | 000000000 | 0000 | 0000 | 0000 |

| 5/8" | 0.035" | Brass | 650 psi @ 72° F | 000000000 | 0000 | 0000 | 0000 |

Nuts

(A) Short Nut

(B) Short Nut

(A) Long Nut

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

For Tube | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Lg. | 1-19 | 20-99 | 100-Up | ||

Short Nuts | |||||||||

| A | 1/8" | 0.03" | Brass | 2,800 psi @ 72° F | 1/2" | 000000000 | 00000 | 00000 | 00000 |

| A | 3/16" | 0.035" | Brass | 1,900 psi @ 72° F | 5/8" | 000000000 | 0000 | 0000 | 0000 |

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 3/4" | 000000000 | 0000 | 0000 | 0000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 7/8" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 29/32" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1" | 000000000 | 0000 | 0000 | 0000 |

| A | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 1" | 000000000 | 0000 | 0000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 1/8" | 000000000 | 0000 | 0000 | 0000 |

| A | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 1 1/16" | 000000000 | 0000 | 0000 | 0000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 5/16" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/4" | 0.035" | Brass | 550 psi @ 72° F | 1 5/32" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/4" | 0.109" | Brass | 550 psi @ 72° F | 1 1/2" | 000000000 | 00000 | 0000 | 0000 |

| B | 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | 5/8" | 00000000 | 0000 | 0000 | 0000 |

| B | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 27/32" | 000000000 | 0000 | 0000 | 0000 |

| B | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 31/32" | 000000000 | 0000 | 0000 | 0000 |

Long Nuts | |||||||||

| A | 1/8" | 0.03" | Brass | 2,800 psi @ 72° F | 3/4" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/16" | 0.035" | Brass | 1,900 psi @ 72° F | 13/16" | 000000000 | 0000 | 0000 | 0000 |

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 15/16" | 000000000 | 0000 | 0000 | 0000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 1 1/8" | 000000000 | 0000 | 0000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1 5/16" | 000000000 | 0000 | 0000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 5/8" | 000000000 | 0000 | 0000 | 0000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 7/8" | 000000000 | 00000 | 00000 | 00000 |

| A | 3/4" | 0.109" | Brass | 550 psi @ 72° F | 2 3/16" | 000000000 | 00000 | 00000 | 00000 |