Filter by

Maximum Pressure @ Temperature

Fitting Connection

Maximum Temperature

Valve Type

Valve Function

DFARS Specialty Metals

High-Pressure Threaded Precision Flow-Adjustment Valves

316 Stainless Steel Body—Metal-to-Metal Seat

Style | Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Temp. Range, ° F | Packing Material | Port-to-Port Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

BSPP Female × BSPP Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/8 | 0.4 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 1 9/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K68 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/4 | 0.4 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K43 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/4 | 0.4 | 10,000 psi @ 100° F | -100 to 500 | PTFE | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K59 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 3/8 | 0.4 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 1 7/8" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K69 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/2 | 0.46 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K45 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/2 | 0.46 | 10,000 psi @ 100° F | -100 to 500 | PTFE | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K62 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 3/4 | 0.75 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K71 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Male × BSPP Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P | 1/4 | 0.28 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 1 15/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K72 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPT Female × BSPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/8 | 0.4 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 1 9/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | 1/2 | 0.46 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPT Male × BSPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P | 1/2 | 0.46 | 6,000 psi @ 100° F | -100 to 500 | PTFE | 2 11/16" | Oil, Acetone, Air, Ammonia, Diesel Fuel | Needle | 4999K67 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Set Threaded Precision Flow-Adjustment Valves

Brass Body—Straight

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Female × BSPP Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.51 | 2,000 psi @ 400° F | 2 3/16" | 1 3/4" | -15 to 400 | Fluoroelastomer | Brass | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N18 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.53 | 2,000 psi @ 190° F | 2 3/16" | 2 1/2" | -15 to 200 | Fluoroelastomer | Brass | 2 1/2" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.92 | 2,000 psi @ 400° F | 2 5/8" | 2 1/16" | -15 to 400 | Fluoroelastomer | Brass | 2 1/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.93 | 2,000 psi @ 190° F | 3 1/8" | 3 7/16" | -15 to 200 | Fluoroelastomer | Brass | 3 7/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N23 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPT Female × BSPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.25 | 2,000 psi @ 400° F | 1 15/16" | 1 7/16" | -15 to 400 | Fluoroelastomer | Brass | 1 7/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.51 | 2,000 psi @ 400° F | 2 3/16" | 1 3/4" | -15 to 400 | Fluoroelastomer | Brass | 1 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.92 | 2,000 psi @ 400° F | 2 5/8" | 2 1/16" | -15 to 400 | Fluoroelastomer | Brass | 2 1/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5513N13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Body

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Ht. | Lg. | Temp. Range, ° F | Seal Material | Needle Material | End-to-End Lg. | For Use With | Valve Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPT Female × BSPT Female | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.92 | 5,000 psi @ 400° F | 2 5/8" | 2 1/16" | -15 to 400 | Fluoroelastomer | 416 Stainless Steel | 2 1/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5514N12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0.93 | 5,000 psi @ 190° F | 3 1/8" | 3 7/16" | -15 to 200 | Fluoroelastomer | 416 Stainless Steel | 3 7/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5514N15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1.43 | 5,000 psi @ 190° F | 3 9/16" | 3 3/4" | -15 to 200 | Fluoroelastomer | 416 Stainless Steel | 3 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Needle | 5514N16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

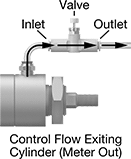

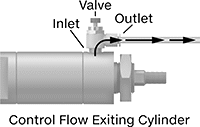

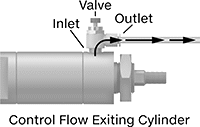

Elbow Air Flow Control Valves

BSPT Male Inlet × Push-to-Connect Female Outlet

|  |  |

Polybutylene Body | Polybutylene Body with Pressure-Release Button | Meter Out |

Flow Rate @ 73 psi, scfm | Flow Rate @ 100 psi, scfm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 4 | 0.15 | — | — | 0 | 4.8 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K521 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 6 | 0.19 | — | — | 0 | 6.1 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K522 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 8 | 0.19 | — | — | 0 | 6.1 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K523 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 4 | 0.22 | — | — | 0 | 7 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K531 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 6 | 0.33 | — | — | 0 | 10.5 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K532 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 8 | 0.39 | — | — | 0 | 12.5 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K533 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 6 | 0.56 | — | — | 0 | 17.9 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K551 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 8 | 0.67 | — | — | 0 | 21.4 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K552 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 10 | 1.33 | — | — | 0 | 42.5 | 150 | 0 to 175 | Dial | Exiting Cylinder (Meter Out) | 62005K56 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body with Pressure-Release Button | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 6 | 0.2 | 0 | 9.28 | — | — | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 62005K171 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 8 | 0.2 | 0 | 9.28 | — | — | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 62005K172 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 6 | 0.2 | 0 | 9.28 | — | — | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 62005K173 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 8 | 0.2 | 0 | 9.28 | — | — | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 62005K174 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Male Inlet × BSPP Female Outlet

|  |

Meter Out |

Flow Rate @ 100 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max., scfm | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc Alloy Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/8 | 0.34 | Not Rated | 12.6 | 145 | 15 to 140 | Dial | Exiting Cylinder (Meter Out) | 6857K25 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4 | 0.61 | Not Rated | 22.6 | 145 | 15 to 140 | Dial | Exiting Cylinder (Meter Out) | 6857K26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

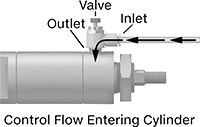

Push-to-Connect Female Inlet × BSPT Male Outlet

|  |

Meter In |

Flow Rate @ 100 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Inlet Tube OD, mm | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/8 | 0.15 | 0 | 4.8 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K421 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/4 | 0.22 | 0 | 7 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K431 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1/8 | 0.19 | 0 | 6.1 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K422 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1/4 | 0.33 | 0 | 10.5 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K432 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3/8 | 0.56 | 0 | 17.9 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K451 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/8 | 0.19 | 0 | 6.1 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K423 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/4 | 0.39 | 0 | 12.5 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K433 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3/8 | 0.67 | 0 | 21.4 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K452 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/2 | 1.33 | 0 | 42.5 | 150 | 0 to 175 | Dial | Entering Cylinder (Meter In) | 62005K46 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Exhaust Flow Control Valves

Overall, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Flow Ports | Inlet Size | Max. Flow Rate @ Pressure | Flow Coefficient (Cv) | Max. Pressure, psi | Body Material | Hex Size, mm | Dia | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Adjustment Dial | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/8 BSPP | 35 scfm @ 100 psi | 1.016 | 145 | Aluminum | — | 16 | 46 | 9164K15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/4 BSPP | 52.5 scfm @ 100 psi | 1.524 | 145 | Aluminum | — | 19.5 | 63.3 | 9164K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/8 BSPP | 59.5 scfm @ 100 psi | 1.728 | 145 | Aluminum | — | 25 | 95.3 | 9164K17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2 BSPP | 141.26 scfm @ 100 psi | 2.982 | 145 | Aluminum | — | 28 | 130 | 9164K109 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/4 BSPP | 268.39 scfm @ 100 psi | 5.965 | 145 | Aluminum | — | 38 | 157 | 9164K111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Adjustment Slotted Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/8 BSPP | 19.21 scfm @ 100 psi | 0.52 | 145 | Aluminum | 14 | 15 | 27 | 9164K101 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/4 BSPP | 37 scfm @ 100 psi | 1 | 145 | Aluminum | 17 | 18.2 | 32.1 | 9164K102 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/8 BSPP | 74 scfm @ 100 psi | 2 | 145 | Aluminum | 22 | 25 | 41.1 | 9164K103 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2 BSPP | 133.2 scfm @ 100 psi | 3.6 | 145 | Aluminum | 24 | 27 | 44.6 | 9164K104 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Adjustment Thumb Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/8 BSPT | 10.59 scfm @ 100 psi | 0.201 | 145 | Brass | 10 | 14 | 35.8 | 9164K107 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/4 BSPT | 17.66 scfm @ 100 psi | 0.313 | 145 | Brass | 14 | 18 | 37 | 9164K108 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dual-Control Two-Direction Air Flow Control Valves

BSPP Female Inlet × BSPP Female Outlet

|  |  |

Meter Out | Meter In |

Flow Rate @ 100 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max., scfm | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/8 | 0.18 | Not Rated | 6.8 | 145 | 0 to 140 | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 8897K12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Air Flow Control Valves

BSPP, BSPT, NPT, NPTF Male Inlet × Push-to-Connect Female Outlet

Flow Rate @ 100 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | For Outlet Tube OD | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/8" | 0.09 | 0 | 5 | 265 | -20 to 175 | Dial | Exiting Cylinder (Meter Out) | 2273K31 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 5/32" | 0.14 | 0 | 7.8 | 265 | -20 to 175 | Slotted Screw | Exiting Cylinder (Meter Out) | 1045K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/4" | 0.22 | 0 | 12.3 | 265 | -20 to 175 | Dial | Exiting Cylinder (Meter Out) | 2273K33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/4" | 0.22 | 0 | 12.3 | 265 | -20 to 175 | Slotted Screw | Exiting Cylinder (Meter Out) | 1045K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4" | 0.27 | 0 | 15.1 | 265 | -20 to 175 | Dial | Exiting Cylinder (Meter Out) | 2273K34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4" | 0.27 | 0 | 15.1 | 265 | -20 to 175 | Slotted Screw | Exiting Cylinder (Meter Out) | 1045K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 3/8" | 0.41 | 0 | 23 | 265 | -20 to 175 | Dial | Exiting Cylinder (Meter Out) | 2273K37 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 3/8" | 0.41 | 0 | 23 | 265 | -20 to 175 | Slotted Screw | Exiting Cylinder (Meter Out) | 1045K17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 3/8" | 0.42 | 0 | 23.5 | 265 | -20 to 175 | Dial | Exiting Cylinder (Meter Out) | 2273K38 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 3/8" | 0.42 | 0 | 23.5 | 265 | -20 to 175 | Slotted Screw | Exiting Cylinder (Meter Out) | 1045K18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Precision Flow-Adjustment Valves

BSPT Female × BSPT Female

Pipe Size | Flow Coefficient (Cv) | Max. Pressure @ Temp. | Temp. Range, ° F | End-to-End Lg. | Valve Type | For Use With | Seal Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass Body with Locking Knob Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 0.2 | 2,000 psi @ 400° F | -15 to 400 | 1 1/2" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Fluoroelastomer/PTFE Plastic | 7822K13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.43 | 2,000 psi @ 400° F | -15 to 400 | 2" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Fluoroelastomer/PTFE Plastic | 7822K11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.78 | 2,000 psi @ 400° F | -15 to 400 | 2 1/4" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Fluoroelastomer/PTFE Plastic | 7822K12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Body with Locking Knob Handle and Internal Check Valve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 0.54 | 2,000 psi @ 400° F | -15 to 400 | 2 3/8" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Fluoroelastomer/PTFE Plastic | 7822K21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 0.83 | 2,000 psi @ 400° F | -15 to 400 | 2 3/4" | Needle | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon | Fluoroelastomer/PTFE Plastic | 7822K22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

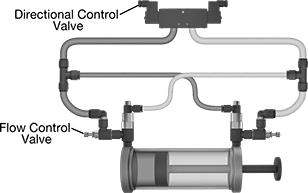

Single-Control Two-Direction Air Flow Control Valves

BSPP Female Inlet × BSPP Female Outlet

|  |  |

Meter Out | Meter In |

Flow Rate @ 100 psi | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max., scfm | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1/8 | 0.19 | Not Rated | 7.17 | 145 | -4 to 140 | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 8642K12 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4 | 0.35 | Not Rated | 12.95 | 145 | -4 to 140 | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 8642K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

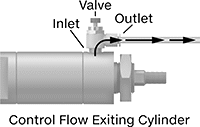

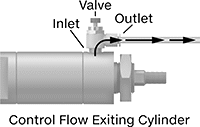

Precision-Adjust Air Flow Control Valves

BSPT Male Inlet × Push-to-Connect Female Outlet

|  |

Meter Out |

Flow Rate @ 73 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 4 | 0.15 | 0 | 7.2 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T11 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 6 | 0.19 | 0 | 9.2 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 8 | 0.19 | 0 | 9.2 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 4 | 0.22 | 0 | 11.2 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 6 | 0.33 | 0 | 15.6 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 8 | 0.39 | 0 | 18.4 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 10 | 0.39 | 0 | 18.4 | 145 | 32 to 140 | Dial | Exiting Cylinder (Meter Out) | 4057T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

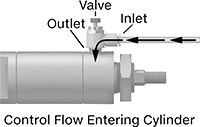

Push-to-Connect Female Inlet × BSPT Male Outlet

|  |

Meter In |

Flow Rate @ 73 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Inlet Tube OD, mm | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/8 | 0.15 | 0 | 7.2 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T18 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1/4 | 0.22 | 0 | 11.2 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T22 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1/8 | 0.19 | 0 | 9.2 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1/4 | 0.33 | 0 | 15.6 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T23 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/8 | 0.19 | 0 | 9.2 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T21 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/4 | 0.39 | 0 | 18.4 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T24 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/4 | 0.39 | 0 | 18.4 | 145 | 32 to 140 | Dial | Entering Cylinder (Meter In) | 4057T25 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Elbow Air Flow Control Valves with Flow Indicator

BSPT Male Inlet × Push-to-Connect Female Outlet

Flow Rate @ 73 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body with Flow Indicator | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 6 | 0.17 | 0 | 5.2 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 2768N25 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 8 | 0.17 | 0 | 5.2 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 2768N26 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Elbow Corrosion-Resistant Air Flow Control Valves

BSPT Male Inlet × Push-to-Connect Female Outlet

|  |

Meter Out |

Flow Rate @ 73 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | For Outlet Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polybutylene Body with Pressure-Release Button | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 6 | 0.07 | 0 | 2.6 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 9066K52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 8 | 0.07 | 0 | 2.6 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 9066K53 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 8 | 0.07 | 0 | 2.6 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | 9066K54 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

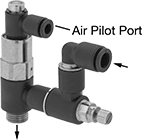

Air-Operated Air Flow Control Valves with Safety Shut-Off

Push-to-Connect Female Inlet × BSPP Male Outlet × Push-to-Connect Female Air Pilot

Flow Rate @ 87 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Inlet Tube OD, mm | Outlet Pipe Size | For Air Pilot Tube OD, mm | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Body—One Direction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 1/4 | 4 | Not Rated | 0 | 16.77 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 2747N114 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 1/8 | 4 | Not Rated | 0 | 8.48 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 2747N115 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3/8 | 4 | Not Rated | 0 | 30.9 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 2747N116 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 3/8 | 4 | Not Rated | 0 | 33.2 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out) | Pressure-Release Button | 2747N117 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inline Air Flow Control Valves with Flow Indicator

BSPP Female Inlet × BSPP Female Outlet

|  |  |

Meter Out | Meter In |

Flow Rate @ 73 psi, scfm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inlet Pipe Size | Outlet Pipe Size | Flow Coefficient (Cv) | Min. | Max. | Max. Pressure, psi | Temp. Range, ° F | Flow Adjustment Mechanism | Flow Control Location (ISO Designation) | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body with Flow Indicator | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1/4 | 0.82 | 0 | 32.4 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 3019N121 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 3/8 | 0.82 | 0 | 32.4 | 145 | 25 to 140 | Dial | Exiting Cylinder (Meter Out), Entering Cylinder (Meter In) | 3019N122 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||