Round Plastic Batch Cans

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 14 3/4" | 20 1/2" | 13" | 3/16" | 1 gal. | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Round Plastic Batch Cans

For technical drawings and 3-D models, click on a part number.

| Capacity, gal. | Dia. | Ht. | Bottom ID | Thick. | Graduation Marks | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 14 3/4" | 20 1/2" | 13" | 3/16" | 1 gal. | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

Food Industry Round Metal Batch Cans

These metal batch cans meet NSF/ANSI 2 standards for food-processing equipment.

For technical drawings and 3-D models, click on a part number.

Narrow-Mouth Round Stainless Steel Batch Cans

Also known as milk cans, these have a narrow mouth for controlled pouring. They have a reinforced bottom to minimize wear and tear when sliding cans along the floor. The lid has two 7/16" dia. holes for attaching a tag.

| Capacity, gal. | Dia. | Ht. | Mouth OD | Gauge | Appearance | Lid Type | Each | |

304 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 10 | 13 1/4" | 23 3/4" | 7 1/2" | 18 | Dull | Tight Fitting | 000000 | 0000000 |

Round Stainless Steel Batch Cans with Faucet

A built-in faucet allows easy dispensing.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Appearance | Faucet Material | Seal Material | Each | |

304 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 13 1/4" | 19" | 13 1/4" | 18 | Dull | 316 Stainless Steel | PTFE Plastic | 0000000 | 0000000 |

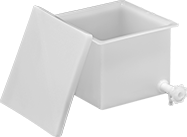

Rectangular Plastic Batch Cans with Faucet

A built-in faucet allows easy dispensing.

For technical drawings and 3-D models, click on a part number.

Bottom Inside | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Faucet Material | Seal Material | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||||

| 10 | 19 3/4" | 15" | 10" | 18" | 13" | 1/4" | White | Semi-Clear | Loose Fitting | Polyethylene Plastic | PTFE Plastic | 175° | Stackable | Seamless | 0000000 | 0000000 |

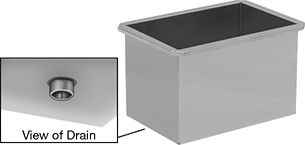

Rectangular Stainless Steel Batch Cans

316 stainless steel is more corrosion resistant than 304 stainless steel.

Batch cans with drain have a drain centered on the bottom of the can.

For technical drawings and 3-D models, click on a part number.

Steel Drums

All drums are UN-compliant for shipping.

Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 | 0000000 |

Each | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 0000000 | 0000000 | 0000000 |

Openings | Each | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Pipe Size | Gender | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | |||||||||||||||

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A2/X120/S | 00000000 | 0000000 | 0000000 |

Openings | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Color | Pipe Size | Gender | Space Saving Features | Shipping Standard | 1-3 | 4-Up | |

Painted Steel | ||||||||||||

| 10 | 15" | 19 1/4" | 20 | Not Rated | Black | 2 NPSM, 3/4 NPSM | Female | Stackable | UN1A1/X1.4/250 | 0000000 | 0000000 | 000000 |

Each | |||

|---|---|---|---|

| For Drum Capacity, gal. | 1-3 | 4-Up | |

| 16, 10 | 00000000 | 00000 | 00000 |

Corrosion-Resistant Steel Drums

The inside of these drums is epoxy coated to resist rust. Drums are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 00000000 | 0000000 |

Leverlock Closing Ring

and Lid with No Openings

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

Painted Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | Black | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 00000000 | 0000000 |

| For Drum Capacity, gal. | Gauge | Each | |

Lid with No Openings | |||

|---|---|---|---|

| 16, 10 | 20 | 00000000 | 000000 |

Stainless Steel Drums

These drums are corrosion resistant and are UN-compliant for shipping.

| Cap., gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Cap., lbs. | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15" | 19" | 14" | 20 | 250 | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 |

Openings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Gauge | Weight Cap. | Pipe Size | Gender | Space Saving Features | Shipping Standard | Each | |

304 Stainless Steel | ||||||||||

| 10 | 15" | 19" | 20 | Not Rated | 2 BSPP, 3/4 BSPP | Female | Stackable | UN1A1/X1.4/250 | 0000000 | 0000000 |

304 Stainless Steel | ||||

|---|---|---|---|---|

| For Drum Capacity, gal. | Gauge | Seal Material | Each | |

Lid with No Openings | ||||

| 16, 10, 8 | 20 | EPDM Rubber | 0000000 | 0000000 |

| For Drum Capacity, gal. | Each | |

| 16, 10 | 00000000 | 00000 |

| For Drum Capacity, gal. | Each | |

Nut-and-Bolt Closing Ring | ||

|---|---|---|

| 16, 10 | 00000000 | 000000 |

Food Industry Stainless Steel Drums

In addition to being corrosion resistant, these drums have smooth, welded seams to prevent food and chemicals from collecting in crevices.

Closed-head drums have a lid that’s permanently sealed, so the only way to access the contents inside is through the two lid openings. They’re often used to hold wine and other liquids because they’re less likely to leak or spill than open-head drums. All are UN compliant for shipping.

Drums | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Connection | Replacement Drum Plugs for Pipe Size 3/4 | Replacement Drum Plugs for Pipe Size 2 | ||||||||||||||

| Capacity, gal. | Dia. | Ht. | Bottom ID | Gauge | Weight Capacity | Seal Material | Gender | Thread Type | Pipe Size | Shipping Standard | Each | Each | Each | |||

304 Stainless Steel | ||||||||||||||||

| 10 | 14 1/2" | 19 1/2" | 14" | 18 | Not Rated | PTFE Plastic | Female | NPSM | 3/4, 2 | UN1A1/X1.8/550 | 00000000 | 0000000 | 00000000 | 000000 | 00000000 | 000000 |

Salvage/Overpack Drums

Use these drums for secondary containment or for temporarily storing and transporting leaking containers. All drums are UN-compliant for shipping.

| For Drum Cap., gal. | Cap., gal. | Weight Cap., lbs. | Dia. | Ht. | Bottom ID | Inside Ht. | Gauge | Color | Lid Color | Seal Material | Closing Ring Material | Space Saving Features | Shipping Standard | Each | |

With Nut-and-Bolt Closing Ring | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 250 | 14 1/4" | 19 1/4" | 14" | 17" | 20 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X120/S, UN1A2/Y1.8/150 | 0000000 | 0000000 |

With Leverlock Closing Ring | |||||||||||||||

| 5 | 10 | 250 | 14 1/4" | 19" | 14" | 17" | 20 | Yellow | Red | EPDM Rubber | Steel | Stackable | UN1A2/X120/S | 0000000 | 000000 |

Rubber and Plastic Tubs

These tubs are crack and dent resistant.

For technical drawings and 3-D models, click on a part number.

Easy-Grip Plastic Waste Containers, Lids, Dollies, and Caddies

These containers have two molded-in side handles and a durable bottom that stands up to dragging across the floor. They meet NSF/ANSI standards for food equipment.

Metal Waste Containers with Lift-Off Lid

A galvanized finish protects these waste containers from rust.

| Capacity, gal. | Dia. | Ht. | Circumference | For Use Outdoors | Material | Each | ||

| A | 10 | 15 1/2" | 15 1/2" | 49" | Yes | Galvanized Steel | 000000 | 000000 |

Plastic Step-Open Waste Containers

Open these plastic waste containers with your foot to discard trash without touching the lid. They help you comply with OSHA sanitation standards, which require storing waste that does not leak and keeps out rodents.

FM-approved waste containers prevent internal fires by restricting oxygen flow.

Style D waste containers are designed to temporarily store potential biohazards. They’re red in color, have a biohazard label, and won’t leak, so they’re consistent with OSHA 29 CFR 1910.1030 requirements for exposure to blood-borne pathogens.

| Style | Capacity, gal. | Dia. | Ht. | Circumference | Mobility | Message | Specifications Met | Color | Each | |

| D | 10 | 18" | 18" | 57" | Stationary | Biohazard | FM Approved, OSHA Compliant 29 CFR 1910.1030 | Red | 0000000 | 0000000 |

Wall-Mount Waste Containers

Safety Containers for Oily Waste

For temporary storage of oil- and solvent-soaked towels and brushes, these containers protect flammable contents from potential fire sources and spontaneous combustion.

Styles C and D have a raised ventilated bottom to promote air circulation and heat dispersion.

| Style | Capacity, gal. | Dia. | Ht. | Lid Type | Message | Specifications Met | Features | Choose a Color | Each | |

Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | 10 | 18" | 18" | Step Open | Empty Every Night | FM Approved | __ | 00000000 | 0000000 | |

Steel | ||||||||||

| C | 10 | 14" | 18 1/2" | Flip Up | Empty Every Night | FM Approved, UL Listed | Raised Bottom | 0000000 | 00000 | |

| D | 10 | 14" | 18 1/2" | Step Open | Empty Every Night | FM Approved, UL Listed | Raised Bottom | 0000000 | 000000 | |