Filter by

ID

Mount Type

Bottom Plate Material

Number of Lines

Base Material

Number of Mounting Points

Top Plate Material

Clamping Fastener Material

Performance

Minimum Temperature

Maximum Temperature

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Clamp Type

About Leveling Mounts

Choose the right leveling mounts for your floor conditions, equipment weight, and vibration-control needs.

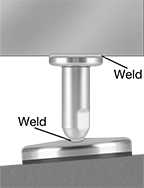

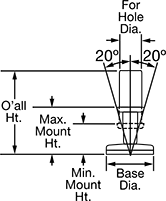

Sanitary Weld-On Swivel Leveling Mounts

With Rubber Cushion | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Hole Dia., mm | Mounting Ht., mm | Swivel Range of Motion | Base Dia., mm | Food Industry Std. | Cap. per Mount, lb. | Overall Ht., mm | Cushion Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Base and Stud | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 52 | 56 to 85 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62 | 63 to 92 | 20° | 109 | FDA Compliant 21 CFR 177.2600 | 6,000 | 151 | Buna-N | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Weld Wear Plates

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Overall Thk. | Thick. | Material | Score Interval | Hardness Rating | Hardness | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cast Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 9 1/2" | 1" | 5/16" | Low-Carbon Steel | 1 1/2" | Extra Hard | Rockwell C64 | Yes | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

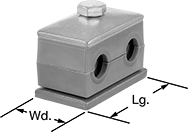

Multiline Weld-On Vibration-Damping Block Routing Clamps

|

Routing Clamps | Stacking Clamps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inch | Metric, mm | For Pipe Size | Lg. | Wd. | Ht. | Max. Pressure, psi | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Top Plate and Zinc-Phosphate-Coated Steel Bottom Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 8 | — | 1 7/16" | 1 3/16" | 1 3/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 12 | 1/8 | 1 7/16" | 1 3/16" | 1 3/16" | 2,000 | 00000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 14 | 1/8 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 14 | 1/4 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 15 | 1/4 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/16" | 18 | 3/8 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 20 | 1/2 | 2 3/4" | 1 3/16" | 1 11/16" | 2,000 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 25 | 1/2 | 2 3/4" | 1 3/16" | 1 11/16" | 2,000 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 28 | 3/4 | 3 3/8" | 1 3/16" | 1 13/16" | 2,000 | 00000000 | 00000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 30 | — | 3 3/8" | 1 3/16" | 1 13/16" | 2,000 | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 35 | 1 | 4 5/16" | 1 3/16" | 2 5/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 11/16" | 42 | 1 1/4 | 4 5/16" | 1 3/16" | 2 5/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Top and Bottom Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 8 | — | 1 7/16" | 1 3/16" | 1 3/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 12 | 1/8 | 1 7/16" | 1 3/16" | 1 3/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 14 | 1/8 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 14 | 1/4 | 2 3/16" | 1 3/16" | 1 1/4" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 20 | 1/2 | 2 3/4" | 1 3/16" | 1 11/16" | 2,000 | 0000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 22 | 1/2 | 2 3/4" | 1 3/16" | 1 11/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 28 | 3/4 | 3 3/8" | 1 3/16" | 1 13/16" | 2,000 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/16" | 30 | — | 3 3/8" | 1 3/16" | 1 13/16" | 2,000 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 35 | 1 | 4 5/16" | 1 3/16" | 2 5/16" | 2,000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||