Valve Handle Lockouts

Stop gas and fluid valve handles from opening and closing during maintenance. Valve lockouts like these help you comply with OSHA 29 CFR 1910.147, which requires handles on pneumatic and hydraulic systems to be locked out during maintenance to prevent injuries.

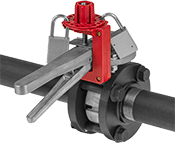

Slide-on lockouts fit onto the valve handle; the valve body prevents the handle from turning. All of these lockouts work on closed handles, but some also work on open ones. Style C lockouts have a cylinder and end cap that you place over your valve.

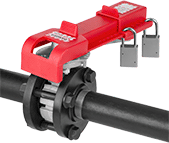

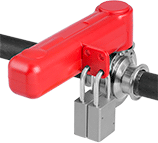

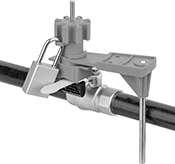

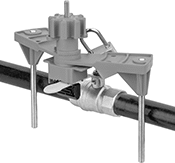

Clamp-on lockouts adjust to fit a range of handle sizes. Style F lockouts wedge compression handles, preventing them from being squeezed to stop your valve from operating.

Hinged lockouts secure the valve handle in any position. They have a one-piece design that stays together for easy storage.

For Handle | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Slide On—Locks in Closed and Open Position | ||||||||||

Plastic | ||||||||||

| 1"-6" | 1/8"-1 5/8" | 1" | 1 | 9/32" | -20° to 200° | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

| For Handle Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Clamp On—Locks in Closed and Open Position | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Plastic | ||||||||||

| 1/8"-1/2" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0° to 245° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 |

| 1/4"-1" | 3/4" | 2 | 3/8" | 304 Stainless Steel | 0° to 245° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

Clamp On—Locks in Closed Position | ||||||||||

Plastic | ||||||||||

| 1/8"-2 1/4" | __ | 4 | 1/4" | 304 Stainless Steel | -20° to 140° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

| 2"-4" | __ | 4 | 1/4" | 304 Stainless Steel | -20° to 140° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

For Handle | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Clamp On—Locks in Closed Position | ||||||||||

Plastic | ||||||||||

| __ | 3/4"-1 1/2" | 1" | 6 | 9/32" | -20° to 200° | Red | Yes | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

Clamp On | ||||||||||

Plastic | ||||||||||

| 3/4"-2" | __ | 3/4" | 2 | 9/32" | 0° to 175° | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 |

For Handle | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Temp. Range, °F | Color | Label Included | Specifications Met | Each | |

Hinged—Locks in Closed and Open Position | ||||||||||

Plastic | ||||||||||

| 1/2"-8" | 3/4"-2" | 3/4" | 4 | 5/16" | -40° to 210° | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 |

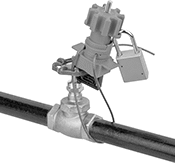

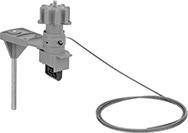

Universal Valve Lockouts

Lock out most valves in your facility with just one device. These lockouts clamp onto a variety of valve handwheels and handles. They’re great for large levers, T-handles, wheels with odd shapes and sizes, and other handles that are hard to secure with specialized lockouts. However, they’re slower to install than specialized lockouts—you’ll have to configure different attachments depending on your handle type. These lockouts help you comply with OSHA 29 CFR 1910.147 requirements for the control of hazardous energy.

To install, first turn your handle to the off position. After assembling your lockout with all necessary attachments, clamp the body to your handle and turn the lockout wheel to tighten. Add a padlock to prevent removal of the lockout.

Each lockout comes with a blocking arm. Wedge the arm against a pipe or other surface in the direction the handle turns in—this will block its movement. If your handle turns in either direction, attach an additional blocking arm (sold separately).

For valve handles that turn with a squeeze trigger, clamp the lockout body to the handle so it wedges between the handle and the trigger.

For handwheels, clamp the lockout body to the edge of the wheel and run the included cable through the spokes and around a nearby pipe or surface. Then pull the cable through the lockout body for a tight hold.

Nylon cable resists corrosion, so it’s good for use in damp areas or on wet or greasy pipes. It also resists many common chemicals. Even as it wears, it won’t scuff surfaces and stays nonconductive.

Metal cable lasts longer than nylon cable. A vinyl coating protects it from rust and prevents it from scuffing surfaces.

Lockouts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cable | Additional Blocking Arms | ||||||||||||

| For Handle Thick. | Min. Padlock Vertical Shackle Clearance | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Clamp Material | Dia. | Lg., ft. | Temperature Range, °F | Color | Features | Each | Each | ||

Nylon Cable | |||||||||||||

Clamp On—Locks in Closed Position | |||||||||||||

Plastic | |||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 000000 |

| 1/4" to 1" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 00000 |

Vinyl-Coated Metal Cable | |||||||||||||

Clamp On—Locks in Closed Position | |||||||||||||

Plastic | |||||||||||||

| 1/8" to 1/2" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 00000 | 0000000 | 00000 |

| 1/4" to 1" | 3/4" | 2 | 3/8" | Stainless Steel | 1/8" | 8 | 0° to 245° | Red | Blocking Arm | 0000000 | 000000 | 0000000 | 00000 |