Economy Carbide Inserts

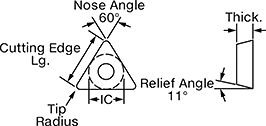

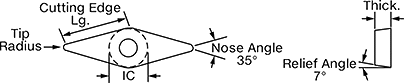

Install these carbide inserts into a matching holder. When a cutting edge becomes dull, rotate the insert in the holder to use a sharp edge. Larger nose angles and larger tip radii provide a stronger cutting edge but result in increased vibration and a rougher finish.

Positive-rake inserts have an edge that is less than 90° to sit flat in the holder for improved cutting clearance and a better finish than negative-rake inserts. They have cutting edges on one side.

Coated inserts last longer and can be run at faster speeds than uncoated inserts.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

| Insert Code | For Tool Bit Code | Finish | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | Rake Type | For Cutting Operation | Each | |

For Use On Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| TPMT-221 | AR-6, AL-6, BR-6, BL-6, E-6 | Uncoated | 1/4" | 1/8" | 0.38" | 1/64" | Positive | Medium | 00000000 | 000000 |

| TPMT-221 | AR-6, AL-6, BR-6, BL-6, E-6 | Titanium Nitride (TiN) Coated | 1/4" | 1/8" | 0.38" | 1/64" | Positive | Medium | 00000000 | 00000 |

| TPMT-222 | AR-6, AL-6, BR-6, BL-6, E-6 | Uncoated | 1/4" | 1/8" | 0.38" | 1/32" | Positive | Medium | 00000000 | 00000 |

| TPMT-222 | AR-6, AL-6, BR-6, BL-6, E-6 | Titanium Nitride (TiN) Coated | 1/4" | 1/8" | 0.38" | 1/32" | Positive | Medium | 00000000 | 00000 |

| TPMT-321 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Uncoated | 3/8" | 1/8" | 0.56" | 1/64" | Positive | Medium | 00000000 | 00000 |

| TPMT-321 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Titanium Nitride (TiN) Coated | 3/8" | 1/8" | 0.56" | 1/64" | Positive | Medium | 00000000 | 00000 |

| TPMT-322 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Uncoated | 3/8" | 1/8" | 0.56" | 1/32" | Positive | Medium | 00000000 | 00000 |

| TPMT-322 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Titanium Nitride (TiN) Coated | 3/8" | 1/8" | 0.56" | 1/32" | Positive | Medium | 00000000 | 00000 |

| TPMT-431 | AR-16, AL-16, BR-16, BL-16, E-16 | Uncoated | 1/2" | 3/16" | 0.8" | 1/64" | Positive | Medium | 00000000 | 00000 |

| TPMT-431 | AR-16, AL-16, BR-16, BL-16, E-16 | Titanium Nitride (TiN) Coated | 1/2" | 3/16" | 0.8" | 1/64" | Positive | Medium | 00000000 | 00000 |

| TPMT-432 | AR-16, AL-16, BR-16, BL-16, E-16 | Uncoated | 1/2" | 3/16" | 0.75" | 1/32" | Positive | Medium | 00000000 | 00000 |

| TPMT-432 | AR-16, AL-16, BR-16, BL-16, E-16 | Titanium Nitride (TiN) Coated | 1/2" | 3/16" | 0.75" | 1/32" | Positive | Medium | 00000000 | 00000 |

| Insert Code | For Tool Bit Code | Finish | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | Rake Type | For Cutting Operation | Pkg. Qty. | Pkg. | |

For Use On Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TPMT-221 | AR-6, AL-6, BR-6, BL-6, E-6 | Uncoated | 1/4" | 1/8" | 0.38" | 1/64" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-221 | AR-6, AL-6, BR-6, BL-6, E-6 | Titanium Nitride (TiN) Coated | 1/4" | 1/8" | 0.38" | 1/64" | Positive | Medium | 10 | 0000000 | 000000 |

| TPMT-222 | AR-6, AL-6, BR-6, BL-6, E-6 | Uncoated | 1/4" | 1/8" | 0.38" | 1/32" | Positive | Medium | 10 | 0000000 | 00000 |

| TPMT-222 | AR-6, AL-6, BR-6, BL-6, E-6 | Titanium Nitride (TiN) Coated | 1/4" | 1/8" | 0.38" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-321 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Uncoated | 3/8" | 1/8" | 0.56" | 1/64" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-321 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Titanium Nitride (TiN) Coated | 3/8" | 1/8" | 0.56" | 1/64" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-322 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Uncoated | 3/8" | 1/8" | 0.56" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-322 | AR-8, AR-10, AR-12, AL-8, AL-10, AL-12, BR-8, BR-10, BR-12, BL-8, BL-10, BL-12, E-8, E-10, E-12 | Titanium Nitride (TiN) Coated | 3/8" | 1/8" | 0.56" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-431 | AR-16, AL-16, BR-16, BL-16, E-16 | Uncoated | 1/2" | 3/16" | 0.8" | 1/64" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-431 | AR-16, AL-16, BR-16, BL-16, E-16 | Titanium Nitride (TiN) Coated | 1/2" | 3/16" | 0.8" | 1/64" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-432 | AR-16, AL-16, BR-16, BL-16, E-16 | Uncoated | 1/2" | 3/16" | 0.75" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

| TPMT-432 | AR-16, AL-16, BR-16, BL-16, E-16 | Titanium Nitride (TiN) Coated | 1/2" | 3/16" | 0.75" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

| Insert Code | For Tool Bit Code | Finish | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | Rake Type | For Cutting Operation | Each | |

For Use On Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VCMT-32.52 | VR-8, VR-10, VR-12, VR-16, VL-8, VL-10, VL-12, VL-16, VE-8, VE-10, VE-12, VE-16 | Uncoated | 3/8" | 5/32" | 0.65" | 1/32" | Positive | Medium | 00000000 | 000000 |

| VCMT-32.52 | VR-8, VR-10, VR-12, VR-16, VL-8, VL-10, VL-12, VL-16, VE-8, VE-10, VE-12, VE-16 | Titanium Nitride (TiN) Coated | 3/8" | 5/32" | 0.65" | 1/32" | Positive | Medium | 00000000 | 00000 |

| Insert Code | For Tool Bit Code | Finish | Inscribed Circle Dia. (IC) | Thick. | Cutting Edge Lg. | Tip Radius | Rake Type | For Cutting Operation | Pkg. Qty. | Pkg. | |

For Use On Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| VCMT-32.52 | VR-8, VR-10, VR-12, VR-16, VL-8, VL-10, VL-12, VL-16, VE-8, VE-10, VE-12, VE-16 | Uncoated | 3/8" | 5/32" | 0.65" | 1/32" | Positive | Medium | 10 | 00000000 | 0000000 |

| VCMT-32.52 | VR-8, VR-10, VR-12, VR-16, VL-8, VL-10, VL-12, VL-16, VE-8, VE-10, VE-12, VE-16 | Titanium Nitride (TiN) Coated | 3/8" | 5/32" | 0.65" | 1/32" | Positive | Medium | 10 | 00000000 | 000000 |

Cutoff and Grooving Carbide Inserts

Attach these carbide inserts to a holder to perform cutoff and grooving tasks on a lathe.

C5 carbide inserts hold up better than C2 carbide inserts when making cuts in steel, stainless steel, and cast iron. Titanium nitride (TiN) coated inserts last longer than uncoated inserts, and you can run them at faster speeds.

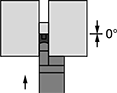

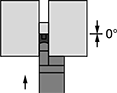

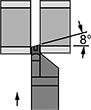

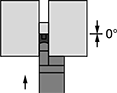

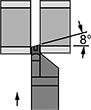

Neutral inserts have a 0° lead angle for cutting solid workpieces. Both right- and left-hand inserts have an 8° lead angle for cutting hollow workpieces, such as pipe and tubing. Use right-hand inserts when the workpiece is rotating counterclockwise, or toward you. Use left-hand inserts when the workpiece rotates clockwise, or away from you.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Blade-style holders (sold separately) require a tool block for mounting.

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Left Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 00000000 | 0000 | 10 | 00000000 | 00000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 0000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.315" | 0.315" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.354" | 0.378" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.354" | 0.378" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Left Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Insert Thick. | Max. Dp. of Cut | Lg. | Wd. | Ht. | Material | Insert Extractor Included | Each | |

| 0.087", 0.094" | 1.5" | 3 3/8" | 0.063" | 3/4" | Steel | Yes | 00000000 | 000000 |

| 0.087", 0.094" | 2" | 4 5/16" | 0.063" | 1 1/32" | Steel | Yes | 00000000 | 00000 |

| 0.122" | 3" | 4 5/16" | 0.094" | 1 1/32" | Steel | Yes | 00000000 | 00000 |

| 0.122" | 4" | 5 7/8" | 0.094" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

| 0.161" | 3" | 4 5/16" | 1/8" | 1 1/32" | Steel | Yes | 00000000 | 00000 |

| 0.161", 0.187" | 4" | 5 7/8" | 1/8" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

| 0.201" | 5" | 5 7/8" | 0.156" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

| 0.252" | 5" | 5 7/8" | 0.203" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

| 0.315" | 5.5" | 5 7/8" | 0.268" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

| 0.354" | 5.5" | 5 7/8" | 0.312" | 1 1/4" | Steel | Yes | 00000000 | 000000 |

Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Insert Thick. | Max. Dp. of Cut | Wd. | Ht. | Overall Lg. | Material | Insert Extractor Included | Each | |

| 0.087", 0.094" | 0.55" | 3/8" | 3/8" | 3 3/8" | Steel | Yes | 0000000 | 000000 |

| 0.087", 0.094" | 0.58" | 3/8" | 1/2" | 4 5/16" | Steel | Yes | 0000000 | 00000 |

| 0.087", 0.094" | 0.63" | 1/2" | 3/4" | 4 5/16" | Steel | Yes | 0000000 | 000000 |

| 0.122" | 0.63" | 3/8" | 1/2" | 4 5/16" | Steel | Yes | 0000000 | 00000 |

| 0.122" | 0.63" | 1/2" | 5/8" | 4 5/16" | Steel | Yes | 0000000 | 00000 |

| 0.122" | 0.7" | 1/2" | 3/4" | 4 5/16" | Steel | Yes | 0000000 | 000000 |

| 0.122" | 1.03" | 1" | 1" | 5 7/8" | Steel | Yes | 0000000 | 000000 |

| 0.161" | 0.66" | 5/8" | 1/2" | 4 5/16" | Steel | Yes | 00000000 | 00000 |

| 0.161" | 0.76" | 3/4" | 1/2" | 4 5/16" | Steel | Yes | 00000000 | 00000 |

| 0.161" | 1.25" | 1" | 1" | 5 7/8" | Steel | Yes | 0000000 | 000000 |

| 0.187", 0.201" | 0.76" | 3/4" | 1/2" | 4 5/16" | Steel | Yes | 00000000 | 00000 |

| 0.187", 0.201" | 1.5" | 1" | 1" | 5 7/8" | Steel | Yes | 0000000 | 000000 |

Indexable Cutoff and Grooving Carbide Inserts

Cut square corner grooves in a workpiece or cut completely through a part. Pair an insert with a compatible holder. When the first cutting edge dulls, flip the insert to use the other edge, giving it twice the life of a standard cutoff and grooving insert.

| Thick. | Max. Dp. of Cut | Lg. | Lead Angle | Radius | Material | Material Grade | Finish | For Use On | Each | |

Neutral | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.079" | 0.04" | 0.866" | 0° | 0.079" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 000000 |

| 0.118" | 0.06" | 0.866" | 0° | 0.118" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.157" | 0.08" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.197" | 0.1" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.236" | 0.12" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| Thick. | Max. Dp. of Cut | Lg. | Lead Angle | Radius | Material | Material Grade | Finish | For Use On | Pkg. Qty. | Pkg. | |

Neutral | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.079" | 0.04" | 0.866" | 0° | 0.079" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 0000000 |

| 0.118" | 0.06" | 0.866" | 0° | 0.118" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

| 0.157" | 0.08" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

| 0.197" | 0.1" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

| 0.236" | 0.12" | 0.984" | 0° | 0.157" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

Indexable Grooving and Profiling Carbide Inserts

The rounded nose on these inserts contours the outside of the workpiece and cuts grooves with rounded edges. Pair an insert with a compatible shank-style holder. When the first cutting edge dulls, flip the insert to use the other edge, giving it twice the life of a standard grooving insert.

| Thick. | Max. Dp. of Cut | Lg. | Lead Angle | Radius | Material | Material Grade | Finish | For Use On | Each | |

Neutral | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.118" | 0.06" | 0.866" | 0° | 0.059" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 000000 |

| 0.157" | 0.08" | 0.984" | 0° | 0.079" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| 0.197" | 0.1" | 0.984" | 0° | 0.118" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 0000000 | 00000 |

| Thick. | Max. Dp. of Cut | Lg. | Lead Angle | Radius | Material | Material Grade | Finish | For Use On | Pkg. Qty. | Pkg. | |

Neutral | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.118" | 0.06" | 0.866" | 0° | 0.059" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 0000000 |

| 0.157" | 0.08" | 0.984" | 0° | 0.079" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

| 0.197" | 0.1" | 0.984" | 0° | 0.118" | Carbide | C5 | Titanium Aluminum Nitride (TiAlN) Coated | Aluminum, Cast Iron, Stainless Steel, Steel | 10 | 00000000 | 000000 |

Carbide-Tipped External Threading Lathe Tools

The carbide tip brazed onto the ground steel shank of these tools is more wear resistant than high-speed steel tips. Right-handed tools cut from right to left, left-handed tools cut from left to right, and neutral tools can cut in either direction.

C5 carbide tips perform better than C2 carbide tips when making cuts in steel, stainless steel, and cast iron. Harder than C6 carbide tips, they also handle higher speeds when cutting steel.

Tool Bit | Shank | Tip | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Code | Wd. | Ht. | Thread Type | Thread Shape | Overall Lg. | Nose Angle | Lg. | Thick. | For Use On | Each | |

Neutral | ||||||||||||

C5 Carbide | ||||||||||||

| E | E-4 | 1/4" | 1/4" | UNC, UNS, UNF | V | 2" | 60° | 5/16" | 1/16" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel, Titanium | 00000000 | 00000 |

| E | E-5 | 5/16" | 5/16" | UNC, UNS, UNF | V | 2 1/4" | 60° | 3/8" | 3/32" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel, Titanium | 00000000 | 00000 |

| E | E-6 | 3/8" | 3/8" | UNC, UNS, UNF | V | 2 1/2" | 60° | 1/2" | 3/32" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel, Titanium | 00000000 | 0000 |

| E | E-8 | 1/2" | 1/2" | UNC, UNS, UNF | V | 3 1/2" | 60° | 1/2" | 1/8" | Aluminum, Brass, Bronze, Cast Iron, Nickel, Stainless Steel, Steel, Titanium | 00000000 | 0000 |

Blade-Style Holders for Cutoff and Grooving Carbide Inserts

Install one of these holders into a tool block for right- and left-hand mounting in a lathe. Pair with a carbide insert (sold separately) to make the exact cutoff and grooving tool you need. These holders have a tapered opening at each end.

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Dp. of Cut | Lg. | Wd. | Ht. | For Insert Thick. | Material | Insert Extractor Included | Each | |

| 1.5" | 3 3/8" | 0.063" | 3/4" | 0.087", 0.094" | Steel | Yes | 00000000 | 000000 |

| 2" | 4 5/16" | 0.063" | 1 1/32" | 0.087", 0.094" | Steel | Yes | 00000000 | 00000 |

| 3" | 4 5/16" | 0.094" | 1 1/32" | 0.122" | Steel | Yes | 00000000 | 00000 |

| 3" | 4 5/16" | 1/8" | 1 1/32" | 0.161" | Steel | Yes | 00000000 | 00000 |

| 4" | 5 7/8" | 0.094" | 1 1/4" | 0.122" | Steel | Yes | 00000000 | 000000 |

| 4" | 5 7/8" | 1/8" | 1 1/4" | 0.161", 0.187" | Steel | Yes | 00000000 | 000000 |

| 5" | 5 7/8" | 0.156" | 1 1/4" | 0.201" | Steel | Yes | 00000000 | 000000 |

| 5" | 5 7/8" | 0.203" | 1 1/4" | 0.252" | Steel | Yes | 00000000 | 000000 |

| 5.5" | 5 7/8" | 0.268" | 1 1/4" | 0.315" | Steel | Yes | 00000000 | 000000 |

| 5.5" | 5 7/8" | 0.312" | 1 1/4" | 0.354" | Steel | Yes | 00000000 | 000000 |

Combine a holder and carbide insert to perform cutoff and grooving tasks on a lathe.

Right-hand inserts have an 8° lead angle for cutting hollow workpieces such as pipe and tubing.

C2 carbide is abrasion resistant and less likely to chip or crack than C5 carbide when cutting aluminum, brass, and bronze.

C5 carbide holds up better than C2 carbide when making cuts in steel, stainless steel, and cast iron.

Coated inserts last longer and can be run at faster speeds than uncoated inserts.

Inserts sold individually come packed in a clear plastic case to protect cutting edges during shipment. Inserts sold in packs come factory sealed from the manufacturer for maximum traceability.

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.354" | 0.378" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

Left Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 00000000 | 0000 | 10 | 00000000 | 00000 |

| 0.161" | 0.161" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Left Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 00000000 | 0000 | 10 | 00000000 | 00000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 0000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.315" | 0.315" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.354" | 0.378" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.252" | 0.252" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

| 0.354" | 0.378" | 0.595" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Left Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |

Mount blade-style holders to a lathe tool post or turret.

Shank | Overall | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| (Web) Table Pivot | For Holder Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Material | Each | |

| 1 | 3 3/8" | 5/8" | 1/2" | 3" | 1" | 1 3/8" | Steel | 00000000 | 0000000 |

| 2 | 4 5/16" | 5/8" | 5/8" | 3 1/2" | 1 1/4" | 1 3/4" | Steel | 00000000 | 000000 |

| 3 | 4 5/16", 4 7/16" | 3/4" | 3/4" | 3 1/2" | 1 1/2" | 2" | Steel | 00000000 | 000000 |

| 4 | 5 7/8" | 3/4" | 3/4" | 4 1/2" | 1 3/4" | 2" | Steel | 00000000 | 000000 |

| 4 | 5 7/8" | 7/8" | 1" | 4 1/2" | 2" | 2 1/8" | Steel | 00000000 | 000000 |

| 4 | 5 7/8" | 1 1/8" | 1 1/4" | 4 1/2" | 2 1/4" | 2 3/8" | Steel | 00000000 | 000000 |

| 4 | 5 7/8" | 1 5/8" | 1 1/2" | 4 1/2" | 2 1/4" | 2 7/8" | Steel | 00000000 | 000000 |

Shank-Style Holders for Cutoff and Grooving Carbide Inserts

Fit these holders directly into a lathe tool post or appropriately sized holder without the need for a tool block. Pair with a carbide insert (sold separately) to make the exact cutoff and grooving tool you need. These holders have a tapered opening at one end.

Shank | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Dp. of Cut | Wd. | Ht. | O'all Lg. | For Insert Thick. | Material | Insert Extractor Included | Each | |

| 0.55" | 3/8" | 3/8" | 3 3/8" | 0.087", 0.094" | Steel | Yes | 0000000 | 000000 |

| 0.58" | 3/8" | 1/2" | 4 5/16" | 0.087", 0.094" | Steel | Yes | 0000000 | 00000 |

| 0.63" | 3/8" | 1/2" | 4 5/16" | 0.122" | Steel | Yes | 0000000 | 00000 |

| 0.63" | 1/2" | 5/8" | 4 5/16" | 0.122" | Steel | Yes | 0000000 | 00000 |

| 0.63" | 1/2" | 3/4" | 4 5/16" | 0.087", 0.094" | Steel | Yes | 0000000 | 000000 |

| 0.66" | 5/8" | 1/2" | 4 5/16" | 0.161" | Steel | Yes | 00000000 | 00000 |

| 0.7" | 1/2" | 3/4" | 4 5/16" | 0.122" | Steel | Yes | 0000000 | 000000 |

| 0.76" | 3/4" | 1/2" | 4 5/16" | 0.161" | Steel | Yes | 00000000 | 00000 |

| 0.76" | 3/4" | 1/2" | 4 5/16" | 0.187", 0.201" | Steel | Yes | 00000000 | 00000 |

| 1.03" | 1" | 1" | 5 7/8" | 0.122" | Steel | Yes | 0000000 | 000000 |

| 1.25" | 1" | 1" | 5 7/8" | 0.161" | Steel | Yes | 0000000 | 000000 |

| 1.5" | 1" | 1" | 5 7/8" | 0.187", 0.201" | Steel | Yes | 0000000 | 000000 |

Combine a holder and carbide insert to perform cutoff and grooving tasks on a lathe.

Neutral inserts have a 0° lead angle for cutting solid workpieces.

Right-hand inserts have an 8° lead angle for cutting hollow workpieces such as pipe and tubing.

C5 carbide holds up better than C2 carbide when making cuts in steel, stainless steel, and cast iron.

Coated inserts last longer and can be run at faster speeds than uncoated inserts.

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 00000 |

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Each | Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Thick. | Groove Wd. | Lg. | Radius | Each | Pkg. Qty. | Pkg. | ||

Neutral | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 000000 | 10 | 00000000 | 0000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

Right Hand | ||||||||

| 0.087" | 0.087" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.094" | 0.094" | 0.385" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.122" | 0.122" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.161" | 0.161" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.187" | 0.187" | 0.525" | 0.008" | 0000000 | 00000 | 10 | 00000000 | 000000 |

| 0.201" | 0.201" | 0.515" | 0.008" | 00000000 | 00000 | 10 | 00000000 | 000000 |