Speed-Monitoring Switches

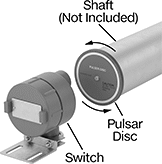

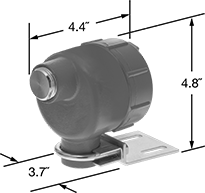

Detect unwanted slowdowns in a rotary shaft that could cause machine damage and downtime. These switches are often used on drivetrains, conveyors, and other power-driven components. They come with a pulser disc, which you’ll need to attach to the shaft by drilling and tapping a hole. Once mounted, the disc rotates with the shaft and creates magnetic signals that the switch senses. When the speed falls below a set point, the switch will trigger an alarm or turn off the system.

Switches are UL listed and rated NEC Class I, Divisions 1 and 2, Groups C and D; and Class II, Divisions 1 and 2, Groups E, F, and G. They have an explosion-proof housing and are also rated NEMA 4X for washdown and corrosion protection.

Switching | Input | Conduit | Mounting Slot | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activation Point Range, rpm | Current, A | Voltage | Voltage | Frequency, Hz | No. of Terminals | Trade Size | Thread Type | Gender | Lg. | Wd. | No. of | Mounting Fasteners Included | Environmental Rating | Each | |

1 Off (Normally Open), 1 On (Normally Closed) Starting Switch Position | |||||||||||||||

SPDT | |||||||||||||||

| 5-100 | 5 | 120V AC | 120V AC | 60 | 5 | 1 | NPT | Female | 1 1/4" | 0.32" | 2 | Yes | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups E, F, G NEMA 4X | 0000000 | 0000000 |

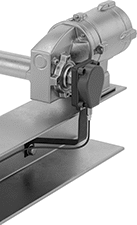

Roller-Conveyor-Mount Speed-Monitoring Transmitters

Keep your conveyor’s rollers turning at the right speed to reduce downtime caused by jams. These transmitters send signals to your programmable logic controller (PLC), so it can switch circuits on or off when a roller reaches a set speed. No need to drill a mounting hole—they attach by magnet.

Transmitters with 2 wire leads can track if rollers are moving either too slow or too fast, but not both at once. Transmitters with 3 wire leads can simultaneously monitor whether rollers are moving too slow or too fast.

| Speed Range, rpm | Signal Output Type | Input Voltage | Current Output | No. of Wire Leads | Lg. | Wd. | Ht. | Housing Material | Cable Lead Lg., ft. | Temp. Range, °F | Environmental Rating | Each | |

| 1-2,000 | NPN | 10V DC-30V DC | 200mA | 3 | 2.9" | 2.7" | 4" | Polypropylene Plastic | 20 | -10° to 155° | IP67 | 00000000 | 0000000 |

| 1-2,000 | NPN, PNP | 10V DC-55V DC | 400mA | 2 | 2.9" | 2.7" | 4" | Polypropylene Plastic | 20 | -10° to 155° | IP67 | 00000000 | 000000 |