Filter by

Material

System of Measurement

Maximum Temperature

For Use With

Edge Seal Style

Minimum Temperature

Backing Type

Color

For Use Outdoors

RoHS

Certification

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Military Specification

Core Material

Flange Thickness

Profile Shape

Ultra-High- and Low-Temperature Rope Seals

Wd. | Temp. Range, ° F | For Use Outdoors | Mil. Spec. | Color | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ceramic Fiber—Plain-Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -300 to 1,100 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-High- and Low-Temperature Ultra-Conformable Rope Seals

|

Wd. | Temp. Range, ° F | For Use Outdoors | Mil. Spec. | Color | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ceramic Fiber—Plain-Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -300 to 2,300 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -300 to 2,300 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -300 to 2,300 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -300 to 2,300 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -300 to 2,300 | No | MIL-I-24244 | White | 5 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

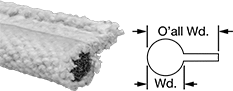

Ultra-High-Temperature Chemical-Resistant Flanged Rope Seals

Overall Wd. | Wd. | Flange Thk. | Core Material | Max. Temp., ° F | For Use Outdoors | Color | Choose a Length, ft. | Per Ft. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ceramic Fabric—Plain-Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3/8" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/2" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 3/4" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/2" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 3/16" | Inconel 625 Nickel | 1,700 | No | White | 1 , 10 , 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||