ER-20 Collets

Install into an ER-20 collet chuck or holder to tightly grip round-shank tool bits in milling machines. To ensure they work with milling machines and tooling made throughout the world, these collets meet both ISO and DIN dimensional standards.

Collets with coolant seals keep tools cool to extend tool life.

| Collet Size | Grip Range | Workpiece Dia. Tolerance | Max. Body Dia. | Approximate Dia. Compression | Overall Lg. | Material | Features | Max. Coolant Pressure, psi | Specifications Met | Each | |

Round | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 0.047"-0.063" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 000000 |

| 3/32" | 0.078"-0.094" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 1/8" | 0.109"-0.125" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 5/32" | 0.125"-0.156" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 3/16" | 0.156"-0.187" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 3/16" | 0.183"-0.187" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | Coolant Seal | 1,000 | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 7/32" | 0.187"-0.219" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 1/4" | 0.219"-0.250" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 1/4" | 0.234"-0.250" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | Coolant Seal | 1,000 | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 9/32" | 0.250"-0.281" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 5/16" | 0.281"-0.312" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 11/32" | 0.312"-0.344" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 3/8" | 0.344"-0.375" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 3/8" | 0.359"-0.375" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | Coolant Seal | 1,000 | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 13/32" | 0.375"-0.406" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 7/16" | 0.406"-0.437" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 15/32" | 0.437"-0.469" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 1/2" | 0.469"-0.500" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 1/2" | 0.484"-0.500" | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | Coolant Seal | 1,000 | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 3mm | 2.5 mm-3 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 4mm | 3.5 mm-4 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 5mm | 4 mm-5 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 6mm | 5 mm-6 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 000000 | 00000 |

| 7mm | 6 mm-7 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 8mm | 7 mm-8 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 10mm | 9 mm-10 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

| 12mm | 11 mm-12 mm | -0.0001" to 0.0001" | 0.83" | 1/32" | 1.22" | Hardened Steel | __ | __ | DIN 6499, ISO 15488B | 0000000 | 00000 |

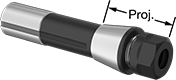

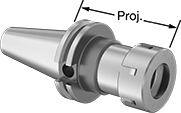

Collet Chucks

Securely hold collets in the spindle of a milling machine.

Use a nut wrench (sold separately) to tighten the chuck nut and secure the tool bit in the collet.

ER-20 Collet Stands

Overall | Mounting Slot | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Number of Collets | Ht. | Wd. | Dp. | No. of | Wd. | Lg. | Material | Each | |

| 36 | 1 3/8" | 9 1/8" | 7 7/32" | 2 | 1/4" | 1 1/16" | Steel | 0000000 | 000000 |

Collet Fixtures

Pair these fixtures with collets to tightly grip workpieces for machining. You can mount them on milling machines, drill presses, and other work surfaces. However, they’re not for use with lathes, grinders, or high-speed rotary tables. All have a through hole to accommodate long workpieces.

Collet nut fixtures convert ER collets—typically used to hold tool bits—into holders for cylindrical workpieces. The tapered, slit design of the collet distributes clamping force evenly around a workpiece. This creates a stable, consistent grip that keeps your workpiece from shifting, even under 5-axis machining forces. These fixtures are made of steel to withstand the high clamping forces and frequent cycles of production environments.

Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Each | |

| ER-20 | 1/2" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 0000000 |