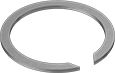

Speared Ends External Retaining Rings

Often used with small engines, heavy equipment, and power transmission, these external retaining rings have speared ends to help you install and remove them. They’re constant-section style, which means the distance between their inside and outside diameter is consistent, so the clearance around their circumference doesn’t change either. All are made of spring steel for good strength and reliability. To resist corrosion in dry environments, they’re oil coated.

For Groove | Ring | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For OD | Diameter | Width | ID | Thickness | Minimum Hardness | Thrust Load Capacity, lbs. | Magnetic Properties | Pkg. Qty. | Pkg. | |

Oil-Coated 1060-1090 Spring Steel | ||||||||||

| 5/16" | 0.29" | 0.028" | 0.281" | 0.025" | Rockwell C42 | 180 | Magnetic | 10 | 000000000 | 00000 |

| 3/8" | 0.351" | 0.028" | 0.341" | 0.025" | Rockwell C42 | 230 | Magnetic | 10 | 000000000 | 0000 |

| 7/16" | 0.412" | 0.028" | 0.402" | 0.025" | Rockwell C42 | 300 | Magnetic | 10 | 000000000 | 0000 |

| 1/2" | 0.474" | 0.039" | 0.464" | 0.035" | Rockwell C42 | 460 | Magnetic | 10 | 000000000 | 0000 |

| 5/8" | 0.597" | 0.039" | 0.586" | 0.035" | Rockwell C42 | 520 | Magnetic | 10 | 000000000 | 0000 |

| 3/4" | 0.716" | 0.046" | 0.703" | 0.042" | Rockwell C42 | 820 | Magnetic | 10 | 000000000 | 0000 |

| 7/8" | 0.835" | 0.046" | 0.82" | 0.042" | Rockwell C42 | 1,110 | Magnetic | 10 | 000000000 | 0000 |

| 1" | 0.956" | 0.046" | 0.941" | 0.042" | Rockwell C42 | 1,200 | Magnetic | 10 | 000000000 | 0000 |

| 1 1/8" | 1.075" | 0.056" | 1.06" | 0.05" | Rockwell C42 | 1,880 | Magnetic | 10 | 000000000 | 0000 |

| 1 1/4" | 1.194" | 0.056" | 1.179" | 0.05" | Rockwell C42 | 2,090 | Magnetic | 10 | 000000000 | 0000 |

| 1 3/8" | 1.309" | 0.056" | 1.291" | 0.05" | Rockwell C42 | 2,300 | Magnetic | 10 | 000000000 | 0000 |

| 1 1/2" | 1.43" | 0.056" | 1.408" | 0.05" | Rockwell C42 | 2,500 | Magnetic | 10 | 000000000 | 0000 |

| 1 5/8" | 1.551" | 0.068" | 1.527" | 0.062" | Rockwell C42 | 3,190 | Magnetic | 10 | 000000000 | 0000 |

| 1 3/4" | 1.67" | 0.068" | 1.64" | 0.062" | Rockwell C42 | 3,510 | Magnetic | 5 | 000000000 | 0000 |

| 1 7/8" | 1.789" | 0.068" | 1.759" | 0.062" | Rockwell C42 | 3,760 | Magnetic | 5 | 000000000 | 0000 |

| 2" | 1.91" | 0.068" | 1.88" | 0.062" | Rockwell C42 | 4,010 | Magnetic | 5 | 000000000 | 0000 |

| 2 1/8" | 2.027" | 0.086" | 1.997" | 0.078" | Rockwell C42 | 5,470 | Magnetic | 5 | 000000000 | 0000 |

| 2 1/4" | 2.146" | 0.086" | 2.116" | 0.078" | Rockwell C42 | 5,790 | Magnetic | 5 | 000000000 | 0000 |

| 2 3/8" | 2.265" | 0.086" | 2.235" | 0.078" | Rockwell C42 | 6,400 | Magnetic | 5 | 000000000 | 00000 |

| 2 1/2" | 2.386" | 0.086" | 2.356" | 0.078" | Rockwell C42 | 6,600 | Magnetic | 5 | 000000000 | 00000 |

| 2 5/8" | 2.505" | 0.086" | 2.475" | 0.078" | Rockwell C42 | 6,800 | Magnetic | 5 | 000000000 | 00000 |

| 2 3/4" | 2.624" | 0.103" | 2.594" | 0.093" | Rockwell C42 | 8,460 | Magnetic | 5 | 000000000 | 00000 |

| 2 7/8" | 2.743" | 0.103" | 2.713" | 0.093" | Rockwell C42 | 8,840 | Magnetic | 5 | 000000000 | 00000 |

| 3" | 2.86" | 0.103" | 2.83" | 0.093" | Rockwell C42 | 9,230 | Magnetic | 5 | 000000000 | 00000 |

For Groove | Ring | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For OD, mm | Diameter, mm | Width, mm | ID, mm | Thickness, mm | Minimum Hardness | Thrust Load Capacity, lbs. | Magnetic Properties | Pkg. Qty. | Pkg. | |

Oil-Coated 1060-1090 Spring Steel | ||||||||||

| 12 | 11.1 | 1.17 | 10.69 | 1.07 | Rockwell C42 | 250 | Magnetic | 10 | 000000000 | 00000 |

| 15 | 14 | 1.35 | 13.67 | 1.19 | Rockwell C42 | 440 | Magnetic | 10 | 000000000 | 0000 |

| 17 | 16 | 1.35 | 15.65 | 1.19 | Rockwell C42 | 520 | Magnetic | 10 | 000000000 | 0000 |

| 20 | 18.6 | 1.73 | 18.03 | 1.57 | Rockwell C42 | 820 | Magnetic | 10 | 000000000 | 0000 |

| 25 | 23.5 | 1.73 | 23.11 | 1.57 | Rockwell C42 | 1,440 | Magnetic | 10 | 000000000 | 0000 |

| 30 | 28.2 | 2.16 | 27.76 | 1.91 | Rockwell C42 | 1,880 | Magnetic | 10 | 000000000 | 0000 |

| 35 | 32.7 | 2.74 | 32.13 | 2.36 | Rockwell C42 | 2,250 | Magnetic | 10 | 000000000 | 00000 |

| 40 | 37.2 | 2.74 | 36.88 | 2.36 | Rockwell C42 | 2,710 | Magnetic | 10 | 000000000 | 00000 |

| 45 | 41.9 | 2.74 | 41.28 | 2.36 | Rockwell C42 | 3,550 | Magnetic | 10 | 000000000 | 00000 |

| 50 | 46.8 | 2.74 | 46.23 | 2.36 | Rockwell C42 | 3,880 | Magnetic | 5 | 000000000 | 00000 |

| 55 | 51.2 | 3.05 | 50.67 | 2.77 | Rockwell C42 | 6,000 | Magnetic | 5 | 000000000 | 00000 |

| 60 | 56.2 | 3.05 | 55.55 | 2.77 | Rockwell C42 | 6,300 | Magnetic | 5 | 000000000 | 00000 |

| 70 | 65.7 | 3.53 | 64.92 | 3.18 | Rockwell C42 | 8,460 | Magnetic | 1 | 000000000 | 0000 |

| 75 | 70.7 | 3.53 | 69.85 | 3.18 | Rockwell C42 | 9,030 | Magnetic | 1 | 000000000 | 0000 |

| 85 | 80.7 | 3.53 | 79.73 | 3.18 | Rockwell C42 | 10,180 | Magnetic | 1 | 000000000 | 0000 |

| 90 | 84.9 | 3.53 | 84.02 | 3.18 | Rockwell C42 | 11,980 | Magnetic | 1 | 000000000 | 00000 |

| 105 | 99.9 | 4.42 | 98.76 | 3.96 | Rockwell C42 | 14,110 | Magnetic | 1 | 000000000 | 00000 |

| 110 | 104.9 | 4.42 | 103.63 | 3.96 | Rockwell C42 | 15,000 | Magnetic | 1 | 000000000 | 00000 |

Low-Clearance External Retaining Rings

Also known as constant-section rings, these rings have open ends and a profile that does not taper like other external retaining rings. Use them with linear bearings on support rail shafts. Open rings with flat-tip retaining ring pliers (sold separately), pass them over the end of a shaft, and release to spring into the groove. The black-phosphate finish is mildly corrosion resistant in dry environments.

For Groove | Ring | ||||||

|---|---|---|---|---|---|---|---|

| For OD | Dia. | Wd. | OD | Thick. | Magnetic Properties | Each | |

Black-Phosphate Steel | |||||||

| 1/2" | 0.474" | 0.039" | 0.55" | 0.035" | Magnetic | 0000000 | 00000 |

| 5/8" | 0.596" | 0.039" | 0.673" | 0.035" | Magnetic | 0000000 | 0000 |

| 7/8" | 0.82" | 0.046" | 0.923" | 0.042" | Magnetic | 0000000 | 0000 |

| 1 1/8" | 1.07" | 0.056" | 1.18" | 0.05" | Magnetic | 0000000 | 0000 |

| 1 1/4" | 1.178" | 0.056" | 1.301" | 0.05" | Magnetic | 0000000 | 0000 |

| 1 9/16" | 1.47" | 0.068" | 1.62" | 0.062" | Magnetic | 0000000 | 0000 |

| 2" | 1.89" | 0.068" | 2.04" | 0.062" | Magnetic | 0000000 | 0000 |

| 2 3/8" | 2.245" | 0.086" | 2.448" | 0.078" | Magnetic | 0000000 | 0000 |

| 8 1/2" Lg. Steel Flat-Tip Retaining Ring Pliers | 0000000 | Each | 000000 |