Filter by

Length

Width

Component

Number of Holes

Finish

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Clamp Type

Reach Length

Adjustment Mechanism

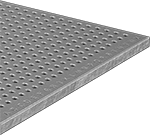

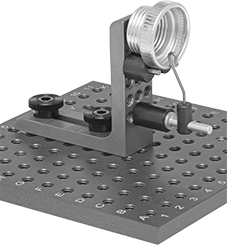

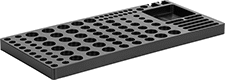

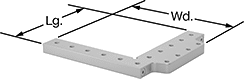

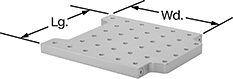

Fixture Plates

Fixture Plates

Holes | Bolt-On Mount | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Parallel Tolerance | No. of | Ctr.-to-Ctr. | Mounting Fasteners Included | No. of Mounting Holes | Mounting Hole Style | For Mounting Fastener Thread Size | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3" | 1/2" | 0.025" | 21 | 1/2" | Yes | 4 | Counterbored | 1/4"-20 | Anodized Aluminum | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 6" | 1/2" | 0.025" | 51 | 1/2" | Yes | 4 | Counterbored | 1/4"-20 | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 3/8" | 0.025" | 121 | 1/2" | — | — | — | — | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 3/8" | Not Rated | 121 | 1/2" | — | — | — | — | Acrylic Plastic | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/2" | 0.005" | 484 | 1/2" | — | — | — | — | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 18" | 1/2" | 0.01" | 1,156 | 1/2" | — | — | — | — | Anodized Aluminum | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 3/4" | 0.01" | 2,116 | 1/2" | — | — | — | — | Anodized Aluminum | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 300 mm | 19 mm | Not Rated | 324 | 15 mm | — | — | — | — | Acrylic Plastic | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 150 mm | 150 mm | 10 mm | 0.635 mm | 81 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 300 mm | 13 mm | 0.635 mm | 324 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 450 mm | 450 mm | 13 mm | 0.635 mm | 729 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 600 mm | 600 mm | 19 mm | 0.635 mm | 1,369 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 300 mm | 13 mm | 0.635 mm | 289 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 450 mm | 450 mm | 13 mm | 0.635 mm | 729 | 15 mm | — | — | — | — | Anodized Aluminum | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

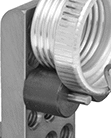

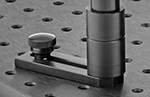

Quick-Change Adapters

Magnetic Mount | Bolt-On Mount | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Max. Magnetic Pull, lbf | No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Holes | For Mounting Fastener Thread Size | Mounting Hole Ctr.-to-Ctr. | Material | Each | |||

| 6" | 1" | 1/2" | 3.5 | 1 | Yes | 2 | 10-32 | 5 1/2" | Anodized Aluminum | 0000000 | 0000000 | ||

| 180 mm | 30 mm | 13 mm | 3.5 | 1 | Yes | 2 | M6 | 147 mm | Anodized Aluminum | 0000000 | 000000 | ||

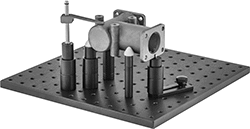

Fixturing for Parts Inspection

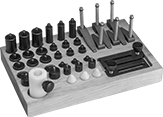

Kits

|

No. of Pieces | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

M6 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 42 | 2 Hold-Down Clamps—38 mm Reach × 38 mm O'all Ht. 4 Hold-Down Clamps—58 mm Reach × 75 mm O'all Ht. 3 Standoffs—13 mm Dia. × 20 mm Ht. 3 Standoffs—13 mm Dia. × 25 mm Ht. 3 Standoffs—13 mm Dia. × 50 mm Ht. 3 Standoffs—19 mm Dia. × 20 mm Ht. 3 Standoffs—19 mm Dia. × 25 mm Ht. 3 Standoffs—19 mm Dia. × 50 mm Ht. 3 Standoffs—25 mm Dia. × 20 mm Ht. 3 Standoffs—25 mm Dia. × 25 mm Ht. 3 Standoffs—25 mm Dia. × 50 mm Ht. 1 Adjustable-Height Standoff—13 mm Dia. 2 Pin Supports—13 mm Dia. × 25 mm Ht. 3 Cone Supports 1 Positioning Plate—35 mm Lg. 1 Positioning Plate—76 mm Lg. 1 Acetal Plastic Tray | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixture Towers

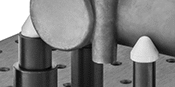

Standoffs

|

Adjustable Standoff Height |

Dia. | Ht. | Thread Lg. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Standoff Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/2" | 1/4" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1/2" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 2" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/2" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/4" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3" | 1/4" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable Standoff Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 7/16" to 1 3/4" | 1/4" | Aluminum | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Standoff Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 25 mm | 3.8 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Standoff Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 10 mm | 6.2 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 25 mm | 6.2 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 50 mm | 6.2 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 75 mm | 6.2 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Standoff Height | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 15 mm | 7.7 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 mm | 25 mm | 7.5 mm | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

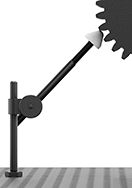

Any-Angle Cone Supports

|  |

Arm Lg. | Body Lg. | Arm Rotation | Thread Lg. | Body Material | Cone Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 4" | 360° | 1 1/8" | Steel | Acetal | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Height Sleeves

|  |

For Standoff Dia. | Dia. | Ht. | Material | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1 1/8" | 2" | Acetal | 1/4"-20 Knurled Knob | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Positioners

Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Lg. | Wd. | Number of Holes | Material | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8-32, 10-32 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 1 1/2" | 1/4" | 1" | 9/32" | 6, 4 | Steel | 1/4"-20 Knurled Knob | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 5/8" | 1/4" | 7/8" | 9/32" | 1 | Steel | 1/4"-20 Knurled Knob | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 1 3/4" | 9/32" | 1 | Steel | 1/4"-20 Knurled Knob | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 mm | 25 mm | 10 mm | 30 mm | 6.5 mm | 1 | Steel | Two M6 Knurled Knobs | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 mm | 20 mm | 10 mm | 30 mm | 8.5 mm | 1 | Steel | Two M8 Knurled Knobs | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corner Plates

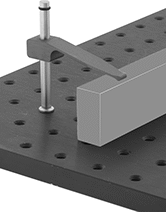

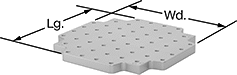

Quick-Change Fixture Plates

Fixture Plates

|  |

1 Mounting Edge | 4 Mounting Edges |

Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Parallel Tolerance | No. of | Ctr.-to-Ctr. | Max. Magnetic Pull, lbf | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 1/2" | 0.005" | 36 | 1" | 3.5 | Anodized Aluminum | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 12" | 1/2" | 0.005" | 72 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 12" | 1/2" | 0.005" | 237 | 1/2" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 18" | 1/2" | 0.005" | 108 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 6" | 1/2" | 0.005" | 72 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/2" | 0.005" | 144 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 18" | 1/2" | 0.005" | 216 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 18" | 1/2" | 0.005" | 324 | 1" | 3.5 | Anodized Aluminum | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 24" | 1/2" | 0.005" | 432 | 1" | 3.5 | Anodized Aluminum | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Mounting Edge—M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 mm | 180 mm | 13 mm | 0.127 mm | 81 | 20 mm | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 180 mm | 360 mm | 13 mm | 0.127 mm | 162 | 20 mm | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 360 mm | 360 mm | 13 mm | 0.127 mm | 324 | 20 mm | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 360 mm | 540 mm | 13 mm | 0.127 mm | 486 | 20 mm | 3.5 | Anodized Aluminum | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4 Mounting Edges—1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 6" | 1/2" | 0.005" | 52 | 1" | 3.5 | Anodized Aluminum | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

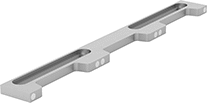

Mounting Rails

Magnetic Mount | Bolt-On Mount | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Thk. | Max. Magnetic Pull, lbf | No. of Mounting Edges | Mounting Fasteners Included | No. of Mounting Slots | Mounting Slot Lg. | Mounting Slot Wd. | Material | Each | |||

| 18" | 2" | 1/2" | 3.5 | 3 | No | 2 | 5 7/16" | 1/2" | Anodized Aluminum | 0000000 | 0000000 | ||

| 30" | 2" | 1/2" | 3.5 | 5 | No | 6 | 3 1/8" | 1/2" | Anodized Aluminum | 0000000 | 000000 | ||

| 540 mm | 50 mm | 13 mm | 3.5 | 3 | No | 3 | 120 mm | 13 mm | Anodized Aluminum | 0000000 | 000000 | ||

| 720 mm | 50 mm | 13 mm | 3.5 | 4 | No | 6 | 68 mm | 13 mm | Anodized Aluminum | 0000000 | 000000 | ||

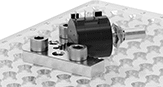

Clamps for Parts Inspection

Hold-Down Clamps

Clamps | Replacement Mounting Shafts | Replacement Clamp Arms | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Reach Lg. | Ht. | Thread Lg. | Material | Tip Finish | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tension Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 1" | 1/4" | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/16" | 2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 2 3/4" | 1/4" | Aluminum | Rubber Coated | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 7/16" | 3" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 50 mm | 4.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 mm | 50 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 mm | 75 mm | 6.2 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wire Tension Spring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thumb Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1 1/2" | 3/8" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 2 1/2" | 1/4" | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/8" | 3 1/2" | 3/8" | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 mm | 38 mm | 9.5 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 76 mm | 63 mm | 6.4 mm | Aluminum | — | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 112 mm | 89 mm | 9.5 mm | Aluminum | — | 0000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Squeeze Tabs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3" | 3/8" | Plastic | — | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm Threads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 83 mm | 76 mm | 9.5 mm | Plastic | — | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

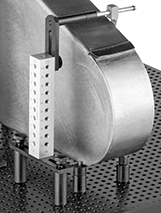

Fixture Tables for Parts Inspection

Tables

Overall | Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Wt. Cap., lb. | Plate Thk. | No. of | Ctr.-to-Ctr. | Flatness Tolerance | Frame Material | Plate Material | Wheel Configuration | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4"-20 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47 1/4" | 35 3/8" | 35 3/8" | 880 | 3/4" | 1,564 | 1" | 0.005" | Aluminum | Aluminum | Four Swivel Casters | Leveling Casters, Numbered and Lettered Holes | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 Hole Thread Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,200 mm | 900 mm | 900 mm | 880 | 19 mm | 1,645 | 25 mm | 0.127 mm | Aluminum | Aluminum | Four Swivel Casters | Leveling Casters, Numbered and Lettered Holes | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Calibration Squares

Tolerance per 6" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Finished Edges | No. of Finished Faces | Lg. | Wd. | Ht. | Flatness | Squareness | Parallel | Color | Material | Surface Plate Grade | Certificate Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tri-Squares | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1 | 12" | 9" | 3" | 0.00005" | 0.00005" | — | Black | Granite | Laboratory Grade AA | Calibration Certificate Traceable to NIST | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Squares | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1 | 12" | 12" | 3" | 0.00005" | 0.00005" | 0.00005" | Black | Granite | Laboratory Grade AA | Calibration Certificate Traceable to NIST | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||