Filter by

For Joining

Container Type

For Use On

Consistency

Reaches Full Strength

Adhesive Type

Container Size

Begins to Harden

Maximum Temperature

Shear Strength

Clarity

Viscosity

Peel Strength

Minimum Temperature

Export Control Classification Number (ECCN)

DFARS Specialty Metals

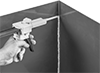

About Structural Adhesives

More