Filter by

Base Length

Base Width

Mounting Position

Height

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Length

Center Through-Hole Diameter

Sold As

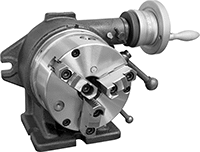

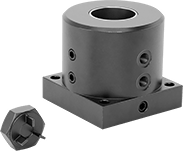

Indexing Collet Fixtures

Air-Operated Collet Fixtures

Mounting Holes | Air Inlet | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sold As | For Collet Type | For Max. Workpiece Dia. | Dia. | Ht. | Max. Clamping Pressure, psi | Max. Air Pressure, psi | Material | No. of | Dia. | Mounting Position | No. of Air Ports | Connection Port | Pipe Size | Thread Type | Gender | Power Source | Includes | Each | ||

| Individual | 5C | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | Air | — | 0000000 | 0000000 | |

| Kit | 5C | 1 1/16" | 5 1/2" | 3 1/4" | 1,125 | 150 | Aluminum | 4 | 3/8" | Vertical | 2 | Hose | 1/4 | NPS | Male | Air | Air-Operated Fixture, Four-Way Foot-Operated Air Valve, Three 6-ft. Long Air Hoses | 0000000 | 000000 | |

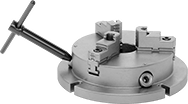

Stationary Clamping Jaw Fixtures

3 Reversible Jaws

For Workpiece | Base | Mounting Slots | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | ID | Ctr. Through-Hole Dia. | Dia. | Ht. | Dia. | Ht. | Material | No. of | Wd. | Includes | Each | ||

| 5/16" to 6 5/16" (8 to 160 mm) | 1 7/8" to 5 29/32" (48 to 150 mm) | 1 25/32" (45 mm) | 6 11/16" (170 mm) | 1 9/16" (40 mm) | 8 21/32" (220 mm) | 11/16" (18 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 | |

| 7/16" to 7 7/8" (11 to 200 mm) | 2 7/16" to 7 1/2" (62 to 190 mm) | 2 3/8" (60 mm) | 8 1/4" (210 mm) | 1 25/32" (45 mm) | 10 5/8" (270 mm) | 25/32" (20 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

| 15/32" to 9 27/32" (12 to 250 mm) | 2 27/32" to 9 7/16" (72 to 240 mm) | 3 5/32" (80 mm) | 10 1/32" (255 mm) | 2 3/32" (53 mm) | 12 13/32" (315 mm) | 25/32" (20 mm) | Steel | 4 | 5/8" (16 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

| 19/32" to 11 13/16" (15 to 300 mm) | 3 3/8" to 11 13/32" (86 to 290 mm) | 4 1/8" (105 mm) | 12" (305 mm) | 2 9/32" (58 mm) | 14 9/16" (370 mm) | 7/8" (22 mm) | Steel | 4 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

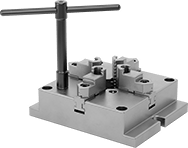

4 Reversible Jaws

For Workpiece | Base | Mounting Slots | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | ID | Ctr. Through-Hole Dia. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Material | No. of | Wd. | Includes | Each | ||

| 5/32" to 5 1/32" (4 to 128 mm) | 2 5/32" to 5 1/32" (55 to 128 mm) | 1 19/32" (40 mm) | 6 1/2" (165 mm) | 6 1/2" (165 mm) | 1 17/32" (39 mm) | 8 15/32" (215 mm) | 6 1/2" (165 mm) | 11/16" (18 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 | |

| 3/16" to 6 3/8" (5 to 162 mm) | 2 7/16" to 6 3/8" (62 to 162 mm) | 2 5/32" (55 mm) | 7 7/8" (200 mm) | 7 7/8" (200 mm) | 1 25/32" (45 mm) | 9 27/32" (250 mm) | 7 7/8" (200 mm) | 25/32" (20 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

| 1/4" to 7 7/8" (6 to 200 mm) | 2 27/32" to 7 7/8" (72 to 200 mm) | 2 3/4" (70 mm) | 9 27/32" (250 mm) | 9 27/32" (250 mm) | 1 31/32" (50 mm) | 12 7/32" (310 mm) | 9 27/32" (250 mm) | 7/8" (22 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

| 13/32" to 10 7/16" (10 to 265 mm) | 3 9/16" to 10 7/16" (90 to 265 mm) | 3 15/16" (100 mm) | 12 7/32" (310 mm) | 12 7/32" (310 mm) | 2 3/8" (60 mm) | 14 31/32" (380 mm) | 12 7/32" (310 mm) | 1" (25 mm) | Steel | 2 | 7/8" (22 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 | |

Indexing Jaw-Chuck Fixtures

3 Reversible Jaws

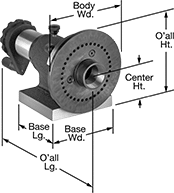

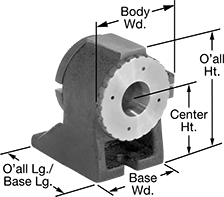

Jaw Fixtures | Tailstocks | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece | Overall | Base | Tolerance | Mounting Slots | ||||||||||||||||||

OD | ID | Index Increments | Lathe Chuck Dia. | Ctr. Through-Hole Dia. | Ctr. Ht. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Parallel | Squareness | Material | No. of | Wd. | Includes | Each | Each | |||

| 13/32" to 6 5/32" (10 to 155 mm) | 5/32" to 1 21/32" (4 to 42 mm) | 15°, 30°, 45°, 60°, 90°, 120°, 180° | 6" | 1 3/4" | 5" | 9 7/8" | 8 3/4" | 10 7/16" | 8 5/8" | 5 7/8" | 9 1/4" | 0.0002" | 0.0002" | Steel | 5 | 5/8" | One Chuck Wrench | 0000000 | 000000000 | 0000000 | 0000000 | |

| 13/32" to 7 3/32" (10 to 180 mm) | 5/32" to 2 7/16" (4 to 62 mm) | 15°, 30°, 45°, 60°, 90°, 120°, 180° | 8" | 2 1/2" | 6 1/4" | 12 1/4" | 9 9/16" | 11 5/8" | 8 7/8" | 6 1/4" | 11 1/4" | 0.0002" | 0.0002" | Steel | 5 | 5/8" | One Chuck Wrench | 0000000 | 00000000 | 0000000 | 000000 | |

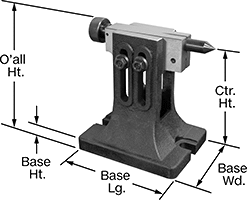

Tailstocks

Base | Mounting Slot | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ctr. Ht. | Lg. | Wd. | Ht. | Overall Ht. | No. of | Wd. | Mounting Fasteners Included | Material | Includes | Each | ||

| 3 1/4" to 4 1/4" | 5 3/8" | 3 3/4" | 4 1/8" | 4 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 0000000 | |

| 4 1/2" to 5 3/4" | 6 1/8" | 4 3/8" | 5 7/8" | 5 3/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 5 1/4" to 7 3/4" | 7 1/4" | 5 1/2" | 8 1/2" | 8" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

| 7 1/2" to 10 1/4" | 7 7/8" | 5 3/4" | 10" | 10 1/4" | 2 | 5/8" | No | Cast Iron | Standard-Point Dead Center | 0000000 | 000000 | |

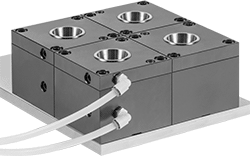

High-Density Air/Hydraulic-Operated Collet Fixtures

Collet Fixtures | Connectors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Pressure, psi | Max. Clamping Force, psi | Mounting Holes | Mounting Slots | Port | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Collet Type | For No. of Collets | For Max. Workpiece Dia. | Through-Hole Dia. | Lg. | Wd. | Ht. | Air | Hydraulic | Air-Powered | Hydraulic-Powered | Material | No. of | Thread Size | Dia. | Lg. | Wd. | No. of Ports | Pipe Size | Thread Type | Thread Gender | Includes | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

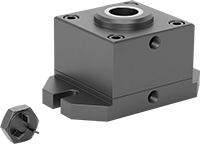

Collet Fixtures with Locking Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pull Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 4" | 4" | 3 1/2" | 150 | — | 1,125 | — | Aluminum | 4 | 3/8"-24 | — | — | — | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 0000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pull Back—Flange Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 1 | 1 1/16" | 1 3/16" | 6 1/2" | 4" | 3 1/2" | 150 | — | 1,125 | — | Aluminum | 4 | 3/8"-24 | — | 1" | 1/2" | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Collet Fixtures with Top-Locking Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Length | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1C | 1 | 1/4" | 5/16" | 1 3/4" | 1 3/4" | 1 7/16" | 250 | 750 | 180 | 545 | Aluminum | 4 | 10-24 | — | — | — | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3C | 1 | 1/2" | 5/8" | 2 1/2" | 2 1/2" | 2 3/4" | 250 | 750 | 300 | 900 | Aluminum | 4 | 1/4"-20 | — | — | — | 2 | 1/8 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5C | 3 | 1 1/16" | 1 3/16" | 8" | 3 1/2" | 3 5/16" | — | 5,000 | — | 5,500 | Aluminum | 4 | 5/16"-18 | — | — | — | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16C | 1 | 1 5/8" | 1 7/8" | 4" | 4" | 4 1/4" | 250 | 2,000 | 1,450 | 11,600 | Aluminum | 4 | 3/8"-16 | — | — | — | 2 | 1/4 | NPT | Female | Collet Wrench | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Length—Flange Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3J | 1 | 1 3/4" | 1 15/16" | 4" | 4" | 3 3/4" | — | 5,000 | — | 9,500 | Steel | 4 | — | 3/8" | — | — | 2 | 7/16 | UNF | Female | Collet Wrench | 0000000 | 00000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||