Plastic Jars

Styles C, S, and T have durable, thick walls.

Mouth | Lid | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Dia. | Ht | OD | ID | Color | Type | Material | Color | Seal Material | Autoclavable | Max. Temp., °F | Each | |

HDPE Plastic | |||||||||||||

| 2.5 gal. / 10,000 ml | 9 1/8" | 12 1/4" | 4 3/4" | 4 5/16" | Semi-Clear White | Threaded | HDPE Plastic | White | Polyethylene Foam | No | 225° | 0000000 | 000000 |

Quick-Clamp Stainless Steel Bottles

Fill these air-and liquid-tight bottles directly from your line to store, test, and ship liquids. Connect to a quick-clamp fitting (also known as tri-clamp) with the included seal and clamp to fill, then secure the contents with the lid. Bottles are 316L stainless steel, which is easy to clean and does not react to the acids and alkalies in food, or chemicals such as sulfuric acid. The extra-smooth interior is polished to prevent product buildup and inhibit bacteria growth. These bottles are engraved with lot numbers for traceability and include a material test report.

| Capacity | Dia. | Ht. | Flange OD | For Tube OD | Gauge, ga. | Interior Smoothness, Ra | Seal Material | Autoclavable | Passivation | Certification | Each | |

316L Stainless Steel Bottle and Lid | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.5 gal. / 10,000 ml | 8 3/8" | 14 1/4" | 4.682" | 4" | 16 | 10 | Silicone Rubber | Yes | Passivated | Material Certificate with Traceable Lot Number and Test Report | 0000000 | 000000000 |

Carboys

Styles A and B have a pouring spout that can be removed and stored internally.

Lid | Spout | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Dia. | Ht. | Mouth OD | Graduation Marks | Color | Type | Material | Flexibility | OD | Lg. | Autoclavable | Max. Temp., °F | Each | |

LDPE Plastic | ||||||||||||||

| 2.5 gal. | 10" | 15 1/4" | 3 1/4" | 1 gal., 1 L | Semi-Clear White | Threaded | Polypropylene Plastic | Rigid | 1 1/4" | 4 7/8" | No | 175° | 0000000 | 0000000 |

Carboys with Faucet

Open the faucet for easy dispensing.

Open the faucet for easy dispensing.

Carboys | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lid | Replacement Lids | ||||||||||||||

| Capacity, gal. | Wd. | Dp. | Ht. | Mouth OD | Graduation Marks | Color | Type | Material | Seal Material | Autoclavable | Max. Temp., °F | Each | Each | ||

Polypropylene Plastic | |||||||||||||||

| 2.5 | 9 1/2" | 9 1/2" | 14 1/4" | 3 1/2" | 1 L | Semi-Clear White | Threaded | Polypropylene Plastic | Silicone Rubber | Yes | 275° | 0000000 | 0000000 | 000000 | 000000 |

| Replacement Faucet | 000000 | Each | 000000 |

Lid | Spout | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Mouth OD | Graduation Marks | Color | Type | Material | Flexibility | OD | Lg. | Autoclavable | Max. Temp., °F | Each | |

HDPE Plastic | |||||||||||||||

| 2.5 | 7 1/4" | 10" | 14" | 1 3/4" | 1/2 gal., 2.5 L | Semi-Clear White | Threaded | HDPE Plastic | Rigid | 1 1/4" | 5" | No | 175° | 000000 | 0000000 |

Lid | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Mouth OD | Graduation Marks | Color | Type | Material | Seal Material | Autoclavable | Max. Temp., °F | Each | |

Polypropylene Plastic | |||||||||||||

| 2.5 | 6 1/2" | 14 3/4" | 9 1/2" | 1 5/8" | 1 L | Semi-Clear White | Threaded | Polypropylene Plastic | EPDM Rubber | No | 275° | 0000000 | 0000000 |

Collapsible Carboys

Flatten these carboys for convenient storage.

Lid | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Mouth OD | Color | Type | Material | Faucet Spout OD | Faucet Material | Autoclavable | Max. Temp., °F | Each | |

LDPE Plastic | |||||||||||||

| 2.5 | 9" | 9" | 9" | 1 1/2" | Clear | Threaded | LDPE Plastic | 9/16" | HDPE Plastic | No | 155° | 000000 | 000000 |

Plastic Pans

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Material | Color | Autoclavable | Max. Temp., °F | Each | |

| H | 2 1/2 gal. | 18 3/4" | 14 7/8" | 4 1/4" | 16" | 12" | Polyethylene Plastic | White | No | 170° | 0000000 | 0000000 |

Plastic Pans with Faucet

A built-in faucet allows easy draining.

Bottom Inside | Faucet Inlet | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Thread Size | Gender | Faucet Spout OD | Faucet Material | Seal Material | Autoclavable | Max. Temp., °F | Each | |

HDPE Plastic | |||||||||||||||

| 2 1/2 | 16 1/2" | 12 1/2" | 3 1/4" | 16" | 12" | White | 3/4"-16 | Male | 5/8" | Polypropylene Plastic | Rubber | No | 248° | 0000000 | 0000000 |

Food Industry Stainless Steel Pans

Metal Pans

Bottom Inside | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Gauge | Material | Autoclavable | Space Saving Features | Features | Each | ||

| C | 2 1/2 gal. | 18 1/4" | 11" | 5 1/2" | 14 1/2" | 8 1/4" | 19 | Galvanized Steel | No | Nestable | Seamless | 0000000 | 000000 |

Static-Control Fiberglass Pans

Protect sensitive equipment from electrostatic discharge.

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Color | Autoclavable | Max. Temp., °F | Space Saving Features | Surface Resistivity, ohms/sq. | Each | |

Static Dissipative | ||||||||||||

| 2 1/2 gal. | 34 1/4" | 21 3/8" | 1" | 33 1/4" | 20 5/8" | Black | Yes | 250° | Nestable | 105-109 | 00000000 | 0000000 |

Round Stainless Steel Batch Cans

Style A have clamps to hold lid down.

| Capacity, gal. | Dia. | Ht. | Bottom ID | Gauge | Appearance | Lid Type | Seal Material | Each | |

316 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 10" | 9 1/2" | 9 1/2" | 23 | Polished | Tight Fitting | Silicone Rubber | 0000000 | 0000000 |

Safety Disposal Cans for Flammable Liquids

Store leftover hazardous liquids until they can be properly discarded. The spring-loaded, self-closing cap on these cans automatically vents to relieve excess vapor pressure, and a flame arrester protects against outside ignition.

316 stainless steel cans are for liquids such as acetone, alcohol, ether, toluene, and xylene.

Galvanized steel cans are for petroleum-based liquids.

Rectangular Plastic Tanks

Store large quantities of liquid in these flat-bottomed tanks. They have vented fill caps so air can flow in and out.

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Clarity | Max. Temp., °F | UV Protection | Includes | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 14" | 9" | 6" | 1/4" | 5" | 1/2 gal. | White | Semi-Clear | 120° | UV Resistant | Vented Fill Cap | 0000000 | 000000 |

| For Fill Opening Dia. | Features | Each | |

Polypropylene Plastic | |||

|---|---|---|---|

| 5" | Vent | 0000000 | 000000 |

Wall-Mount Plastic Easy-Drain Tanks

These tanks are often used as gravity-fed dispensers.

Drain | Mounting Holes | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Pipe Size | Gender | Bottom Slope Angle | Max. Temp., °F | No. of | Dia. | Mounting Fasteners Included | UV Protection | Includes | Each | |

Polyethylene Plastic | ||||||||||||||||||

| 2 1/2 | 15" | 7" | 14" | 1/8" | 5" | 1/2 gal. | White | 3/4 NPT | Female | 30° | 120° | 4 | 3/8" | No | UV Resistant | Vented Fill Cap | 0000000 | 000000 |

| Replacement Polypropylene Plastic Fill Cap For 5" Fill Opening Dia. | 0000000 | Each | 000000 |

Safety Cans

Also known as Type I safety cans, these have a single opening for both filling and pouring. Safety cans are a safer choice than fuel cans for storing flammable liquids. They have a spring-loaded, self-closing lid; pressure-relief cap; and a flame arrester.

Powder-coated steel cans are for petroleum-based liquids. Color-coding typically indicates usage: red for gasoline, yellow for diesel, blue for kerosene, and green for other liquids.

Stainless steel cans are corrosion resistant and often used with liquids such as acetone, ether, toluene, and xylene. Style E has a steel rim at the base for added support.

Polyethylene plastic cans won't rust, dent, or pit and are for chemicals and corrosives.

Safety Cans | Rigid Plastic Pour Spouts | Flexible Steel Pour Spouts | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Cap. | Dia. | Ht. | Fill Opening Dia. | Specifications Met | Flammability Rating | Choose a Color | Each | Each | Each | |||

| C | 2 1/2 gal. | 11 3/4" | 11 1/2" | 1 5/8" | UL Listed, C-UL Listed, FM Approved, NFPA 30 | OSHA Compliant 29 CFR 1910.106 | 00000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

| Style | Cap. | Dia. | Ht. | Fill Opening Dia. | Specifications Met | Flammability Rating | Each | |

| E | 2 1/2 gal. | 11 1/4" | 9 3/4" | 1 1/2" | UL Listed, C-UL Listed, FM Approved, NFPA 30 | OSHA Compliant 29 CFR 1910.106, OSHA Compliant 29 CFR 1926.152 | 0000000 | 0000000 |

| Style | Cap. | Dia. | Ht. | Fill Opening Dia. | Specifications Met | Color | Each | |

| G | 2 1/2 gal. | 10 3/4" | 14 1/4" | 1 5/8" | UL Listed, FM Approved | Red | 0000000 | 0000000 |

Safety Cans with Built-In Spout

Also known as Type II safety cans, these have two openings—one for filling, one for pouring. Safety cans are a safer choice than fuel cans for storing flammable liquids. They have a spring-loaded, self-closing lid; pressure-relief cap; flame arrester; and a vacuum-release valve for controlled pouring.

Color-coding typically indicates usage: red for gasoline, yellow for diesel, blue for kerosene, and green for other liquids.

Style B have a steel roll bar that protects the spout, handle, and trigger during transport.

Cans | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spout | Replacement Spouts | |||||||||||||

| Style | Cap., gal. | Dia. | Ht. | Fill Opening Dia. | Lg. | OD | Flexibility | Specifications Met | UN Shipping Standard | Choose a Color | Each | Each | ||

| A | 2 1/2 | 11 1/2" | 12" | 1 1/2" | 9" | 5/8" | Flexible | C-UL Listed, UL Listed | __ | 0000000 | 0000000 | 0000000 | 000000 | |

| B | 2 1/2 | 11 3/4" | 12" | 1 1/2" | 9" | 5/8" | Flexible | FM Approved | UN1A1/Y1.2/100 | Red | 0000000 | 000000 | 0000000 | 00000 |

Liquid Nitrogen Cans

Use these cryogenic containers to store, transport, and dispense liquid nitrogen. Also known as dewars, their welded, double-aluminum walls are vacuum-insulated for maximum thermal protection.

Lid | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Dia. | Ht. | Mouth OD | Type | Material | Each | ||

Aluminum | ||||||||

| A | 2 1/2 | 10 1/2" | 21 1/2" | 2 1/4" | Loose Fitting | Plastic | 0000000 | 0000000 |

Rubber and Plastic Pails

Style G have thick walls, so they're more durable than other plastic pails.

| Capacity, gal. | Dia. | Ht. | Bottom ID | Graduation Marks | Color | Autoclavable | Max. Temp., °F | Each | |

Polyethylene Plastic | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 1/2 | 13" | 9 1/4" | 9 1/8" | 2 pt., 1 L | Semi-Clear White | No | 245° | 000000 | 0000000 |

Steel Pails

Galvanized steel is more corrosion resistant than tin-plated steel.

| Capacity | Dia. | Ht. | Bottom ID | Gauge | Autoclavable | Each | ||

Galvanized Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| B | 2 1/2 gal. | 11" | 9 1/4" | 8 1/4" | 28 | No | 000000 | 000000 |

Disposable Pails

These single-use pails are often used to mix paint.

Each | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Dia. | Ht. | Bottom ID | Graduation Marks | Color | Autoclavable | Max. Temp., °F | Each | ||

HDPE Plastic | ||||||||||

| E | 2 1/2 gal. | 10 5/8" | 9 1/2" | 8 1/4" | 32 oz., 1 qt., 1 L | Semi-Clear White | No | Not Rated | 0000000 | 00000 |

Spill-Control Trays

Styles A, B, D, and E have removable grating for easy cleaning.

Bottom Inside | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Lg. | Wd. | Ht. | Lg. | Wd. | Grating Material | Color | Grating Color | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||

| 2 1/2 gal. | 25" | 21 1/2" | 3" | 20 3/4" | 17 1/4" | Polyethylene Plastic | Yellow | Black | Stackable | Removable Grating | 00000000 | 000000 |

UN-Compliant Shipping Pails with Twist-Lock Lids

These pails have a twist-lock lid that opens and closes without tools and provides a more secure seal than a snap-lock lid. They are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Open pails for hazardous solids by squeezing the release and turning the lid.

Neoprene seals provide an extra-tight closure in the lid.

Bail handles are flexible and comfortable to hold. You only need one hand to grab them.

Pails with a drip-free pouring lip have a solid rim for a clean, controlled pour.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

| Cap., gal. | Dia. | Ht. | Color | Seal Material | Handle Type | Features | Max. Temp., °F | Shipping Standard | Lid Color | Each | |

For Shipping Hazardous Solids | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Polyethylene Plastic | |||||||||||

| 2 1/2 | 12 1/8" | 10 1/8" | White | Neoprene Rubber | Bail | Drip-Free Pouring Lip | 150° | UN1H2/Y13/S | White | 00000000 | 000000 |

Rectangular UN-Compliant Chemical-Resistant

Shipping Jugs with Tamper-Evident Seal

Prevent the absorption of harsh solvents, cleaning agents, and adhesives to safely ship hazardous liquids. These jugs have a security ring on the lid that separates when the jugs are opened. They’re also known as closed-head pails. All of these jugs are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

Jugs | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lid | Replacement Lids | |||||||||||||

| Cap., gal. | Wd. | Dp. | Ht. | Color | Material | Mouth OD | Features | Max. Temp., °F | Shipping Standard | Color | Each | Each | ||

For Shipping Hazardous Liquids | ||||||||||||||

HDPE Plastic with EPDM Rubber Seal | ||||||||||||||

| 2 1/2 | 7 5/8" | 9 1/4" | 12" | White | LDPE Plastic | 2 3/4" | Security Ring | 145° | UN3H1/Y1.8/100 | White | 00000000 | 000000 | 00000000 | 00000 |

| 2 1/2 | 8 3/8" | 9 3/8" | 11 1/2" | Black | LDPE Plastic | 2" | Security Ring | 170° | UN3H1/Y1.8/150 | Semi-Clear White | 00000000 | 00000 | 000000 | 00 |

Rectangular UN-Compliant Shipping Jugs

Also known as closed-head pails, these jugs have a small top opening. Made of HDPE, they resist chemicals and prevent the absorption of harsh solvents, cleaning agents, and adhesives to safely ship hazardous liquids. These jugs are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

Lid | Lid Knockout | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Wd. | Dp. | Ht. | Seal Material | Color | Material | Pipe Size | Gender | Thread Type | Mouth OD | Max. Temp., °F | Shipping Standard | Color | Each | |

For Shipping Hazardous Liquids | |||||||||||||||

HDPE Plastic | |||||||||||||||

| 2 1/2 | 7 3/4" | 9 1/8" | 12 1/4" | Rubber | White | Polyethylene Plastic | 3/4 | Female | NPT | 2" | 150° | UN3H1/Y1.2/100 | Semi-Clear White | 0000000 | 000000 |

UN-Compliant Rigid Plastic Shipping Jugs with Packing Kit

These jugs hold their shape as liquid is dispensed. They come with a cardboard box for protection. All are tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling. All of these jugs have threads for attaching a spigot.

To discourage tampering, use jugs with a security ring. When the jug is opened, the ring separates from the lid.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials and ensure the appropriate method for shipping.

Lid | Handle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Jugs | Cap., gal. | Color | Material | Type | Material | Color | Mouth OD | Material | Type | Features | Shipping Standard | Each | |

For Shipping Hazardous Liquids | |||||||||||||

| 2 | 2 1/2 | Semi-Clear White | HDPE Plastic | Threaded | Polypropylene Plastic | White | 2 1/2" | Plastic | Molded | Security Ring | CFR Title 49 for Packing Group II; CFR Title 49 for Packing Group III; UN4G/Y32/S | 0000000 | 000000 |

UN-Compliant Collapsible Plastic Shipping Jugs with Packing Kit

The jug inside these containers collapses as it dispenses for uninterrupted flow. The jug is protected by a cardboard box with an opening to access the jug’s spout. Use them together to ship hazardous liquids. The jug is tested to comply with United Nations regulations for packaging and shipping hazardous material over land, sea, or air. These regulations aim to prevent hazardous spills caused by accidents or rough package handling.

Note: It is the responsibility of the shipper to follow regulatory guidelines for properly packaging and labeling all hazardous materials, and ensure the appropriate method for shipping.

Lid | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Color | Material | Type | Material | Color | Mouth OD | Features | Shipping Standard | Each | |

For Shipping Hazardous Liquids | ||||||||||

| 2 1/2 | Clear | Polyethylene Plastic | Threaded | Polypropylene Plastic | White | 1 1/2" | Easy-Access Spout | CFR Title 49 for Packing Group II; CFR Title 49 for Packing Group III; UN4G/Y16/S | 000000 | 000000 |

Design-Your-Own Sealed Dispensers

Choose from a variety of containers, lids, and accessories to design a dispenser that will pour or pump contents without allowing contaminants inside. These dispensers are often used with oil and other lubricating fluids. Not for use with fuels or solvents.

Containers and lids are all interchangeable.

| Cap. | Dia. | Ht. | Mouth OD | Graduation Marks | Material | Color | Max. Temp., °F | Each | |

| 2 1/2 gal. | 9 3/4" | 13 3/4" | 4 7/8" | 1/2 qt., 0.5 L | Polyethylene Plastic | Semi-Clear White | 175° | 0000000 | 000000 |

Programmable Heated Ultrasonic Cleaners

Precisely control the cleaning process by setting the temperature and time. Heating cleaning solutions and using the degas function to remove dissolved gases increases their effectiveness. These cleaners use sound waves moving through the solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

| 10 | 11 1/2" | 9 1/2" | 6" | 15 5/8" | 15 3/4" | 14 7/8" | 40 | 469 | 120V AC | 90 | Timer, Heater, Automatic Shut-Off, Degas Function, Sleep Mode, Drain | Cover | 0000000 | 000000000 |

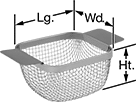

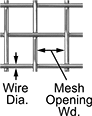

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 10, 14 1/2 | 5 | 10 3/4" | 8 1/2" | 8 1/2" | 7 1/4" | 4 7/8" | 0.222" | 0.028" | 0000000 | 0000000 |

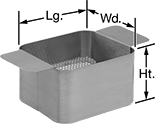

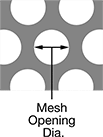

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 10, 14 1/2 | 10 | 10 1/2" | 8 1/4" | 10 1/2" | 8 1/4" | 5" | 0.156" | 0000000 | 0000000 |