Filter by

Material

DFARS Specialty Metals

RoHS

Export Control Classification Number (ECCN)

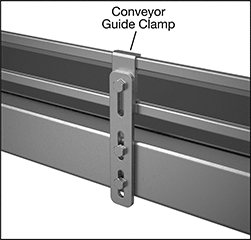

Conveyor Guide Clamps

|

|  |  |

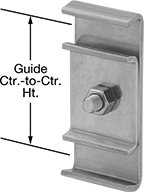

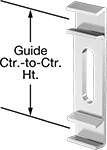

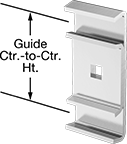

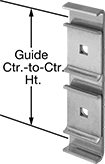

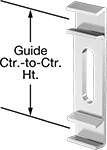

Style A | Style B | Style C |

|  |  |

Style D | Style E | Style F |

|  |  |

Style G | Style H | Style J |

|  |  |

Style K | Style L | Style M |

|  |  |

Style N | Style P | Style Q |

|  |  |

Style R | Style S | Style T |

|  |  |

Style U | Style V | Style W |

For 1 Line

|  |  |  |

Style A | Style B | Style C | Style D |

|  |  |  |

Style E | Style F | Style G | Style H |

|  |  |  |

Style J | Style K | Style L | Style M |

|  |  | |

Style N | Style P | Style Q |

Style | Wd. | Ht. | For Channel Ht. | For Rod Dia. | Thread Size | Slot Lg. | Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1.00" | 0.85" | 0.67" | — | 5/16"-18 | — | Stainless Steel | — | — | 0000000 | 00000 | |

| B | 1.25" | 0.80" | 0.67" | — | — | — | Stainless Steel | No | 5/16" | 0000000 | 00000 | |

| C | 1.50" | 1.50" | 0.67" | — | — | — | Stainless Steel | No | 5/16" | 00000000 | 0000 | |

| C | 3.00" | 1.50" | 0.67" | — | — | — | Stainless Steel | No | 5/16" | 00000000 | 00000 | |

| D | 1.50" | 1.50" | 0.67" | — | — | — | Stainless Steel | No | 5/16" | 0000000 | 0000 | |

| E | 2.30" | 0.90" | — | 1/2" | 5/16"-18 | 1.04" | Plastic | — | — | 0000000 | 00000 | |

| F | 2.30" | 1.10" | 0.67" | 1/2" | 5/16"-18 | 1.04" | Plastic | — | — | 0000000 | 00000 | |

| G | 1.06" | 1.46" | — | 1/2" | 10-32 | — | Plastic | — | — | 0000000 | 0000 | |

| H | 0.96" | 1.43" | 0.67" | — | 10-32 | — | Plastic | — | — | 0000000 | 0000 | |

| J | 0.98" | 1.14" | 0.67" | — | — | — | Plastic | No | 5/16" | 0000000 | 0000 | |

| K | 2.00" | 0.84" | 0.67" | — | — | — | Stainless Steel | — | — | 0000000 | 0000 | |

| K | 3.00" | 0.84" | 0.67" | — | — | — | Stainless Steel | — | — | 0000000 | 0000 | |

| K | 4.00" | 0.81" | 0.67" | — | — | — | Stainless Steel | — | — | 0000000 | 0000 | |

| K | 6.00" | 0.84" | 0.67" | — | — | — | Stainless Steel | — | — | 0000000 | 0000 | |

| L | 3.00" | 0.82" | 0.67" | — | 5/16"-18 | — | Stainless Steel | — | — | 00000000 | 00000 | |

| L | 4.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| L | 4.00" | 0.80" | 0.67" | — | M8 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| L | 6.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| L | 8.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| M | 3.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| M | 4.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| M | 6.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| M | 8.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| N | 3.00" | 0.90" | 0.67" | — | — | — | Stainless Steel | — | — | 0000000 | 00000 | |

| N | 4.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| N | 6.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| P | 8.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 | |

| Q | 8.00" | 0.80" | 0.67" | — | 5/16"-18 | — | Stainless Steel | Yes | — | 0000000 | 00000 |

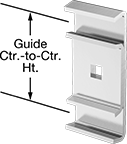

For 2 Lines

|  |  |  |

Style R | Style S | Style T | Style U |

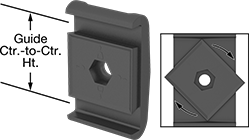

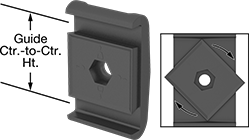

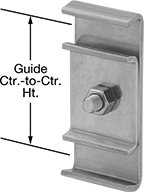

Style | Wd. | Ht. | For Channel Ht. | Guide Ctr.-to-Ctr. Ht. | For Rod Dia. | Slot Lg. | Material | Mounting Fasteners Included | Mounting Hole Dia. | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R | 2.15" | 3.60" | 0.67" | 2.76" | 1/2" | — | Plastic | No | 3/8" | 0000000 | 000000 | |

| S | 1.50" | 3.43" | 0.67" | 2.50" | — | — | Stainless Steel | Yes | 3/8" | 0000000 | 00000 | |

| S | 1.50" | 4.19" | 0.67" | 3.25" | — | — | Stainless Steel | No | 3/8" | 0000000 | 00000 | |

| T | 1.00" | 4.19" | 0.67" | 3.31" | — | 1 1/4" | Stainless Steel | No | 3/8" | 0000000 | 00000 | |

| U | 1.50" | 3.38" | 0.67" | 2.50" | — | — | Stainless Steel | No | 5/16" | 0000000 | 00000 | |

| U | 1.50" | 4.19" | 0.67" | 3.25" | — | — | Stainless Steel | No | 5/16" | 0000000 | 00000 | |

| U | 1.50" | 4.73" | 0.67" | 3.75" | — | — | Stainless Steel | No | 5/16" | 00000000 | 00000 | |

| U | 3.00" | 3.38" | 0.67" | 2.50" | — | — | Stainless Steel | No | 5/16" | 00000000 | 00000 | |

| U | 3.00" | 3.38" | 0.67" | 2.50" | — | — | Stainless Steel | No | 3/8" | 0000000 | 00000 |

Corner Brackets for Conveyor Guide Clamps

|

Wd. | Mounting Slot | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

(A) | (B) | Ht. | Angle | Wd. | Ht. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1" | 45° | 0.34" | 0.34" | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||