How to Prime Your Pump

More

How to Determine Feet of Head

More

About Process Pumps

More

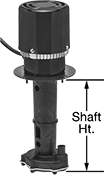

Extended-Life Immersion Circulation Pumps for Water and Coolants

A sealless construction means these pumps have few moving parts that can fail and shorten service life. The intake can be completely submerged in liquid. Pumps have a totally enclosed fan-cooled (TEFC) motor for use in dusty, dirty, and damp environments. They are gravity fed and require an elevated liquid source. Do not run dry.

12V DC pumps must be fully submerged in liquid to run.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Discharge (Female) | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Flow Rate @ 10 ft. of Head, gpm | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Electrical Connection Type | hp | Current, A | Intake Connection Type | Tube Connection Type | For Tube OD | Dia. | Ht. | Shaft Ht. | Each | |

120V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||

| 11 | 7 | 13 | 5 | 70 | 50° to 150° | Plug | 1/15 | 2.4 | Screened Inlet | Push to Connect | 5/8" | 5" | 13" | 8 1/8" | 0000000 | 0000000 |

| 11 | 7 | 13 | 5 | 70 | 50° to 150° | Plug | 1/15 | 2.4 | Screened Inlet | Push to Connect | 5/8" | 5" | 15" | 10 1/2" | 0000000 | 000000 |

240V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||

| 11 | 7 | 13 | 5 | 70 | 50° to 150° | Plug | 1/15 | 1.2 | Screened Inlet | Push to Connect | 5/8" | 5" | 10" | 5 1/8" | 0000000 | 000000 |

| 11 | 7 | 13 | 5 | 70 | 50° to 150° | Plug | 1/15 | 1.2 | Screened Inlet | Push to Connect | 5/8" | 5" | 13" | 8 1/8" | 0000000 | 000000 |

| 11 | 7 | 13 | 5 | 70 | 50° to 150° | Plug | 1/15 | 1.2 | Screened Inlet | Push to Connect | 5/8" | 5" | 15" | 10 1/2" | 0000000 | 000000 |

| Replacement Impeller | 0000000 | Each | 0000000 |

Intake | Discharge | Overall | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | Flow Rate @ 10 ft. of Head, gpm | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | Temp. Range, °F | Electrical Connection Type | hp | Current | Pipe Size | Gender | Thread Type | Pipe Size | Gender | Thread Type | Lg. | Wd. | Ht. | Each | |

12V DC—Without Thermal Overload Protection | |||||||||||||||||||

| 2.7 | 0.5 | 11 | 50 | 5 | 32° to 120° | Hardwire | Subfractional | 0.9A | 1/4 | Male | NPT | 1/4 | Male | NPT | 4 15/16" | 2 1/4" | 3 1/4" | 0000000 | 0000000 |

24V DC—Without Thermal Overload Protection | |||||||||||||||||||

| 2.7 | 0.5 | 11 | 50 | 5 | 32° to 190° | Hardwire | Subfractional | 0.5A | 1/4 | Male | NPT | 1/4 | Male | NPT | 4 15/16" | 2 1/4" | 3 1/4" | 0000000 | 000000 |

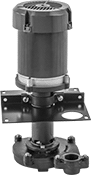

Immersion Circulation Pumps for Coolants

Commonly used in machine tool coolant tanks, these pumps have an intake that can be completely submerged in liquid. A universal mounting plate fits machine tools from manufacturers such as Fuji, Mitsubishi, Toshiba, Hitachi, and Yasukawa. Motor is totally enclosed with sealed bearings for use in dusty, dirty, and damp environments. Pumps are gravity fed and require an elevated liquid source. They can run dry.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Pumps | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Discharge (NPT) | Overall | Replacement Impellers | |||||||||||||||||||

| Max. Flow Rate, gpm | @ 10 ft. of Head | @ 20 ft. of Head | @ 30 ft. of Head | @ 40 ft. of Head | @ 50 ft. of Head | @ 60 ft. of Head | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | hp | Current, A | Intake Connection Type | Pipe Size | Gender | Lg. | Wd. | Ht. | Shaft Ht. | Each | Each | ||

120/240V AC, Single Phase—Without Thermal Overload Protection | ||||||||||||||||||||||

Hardwire | ||||||||||||||||||||||

| 10 | 5 | __ | __ | __ | __ | __ | 13 | 5 | 90 | 1/8 | 0.7/0.4 | Open Inlet | 3/8 | Female | 5 1/2" | 3 1/2" | 11 3/4" | 6" | 00000000 | 0000000 | 0000000 | 000000 |

| 20 | 20 | 14 | 5 | __ | __ | __ | 33 | 13 | 90 | 1/4 | 3/1.5 | Open Inlet | 1/2 | Female | 7 1/2" | 5" | 14 7/8" | 7 1/16" | 00000000 | 000000 | 0000000 | 00000 |

| 35 | 34 | 27 | 18 | 5 | __ | __ | 42 | 18 | 90 | 1/2 | 6/3 | Open Inlet | 3/4 | Female | 7 1/2" | 5 9/16" | 18 19/32" | 9 7/16" | 00000000 | 000000 | 000000 | 00 |

240/460V AC, Three Phase—Without Thermal Overload Protection | ||||||||||||||||||||||

Hardwire | ||||||||||||||||||||||

| 10 | 5 | __ | __ | __ | __ | __ | 13 | 5 | 90 | 1/8 | 0.3/0.2 | Open Inlet | 3/8 | Female | 5 1/2" | 3 1/2" | 11 3/4" | 6" | 00000000 | 000000 | 0000000 | 00000 |

| 20 | 20 | 14 | 5 | __ | __ | __ | 33 | 13 | 90 | 1/4 | 0.9/0.6 | Open Inlet | 1/2 | Female | 7 1/2" | 5" | 14 7/8" | 7 1/16" | 00000000 | 000000 | 0000000 | 00000 |

| 35 | 34 | 27 | 18 | 5 | __ | __ | 42 | 18 | 90 | 1/2 | 2/1.4 | Open Inlet | 3/4 | Female | 7 1/2" | 5 9/16" | 18 19/32" | 9 7/16" | 00000000 | 000000 | 0000000 | 00000 |

| 45 | 52 | 45 | 35 | 25 | 10 | __ | 55 | 23 | 90 | 3/4 | 2.6/1.6 | Open Inlet | 1 | Female | 8 3/8" | 6" | 20 29/32" | 11 15/32" | 00000000 | 00000000 | 0000000 | 000000 |

| 50 | __ | 50 | 40 | 30 | 18 | 1 | 60 | 25 | 90 | 1 | 3.2/2 | Open Inlet | 1 | Female | 8 3/8" | 6" | 22 3/32" | 11 15/32" | 00000000 | 00000000 | 0000000 | 000000 |

Heavy Duty Immersion Circulation Pumps for Water and Coolants

The durable motor and impeller can handle dirty coolant and machine lubricants with solids up to 1/4" diameter. These pumps have an intake that can be completely submerged in liquid. The motor is totally enclosed fan-cooled (TEFC) for use in dusty, dirty, and damp environments. Pumps are gravity fed and require an elevated liquid source. Do not run dry.

Note: If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Flow Rate, gpm | Discharge | Overall | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Flow Rate, gpm | @ 10 ft. of Head | @ 20 ft. of Head | Max. ft. of Head | Max. Pressure | Max. Viscosity, cP | Temp. Range, °F | hp | Current, A | Intake Connection Type | Pipe Size | Gender | Thread Type | Lg. | Wd. | Ht. | Shaft Ht. | Each | ||

208-240/460V AC, Three Phase—Without Thermal Overload Protection | |||||||||||||||||||

Hardwire | |||||||||||||||||||

| 1 | 67 | 34 | __ | 17 | Not Rated | 108 | 40° to 200° | 1/3 | 2/1 | Open Inlet | 1 1/4 | Female | NPT | 8 3/4" | 8 3/8" | 20 5/8" | 11 3/4" | 0000000 | 0000000 |

| 2 | 67 | 40 | __ | 21 | Not Rated | 108 | 40° to 200° | 1/3 | 2/1 | Open Inlet | 1 1/4 | Female | NPT | 8 3/4" | 8 3/8" | 18 7/8" | 9 3/4" | 0000000 | 000000 |

| 3 | 67 | __ | 40 | 32 | Not Rated | 108 | 40° to 200° | 3/4 | 3/2 | Open Inlet | 1 1/2 | Female | NPT | 10 3/4" | 9 1/4" | 19 3/4" | 9 7/8" | 0000000 | 000000 |

| 4 | 67 | __ | 40 | 32 | Not Rated | 108 | 40° to 200° | 3/4 | 3/2 | Open Inlet | 1 1/2 | Female | NPT | 10 3/4" | 9 1/4" | 25 3/4" | 15 7/8" | 0000000 | 000000 |

Remote-Mount Circulation Pumps for Water and Coolants

Use when space is limited—these pumps connect to a pipe coming from your tank so you can place the pump in another location. Mount above or below the liquid level. Pumps are self-priming after you fill the pump chamber with liquid. As liquid in the chamber is expelled, a suction force is created which allows the pump to draw liquid upward.

Note: Pumps must be filled with liquid before use. They need a constant flow of liquid and cannot run dry. If flow control is needed, place valves or reducers on the discharge side; never restrict the inlet of a pump with a valve or reducer.

Pumps | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flow Rate, gpm | Intake (NPT) | Discharge (NPT) | Overall | Replacement Impellers | ||||||||||||||||||

| Max. Flow Rate, gpm | @ 10 ft. of Head | @ 20 ft. of Head | @ 30 ft. of Head | @ 40 ft. of Head | @ 50 ft. of Head | @ 60 ft. of Head | Max. ft. of Head | Max. Pressure, psi | Max. Viscosity, cP | hp | Current, A | Pipe Size | Gender | Pipe Size | Gender | Lg. | Wd. | Ht. | Each | Each | ||

120/240V AC, Single Phase—Without Thermal Overload Protection | ||||||||||||||||||||||

Hardwire | ||||||||||||||||||||||

| 10 | 5 | __ | __ | __ | __ | __ | 13 | 5 | 90 | 1/8 | 0.7/0.4 | 3/8 | Female | 3/8 | Female | 6 1/2" | 5 1/2" | 6 7/8" | 00000000 | 0000000 | 0000000 | 000000 |

| 20 | 20 | 14 | __ | __ | __ | __ | 33 | 13 | 90 | 1/4 | 3/1.5 | 3/4 | Female | 3/4 | Female | 8" | 7 1/16" | 9 5/32" | 00000000 | 000000 | 000000 | 00 |

| 32 | __ | 27 | 18 | 5 | __ | __ | 42 | 18 | 90 | 1/2 | 6/3 | 3/4 | Female | 3/4 | Female | 8 3/8" | 7 1/4" | 11 3/4" | 00000000 | 00000000 | 0000000 | 00000 |

240/460V AC, Three Phase—Without Thermal Overload Protection | ||||||||||||||||||||||

Hardwire | ||||||||||||||||||||||

| 10 | 5 | __ | __ | __ | __ | __ | 13 | 5 | 90 | 1/8 | 0.3/0.2 | 3/8 | Female | 3/8 | Female | 6 1/2" | 5 1/2" | 6 7/8" | 00000000 | 000000 | 0000000 | 00000 |

| 20 | 20 | 14 | __ | __ | __ | __ | 33 | 13 | 90 | 1/4 | 0.9/0.6 | 3/4 | Female | 3/4 | Female | 8" | 7 1/16" | 9 5/32" | 00000000 | 000000 | 0000000 | 00000 |

| 32 | __ | 27 | 18 | 5 | __ | __ | 42 | 18 | 90 | 1/2 | 2/1.4 | 3/4 | Female | 3/4 | Female | 8 3/8" | 7 1/4" | 11 3/4" | 00000000 | 00000000 | 0000000 | 00000 |

| 43 | __ | __ | 35 | 25 | 10 | __ | 55 | 23 | 90 | 3/4 | 2.6/1.6 | 1 | Female | 1 | Female | 8 5/8" | 8 1/16" | 12 1/4" | 00000000 | 00000000 | 0000000 | 000000 |

| 48 | __ | __ | 40 | 30 | 18 | 1 | 60 | 25 | 90 | 1 | 3.2/2 | 1 | Female | 1 | Female | 8 1/2" | 8" | 13 31/32" | 00000000 | 00000000 | 0000000 | 000000 |