How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

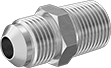

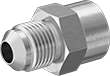

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

Metric and UN/UNF (Straight) threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 1/8" and 1" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | Each | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Specifications Met | 1-9 | 10-49 | 50-Up | |

NPTF Threads | ||||||||||||

| 3/4" | 0.035" | 1/2 | __ | __ | Brass | __ | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 000000 | 000000 | 000000 |

| 3/4" | 0.035" | 3/4 | __ | __ | Brass | __ | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 | 00000 | 00000 |

Metric Threads | ||||||||||||

| 3/4" | 0.035" | __ | M27 | 2 | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 | 00000 | 00000 |

UN/UNF (SAE Straight) Threads | ||||||||||||

| 3/4" | 0.035" | __ | 3/4"-16 | __ | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 | 00000 | 00000 |

| 3/4" | 0.035" | __ | 1 1/16"-12 | __ | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 | 00000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 5/8" and 3/4" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | 1-9 | 10-49 | 50-Up | |

NPTF Threads | |||||||||

| 3/4" | 0.035" | 3/4 | Brass | 550 psi @ 73° F | SAE J512, SAE J513 | 000000000 | 000000 | 000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: See table

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

| 3/4" | 0.035" | Brass | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

- For Use With:

Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water - Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Thread Size | Material | Gasket Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

NPTF Threads | ||||||||||

| 3/4" | 0.035" | 1/2 | __ | Brass | __ | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

| 3/4" | 0.035" | 3/4 | __ | Brass | __ | 550 psi @ 72° F | 000000000 | 00000 | 00000 | 00000 |

UN/UNF (SAE Straight) Threads | ||||||||||

| 3/4" | 0.035" | __ | 1 1/16"-12 | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | 000000000 | 00000 | 00000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

Fittings that swivel until tightened rotate 360° for easy installation.

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Thread Size | Material | Gasket Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

UN/UNF (SAE Straight) Threads | ||||||||

| 3/4" | 1 1/16"-14 | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

| 3/4" | 0.035" | Brass | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Thread Size | Material | Gasket Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

NPTF Threads | ||||||||||

| 3/4" | 0.035" | 1/2 | __ | Brass | __ | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

UN/UNF (SAE Straight) Threads | ||||||||||

| 3/4" | 0.035" | __ | 3/4"-16 | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | 000000000 | 00000 | 00000 | 00000 |

| 3/4" | 0.035" | __ | 1 1/16"-12 | Brass | Fluoroelastomer Rubber | 550 psi @ 72° F | 00000000 | 00000 | 00000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

For Tube | Each | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | 1-9 | 10-49 | 50-Up | |

| 3/4" | 0.035" | Brass | 550 psi @ 72° F | 000000000 | 000000 | 000000 | 000000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

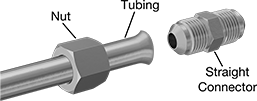

Nuts for 45° Flared Fittings for Copper and Brass Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

Use these nuts with 45° flared tube fittings to provide a tight metal-to-metal seal on flared copper and brass tubing. Nuts are brass for good corrosion resistance. They don’t require a sleeve, which makes for a fast, convenient installation.

Long nuts support more of the tube’s surface area than short nuts for a strong grip in high-vibration applications.

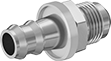

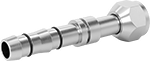

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a 45° flared end are also known as refrigeration and SAE fittings.The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 00000000 | 0000000 |

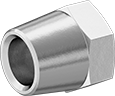

Refrigerant Hose Fittings

- Maximum Pressure: 500 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -40° to 280° F

- Compatible With: Danfoss EZ Clip

- All Fittings Swivel Until Tightened

- Specifications Met: SAE J2064, SAE J3062

- Compatible Hose: Refrigerant Hose

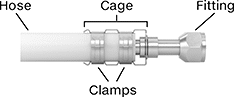

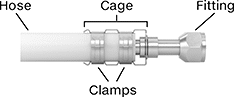

No need for expensive crimping tools—these fittings make air conditioning and refrigeration assemblies with clamps. Instead of a crimper, they use two clamps that you tighten against a cage on your fitting with pliers. Both fitting ends swivel until tightened, so you don't have to rotate the entire hose during installation. The cage and clamps stretch out after use, so they shouldn't be used again.

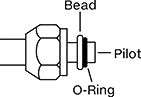

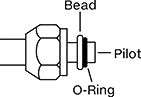

Fittings with an O-ring pilot create a leak-tight seal, so they’re often used in commercial and vehicle air conditioning systems. When you screw the fitting onto your tube, the bead and the pilot squeeze the O-ring, which fills in any gaps. The pilot also helps guide your hose onto the fitting, making it easy to properly align and secure the connection.

Dash Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID | For Hose | Fitting | Thread Size | Bead OD | Pilot Lg. | Includes | Each | |

Zinc-Plated Steel | ||||||||

| 5/8" | 12 | 12 | 1 1/16"-14 | 0.91" | 0.19" | 2 Clamps, Cage, O-Ring | 0000000 | 000000 |

Dash Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID | For Hose | Fitting | Thread Size | Bead OD | Pilot Lg. | Includes | Each | |

Zinc-Plated Steel | ||||||||

| 5/8" | 12 | 12 | 1 1/16"-14 | 0.91" | 0.19" | 2 Clamps, Cage, O-Ring | 0000000 | 000000 |

Jaw | |||||||

|---|---|---|---|---|---|---|---|

| Overall Lg. | Grip Style | Opening Style | Texture | Material | Tip Type | Each | |

Pinch Clamp Pliers—Straight Jaw | |||||||

| 6 7/8" | Cushion | Spring Assisted | Smooth | Steel | Fixed | 0000000 | 0000000 |

Band | |||||||

|---|---|---|---|---|---|---|---|

| For Hose ID | Dash Size | Wd. | Thick. | Reusable | Includes | Each | |

304 Stainless Steel Clamps with 301 Stainless Steel Cage | |||||||

Single Pinch | |||||||

| 5/8" | 12 | 5/16" | 0.024" | No | 2 Clamps, Cage | 0000000 | 00000 |

Band | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | For OD | Dash Size | Wd. | Thick. | Reusable | Number of Pieces | Includes | Each | |

304 Stainless Steel Clamps with 301 Stainless Steel Cages | |||||||||

Single Pinch | |||||||||

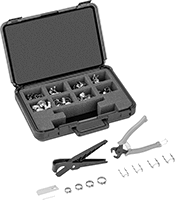

| 5/16" to 5/8" | 0.6" to 0.99" | 06, 08, 10, 12 | 5/16" | 0.024" | No | 122 | Cages with 5/16" band width for 5/16" hose ID (10 each) Clamps with 5/16" band width, .32" clamp ID (20 each) Cages with 5/16" band width for 13/32" hose ID (10 each) Clamps with 5/16" band width, .42" clamp ID (20 each) Cages with 5/16" band width for 1/2" hose ID (10 each) Clamps with 5/16" band width, .52" clamp ID (20 each) Cages with 5/16" band width for 5/8" hose ID (10 each) Clamps with 5/16" band width, .62" clamp ID (20 each) Pinch Clamp Pliers Hose Cutter | 0000000 | 0000000 |