How to Measure Threaded Pipe Size

More

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Selecting Compatible Lead Screws and Nuts

More

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance. BSPP and metric male threads have either a gasket or a gasket and washer to prevent leaks.

- For Use With:

NPTF: Hydraulic Fluid, Oil, Steam, Water

BSPP and Metric: Hydraulic Fluid, Oil, Water - Specifications Met:

NPTF: ASTM A479

Metric: DIN 7631, ISO 9974

BSPP: ISO 1179, ISO 8434-6

316 Stainless Steel | ||||

|---|---|---|---|---|

| Thread Size | Drive Size | Max. Pressure | Each | |

Metric Male | ||||

| M26 × 1.5 mm | 12 mm | 5,800 psi @ 72° F | 00000000 | 000000 |

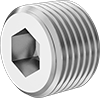

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Plugs with copper washer form a tight seal to prevent leaks. Also known as a crush washer, the washer compresses and deforms to fill gaps when tightened. Because it loses its shape when compressed, it’s not reusable. Made of copper, the washer resists rust. These plugs meet either DIN 908, DIN 909, or DIN 910, international standards for pipe plug dimensions.

- For Use With:

NPT, BSPP, and Metric: Air, Natural Gas, Oil, Steam, Water

NPTF: Air, Natural Gas, Steam, Water - Pressure Class:

NPT: 150 - Specifications Met:

BSPP and Metric: DIN 908 - Pipe Nipples and Pipe:

NPT: Use Schedule 40 steel

| Thread Size | Drive Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

Metric Male with Copper Washer | ||||||

|---|---|---|---|---|---|---|

| M26 × 1.5 mm | 12 mm | Not Rated | Not Rated | Steel | 000000000 | 00000 |

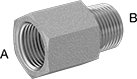

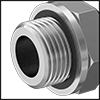

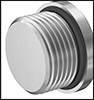

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks.

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Thread Size (A) | Dash Size (A) | Pipe Size (B) | Thread Size (B) | Dash Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPT Female × Metric Male | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4 | __ | 12 | __ | M26 × 1.5 mm | __ | 3,000 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 6149, ISO 9974 | 00000000 | 000000 |

Metric Female × NPT Male | |||||||||||

| __ | M26 × 1.5 mm | __ | 3/4 | __ | 12 | 3,500 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Oil, Water | ASME B1.20.3, DIN 7631, ISO 6149, ISO 9974 | 00000000 | 00000 |

Male Threads

with Gasket

- For Use With:

NPTF and UN/UNF (SAE Straight): Air, Hydraulic Fluid, Water

Metric, BSPP and BSPT: Air, Hydraulic Fluid, Oil, Water - Specifications Met: See table

| Thread Size | Drive Size | Max. Pressure | Material | Specifications Met | Each | |

Metric Male | ||||||

|---|---|---|---|---|---|---|

| M26 × 1.5 mm | 14 mm | 5,600 psi @ 72° F | Zinc Plated Steel | DIN 7631, ISO 9974 | 00000000 | 000000 |

Male Threads with

Gasket and Washer

- For Use With: See table

- Specifications Met: See table

| Thread Size | Plug Construction | Max. Pressure | Material | For Use With | Specifications Met | Each | |

Metric Male | |||||||

|---|---|---|---|---|---|---|---|

| M26 × 1.5 mm | Solid | 5,600 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Oil, Water | DIN 7631, ISO 6149, ISO 9974 | 00000000 | 000000 |

- Temperature Range: -20° to 230° F

| For Thread Size | Gasket Material | Thickness | Each | |

For Metric Male | ||||

|---|---|---|---|---|

| M26 | Buna-N Rubber | 2.5mm | 00000000 | 00000 |

High-Pressure Plated Brass Threaded Pipe Fittings

The plating on these brass fittings creates a shiny finish and provides extra protection in corrosive environments. Fittings have the strength to handle high-pressure applications.

Nickel-plated brass fittings provide better corrosion resistance than unplated brass fittings.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall or panel to create an inlet or outlet.

- For Use With: Air, Natural Gas, Oil, Water

Nickel-Plated Brass | |||||

|---|---|---|---|---|---|

| Pipe Size | Thread Size | For Max. Wall Thick. | Max. Pressure | Each | |

BSPP Female × Metric Male | |||||

| 3/8 | M26 × 1.5 mm | 0.591" | 1,080 psi @ 72° F | 00000000 | 000000 |

Low-Pressure Aluminum Threaded Pipe Fittings

In addition to being lightweight, these aluminum fittings offer good corrosion resistance. Use them in low-pressure flow applications. To prevent cracking, do not tighten more than a 1/4-turn past hand tight.

DIN 3852 fittings meet DIN standards for mating surface outer diameter. They have a Buna-N rubber gasket that resists grease, hydraulic oil, and motor oil—plus mild chemicals and water. The gasket stays in a groove undercut in the mating face, which prevents it from dropping out and from extruding when fittings are tightened. Black anodized and powder-coated fittings have a decorative matte black finish.

The contact surface on fittings with a flange extends beyond the external hex drive.

Male Threads

with Gasket

- For Use With: Air, Oil, Water

- Specifications Met: DIN 3852

- Pipe Nipples and Pipe: Use aluminum

Black Anodized Aluminum Alloy | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Thread Pitch, mm | Drive Size | Plug Construction | Max. Pressure | Each | |

Metric Male | |||||||

| 3/4 | M26 | 1.5 | 27 mm | Solid | Not Rated | 00000000 | 000000 |

Metric Lead Screws and Nuts

Found in hand-powered clamps, vises, grates, doors, and work tables, lead screws and nuts have broad, square threads that are well suited for quick assembly, high clamping forces, and lifting and lowering heavy objects. To ensure compatibility, please select components that have the same thread direction, size, pitch, and number of thread starts. Class 7e and 7H components are compatible.

932 bearing bronze components are more wear resistant than brass components. They have good machinability and fair corrosion resistance.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

Flange nuts move objects along the length of a lead screw. They have a wide machinable flange for custom mounting.

Flange | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Ht., mm | Dia., mm | Dia., mm | Thick., mm | No. of Thread Starts | Speed Ratio | Travel Distance per Turn, mm | Thread Fit | Hardness | Each | |

932 Bearing Bronze | ||||||||||||

| M26 | 5 | 46 | 38 | 62 | 14 | 1 | 1:1 | 5 | 7H | Not Rated | 000000000 | 0000000 |

Hex nuts fasten and position lead screw components.

| Thread Size | Thread Pitch, mm | Ht., mm | Wd., mm | No. of Thread Starts | Speed Ratio | Travel Distance per Turn, mm | Thread Fit | Fastener Strength Grade/Class | Hardness | Each | |

Carbon Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M26 | 5 | 25.4 | 41.3 | 1 | 1:1 | 5 | 7H | Grade 2 | Not Rated | 000000000 | 000000 |