Filter by

Hole Shape

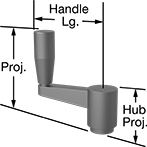

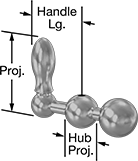

Handle Length

Hub Projection

Grip Material

Grip Height

Projection

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Unthreaded Through-Hole-Mount Crank Handles

|  |  |  |

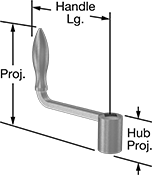

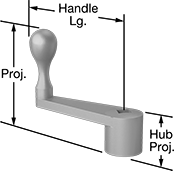

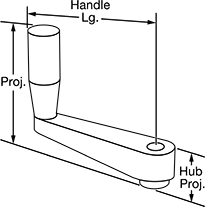

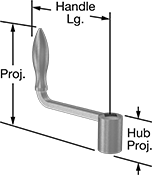

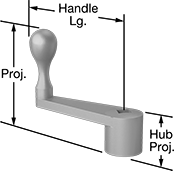

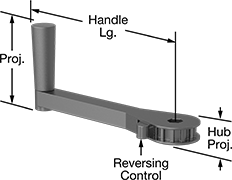

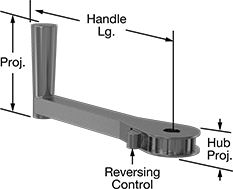

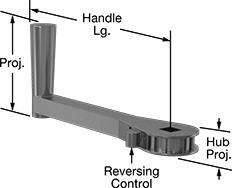

Round Hole Style 1 | Round Hole Style 2 | Round Hole Style 3 | Round Hole Style 4 |

|  |  |  |

Round Hole Style 5 | Round Hole Style 6 | Round Hole Style 7 | Round Hole Style 8 |

|  | ||

Square Hole Style 9 | Square Hole Style 10 |

Round Hole

|  |  |  |

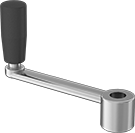

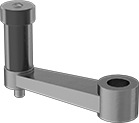

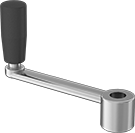

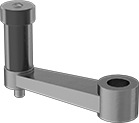

Style 1 | Style 2 | Style 3 | Style 4 |

|  |  |  |

Style 5 | Style 6 | Style 7 | Style 8 |

|

Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Handle Lg. | Projection | Hub Projection | Hole Dia. | Ht. | Material | Color | Temperature Range | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip with Offset Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 100 mm | 128 mm | 28 mm | 10 mm | 80 mm | Zinc-Plated Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 125 mm | 141 mm | 34 mm | 10 mm | 86 mm | Zinc-Plated Steel | — | — | — | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 160 mm | 162 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 200 mm | 196 mm | 44 mm | 17 mm | 118 mm | Zinc-Plated Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 315 mm | 248 mm | 54 mm | 20 mm | 143 mm | Zinc-Plated Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 80 mm | 92 mm | 24 mm | 8 mm | 74 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

302 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3 5/16" | 3 3/8" | 3/4" | 1/2" | 3" | Stainless Steel | — | — | 1/8" Diameter Set Screw Starting Hole | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 4 7/8" | 3 15/16" | 7/8" | 5/8" | 3 1/2" | Stainless Steel | — | — | 3/16" Diameter Set Screw Starting Hole | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Offset Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 80 mm | 112 mm | 24 mm | 8 mm | 74 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 125 mm | 141 mm | 34 mm | 10 mm | 86 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 160 mm | 162 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 315 mm | 248 mm | 54 mm | 20 mm | 143 mm | Zinc-Plated Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 100 mm | 101 mm | 28 mm | 10 mm | 80 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 mm | 116 mm | 34 mm | 10 mm | 90 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 mm | 126 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 250 mm | 163 mm | 48 mm | 17 mm | 127 mm | Zinc-Plated Steel | — | — | — | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Painted Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 1/2" | 1 21/32" | 11/16" | 5/16" | 1 5/16" | Phenolic | Black | 0° F to 350° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 7/8" | 2 1/8" | 13/16" | 3/8" | 1 11/16" | Phenolic | Black | 0° F to 350° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 1/2" | 3" | 15/16" | 3/8" | 2 1/2" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 3/8" | 3 3/4" | 1 1/8" | 1/2" | 3 1/8" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 4 19/32" | 1 5/16" | 5/8" | 3 25/32" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 4 3/4" | 1 1/2" | 3/4" | 3 29/32" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 5/32" | 3 17/32" | 1 7/16" | 3/8" | 2 9/16" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 15/16" | 4 11/32" | 1 9/16" | 1/2" | 3 9/32" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 1/8" | 5 23/32" | 1 15/16" | 5/8" | 4 1/16" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 6 5/16" | 5 29/32" | 2 3/16" | 3/4" | 4 1/8" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 80 mm | 86 mm | 36 mm | 10 mm | 65 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 100 mm | 106 mm | 40 mm | 12 mm | 84 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 130 mm | 135 mm | 49 mm | 14 mm | 109 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 31/32" | 1 29/32" | 11/16" | 3/8" | 1 1/2" | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 17/32" | 2 9/16" | 13/16" | 1/2" | 2 1/8" | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/32" | 3 5/32" | 15/16" | 1/2" | 2 5/8" | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/16" | 3 15/16" | 1 1/8" | 1/2" | 3 1/4" | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 50 mm | 49 mm | 18 mm | 8 mm | 39 mm | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 64 mm | 66 mm | 20 mm | 10 mm | 55 mm | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 80 mm | 81 mm | 24 mm | 10 mm | 67 mm | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 100 mm | 100 mm | 28 mm | 12 mm | 83 mm | Polypropylene | Black | Not Rated to 175° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 1/8" | 2 5/8" | 7/8" | 1/2" | 1 3/4" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 15/16" | 3 3/16" | 1" | 1/2" | 2 1/2" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 4 15/16" | 3 7/8" | 1 1/8" | 5/8" | 2 13/16" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6 5/16" | 4 1/16" | 1 1/4" | 3/4" | 3 5/32" | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 80 mm | 67 mm | 22 mm | 10 mm | 52 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 100 mm | 81 mm | 26 mm | 12 mm | 63 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 125 mm | 99 mm | 28 mm | 14 mm | 80 mm | Phenolic | Black | Not Rated to 230° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 1/4" | 5" | 1 1/8" | 1/2" | 3 23/32" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 6 9/32" | 1 5/16" | 5/8" | 4 17/32" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 6 13/32" | 1 1/2" | 3/4" | 4 21/32" | Phenolic | Black | 0° F to 210° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Indexing Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 75 mm | 90 mm | 24 mm | 16 mm | 90 mm | Black-Oxide Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 110 mm | 90 mm | 30 mm | 20 mm | 90 mm | Black-Oxide Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 165 mm | 90 mm | 36 mm | 24 mm | 90 mm | Black-Oxide Steel | — | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Recessed-Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 5/32" | 2 11/16" | 1" | 1/2" | 2 17/32" | Nylon | Black | Not Rated to 190° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 15/16" | 3 7/16" | 1 3/16" | 1/2" | 3 3/16" | Nylon | Black | Not Rated to 190° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4 29/32" | 4 15/32" | 1 7/16" | 5/8" | 4 1/32" | Nylon | Black | Not Rated to 190° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 80 mm | 69 mm | 26 mm | 10 mm | 65 mm | Nylon | Black | Not Rated to 190° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 125 mm | 113 mm | 37 mm | 14 mm | 103 mm | Nylon | Black | Not Rated to 190° F | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

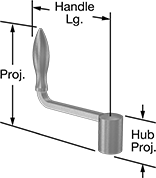

Square Hole

|  |

Style 9 | Style 10 |

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Handle Lg. | Projection | Dia. | Projection | Hole Wd. | Ht. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 2 5/8" | 3 5/8" | 1" | 1 1/4" | 1/2" | 2 7/32" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 4" | 4 5/16" | 1 1/16" | 1 5/16" | 1/2" | 2 1/2" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 4 1/2" | 4 1/2" | 1 1/4" | 1 3/8" | 9/16" | 2 11/16" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 5 1/2" | 4 15/16" | 1 1/4" | 1 13/16" | 5/8" | 2 7/8" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 6 1/2" | 5 1/8" | 1 1/4" | 1 15/16" | 11/16" | 2 15/16" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 8" | 5 7/16" | 1 3/8" | 2 1/16" | 3/4" | 2 7/8" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 9" | 6 1/16" | 1 9/16" | 2 7/16" | 7/8" | 3 3/16" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 11" | 7" | 1 3/4" | 3" | 1" | 3 1/2" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 4 7/16" | 3 7/8" | — | 1 3/8" | 9/16" | 2 7/8" | Chrome-Plated Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5 9/16" | 5 3/8" | — | 1 13/16" | 5/8" | 3 31/32" | Chrome-Plated Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 7 5/8" | 5 15/16" | — | 2 1/16" | 3/4" | 4 7/32" | Chrome-Plated Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ratcheting Unthreaded Through-Hole-Mount Crank Handles

|  |

Hex Hole | Round Hole with Keyway |

| |

Square Hole |

Square Hole |

Hex Hole |

Round Hole with Keyway |

Keyway | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Hub Projection | Hole Wd. | Hole Dia. | Wd. | Dp. | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hex Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1 1/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Hole with Keyway | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 1/2" | 1/8" | 1/16" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 5/8" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 3/4" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 1" | 1/4" | 1/8" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 3/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Position Threaded-Hole-Mount Crank Handles

Thread | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Handle Lg. | Projection | Hub Projection | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 7/16" | 2 1/16" | 2 19/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 27/32" | 2 1/16" | 3" | Nylon | Black | 15° F to 245° F | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Balanced Machinable-Hub-Mount Crank Handles

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Dia. | Projection | Ht. | Material | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 9/32" | 7/8" | 7/8" | 2 1/8" | Steel | 1/4" Diameter Set Screw Starting Hole | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 21/32" | 1" | 1" | 2 15/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 4 1/16" | 1 3/8" | 1 3/8" | 3 3/4" | Steel | 1/4" Diameter Set Screw Starting Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2 15/16" | 1" | 1" | 2 23/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 29/32" | 4 9/32" | 1 3/8" | 1 3/8" | 3 31/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machinable-Hub-Mount Crank Handles

|

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Dia. | Projection | Ht. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018 Low-Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/8" | 3 5/8" | 1" | 1 1/4" | 2 7/32" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 4 5/16" | 1 1/16" | 1 5/16" | 2 1/2" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 4 1/2" | 1 1/4" | 1 3/8" | 2 11/16" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 4 15/16" | 1 1/4" | 1 13/16" | 2 7/8" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/2" | 5 1/8" | 1 1/4" | 1 15/16" | 2 15/16" | Steel | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 5 7/16" | 1 3/8" | 2 1/16" | 2 7/8" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 6 1/16" | 1 9/16" | 2 7/16" | 3 3/16" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 7" | 1 3/4" | 3" | 3 1/2" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||