Filter by

Material

Mount Type

Washer Type

Profile Shape

Countersink Angle

Texture

Shear Capacity per Mount

System of Measurement

Capacity per Mount

Export Control Classification Number (ECCN)

DFARS Specialty Metals

RoHS

Performance

Maximum Temperature

For Use Outdoors

Finishing Washers

Flat and oval head screws sit flush within these washers for a neat, finished appearance.

Flanged Finishing Washers

|

18-8 Stainless Steel—18-8 stainless steel washers have good chemical resistance and may be mildly magnetic.

Other Finishing Washers

|

18-8 Stainless Steel—18-8 stainless steel washers have good chemical resistance and may be mildly magnetic.

316 Stainless Steel—316 stainless steel washers have excellent resistance to chemicals and salt water. They may be mildly magnetic.

For Screw Size | ID | OD | Overall Ht. | Countersink Angle | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.150" | 0.375" | 0.110" | 82° | 100 | 98466A005 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.180" | 0.438" | 0.110" | 82° | 100 | 98466A007 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.210" | 0.531" | 0.130" | 82° | 100 | 98466A009 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.250" | 0.594" | 0.130" | 82° | 100 | 98466A011 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.280" | 0.688" | 0.160" | 82° | 100 | 98466A013 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.320" | 0.781" | 0.180" | 82° | 100 | 98466A029 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.380" | 0.891" | 0.180" | 82° | 50 | 98466A030 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.445" | 1.125" | 0.250" | 82° | 50 | 98466A411 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.140" | 0.390" | 0.110" | 82° | 50 | 94695A170 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.180" | 0.438" | 0.110" | 82° | 50 | 94695A190 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.210" | 0.531" | 0.130" | 82° | 50 | 94695A210 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.250" | 0.593" | 0.130" | 82° | 50 | 94695A230 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.280" | 0.688" | 0.160" | 82° | 25 | 94695A250 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.320" | 0.781" | 0.180" | 82° | 25 | 94695A270 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

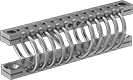

Wire Rope Vibration-Damping Mounts

Absorb vibration from all directions at once to stabilize oscillating equipment such as centrifuges, fans, and tumblers. Unlike many high-capacity mounts, the resilient metal coils flex to withstand shear (horizontal) force.

Unthreaded-Hole Mount

|

Corrosion-Resistant Stainless Steel—Last longer than steel when exposed to water and mild chemicals, such as weak acids used in food production and the acetone found in degreasers.

Overall | Mounting | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap. per Mount, lb. | Deflection @ Cap. | Shear Cap. per Mount, lb. | Deflection @ Shear Cap. | Ht. | Lg. | Wd. | Bar Wd. | Temp. Range, ° F | Fasteners Included | No. of Holes | Hole Dia. | Hole Ctr.-to-Ctr. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 0.13" | 2 | 0.13" | 1" | 3.1" | 1.2" | 0.4" | -150 to 500 | No | 4 | 0.18" | 2.7" | 62225K1 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 0.13" | 3 | 0.13" | 1.4" | 4.4" | 1.6" | 0.5" | -150 to 500 | No | 4 | 0.2" | 3.95" | 62225K11 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 0.13" | 4 | 0.13" | 1.3" | 4.4" | 1.5" | 0.5" | -150 to 500 | No | 4 | 0.2" | 3.95" | 62225K7 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 0.13" | 7 | 0.13" | 1.1" | 4.4" | 1.3" | 0.5" | -150 to 500 | No | 4 | 0.2" | 3.95" | 62225K2 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 0.13" | 12 | 0.13" | 1.5" | 5" | 1.8" | 0.6" | -150 to 500 | No | 4 | 0.26" | 4.5" | 62225K3 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 55 | 0.13" | 19 | 0.13" | 1.3" | 5" | 1.6" | 0.6" | -150 to 500 | No | 4 | 0.26" | 4.5" | 62225K12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 75 | 0.13" | 20 | 0.13" | 1.3" | 5" | 1.7" | 0.6" | -150 to 500 | No | 4 | 0.26" | 4.5" | 62225K4 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 125 | 0.13" | 39 | 0.13" | 1.6" | 5" | 1.8" | 0.6" | -150 to 500 | No | 4 | 0.26" | 4.5" | 62225K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 0.13" | 53 | 0.13" | 1.4" | 5" | 1.6" | 0.6" | -150 to 500 | No | 4 | 0.26" | 4.5" | 62225K5 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 0.13" | 50 | 0.13" | 2.9" | 6.7" | 3.5" | 1" | -150 to 500 | No | 8 | 0.28" | 1.75", 2.63", 1.75" | 62225K14 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 | 0.13" | 60 | 0.13" | 2.8" | 8.5" | 3.3" | 1" | -150 to 500 | No | 8 | 0.28" | 1.75", 2.63", 1.75" | 62225K6 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 0.13" | 105 | 0.13" | 3.5" | 8.5" | 4.1" | 1" | -150 to 500 | No | 8 | 0.33" | 1.75", 2.63", 1.75" | 62225K8 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 900 | 0.13" | 200 | 0.13" | 3.9" | 10.5" | 4.4" | 1" | -150 to 500 | No | 8 | 0.41" | 2.15", 3.23", 2.15" | 62225K9 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

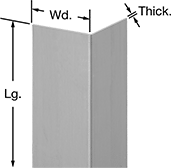

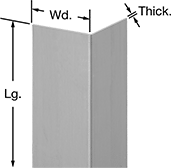

Corner Guards

|

Style 1 |

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

Style 1 |

Metal guards provide more impact protection than plastic guards. They are commonly used in warehouse and manufacturing areas to protect corners on walls and other surfaces from impact.

304 Stainless Steel and 430 Stainless Steel—Stainless steel guards have excellent corrosion resistance. 304 stainless steel is more corrosion resistant than 430 stainless steel.

Adhesive Back—Adhesive-back guards allow for easy installation.

Glue On—Glue-on guards require contact adhesive to adhere to surfaces. Their temperature range depends on the adhesive you use.

4 ft. Long | 8 ft. Long | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Thk. | For Use Outdoors | Temp. Range, ° F | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Adhesive Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1/16" | No | 60 to 120 | 1296A31 | 000000 | 1296A32 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1/16" | No | 60 to 120 | 1296A33 | 000000 | 1296A34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1/16" | No | 60 to 120 | 1296A35 | 000000 | 1296A36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel—Glue On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1/16" | No | — | 1296A11 | 00000 | 1296A12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1/16" | No | — | 1296A13 | 000000 | 1296A14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1/16" | No | — | 1296A15 | 000000 | 1296A16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

430 Stainless Steel—Adhesive Back | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1/16" | No | 60 to 120 | 8144A43 | 00000 | 8144A47 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1/16" | No | 60 to 120 | 8144A45 | 000000 | 8144A48 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1/16" | No | 60 to 120 | 8144A46 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

430 Stainless Steel—Glue On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1/16" | No | — | 8144A33 | 00000 | 8144A35 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1/16" | No | — | 8144A34 | 00000 | 8144A36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1/16" | No | — | 8144A12 | 000000 | 8144A14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

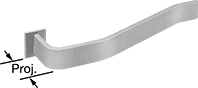

Lockset Bumpers

|

Protect door knobs and other hardware from damage caused by carts, dollies, and other equipment. Mount these bumpers on doors next to, above, below, or over the item you wish to protect. Install them with screws. They are stainless steel for excellent corrosion resistance, making them a good choice for harsh environments. They also have good chemical resistance.

Lg. | Ht. | Thk. | Projection | Material | Appearance | Mounting Fasteners Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unthreaded-Hole Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 1/4" | 1 1/2" | 3/8" | 3 1/4" | Stainless Steel | Dull | Yes | 80205A25 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Door Stops for Sliding Doors

|  |

Style 3 | Style 4 |

Keep sliding doors and panels from damaging walls and door frames. Mount these stops with screws.

Style 3—Styles 2 and 3 mount on the floor.

Style 4—Style 4 mount on walls and ceilings.

304 Stainless Steel—Stainless steel stops have excellent corrosion resistance, making them the best choice for harsh environments. They also have good chemical resistance. They include a rubber bumper, which is abrasion resistant.

Style | Lg. | Wd. | Ht. | For Max. Door Wt., lb. | Material | Pad Material | Mounting Fasteners Included | Mounting Screw Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unthreaded-Hole Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3 1/2" | 3" | 2" | 300 | 304 Stainless Steel | Rubber | No | No. 18 | 10135A68 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 3/4" | 1 1/8" | 1 3/16" | 300 | 304 Stainless Steel | Rubber | Yes | 1/2" | 10135A66 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 9/16" | 1 5/8" | 1 9/16" | 600 | 304 Stainless Steel | Rubber | Yes | 1/2" | 10135A67 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||