Dead Centers

Insert these in your headstock to support your workpiece when machining between centers. Unlike live centers, dead centers don’t spin freely, so they give you a fixed point to stabilize your material. You can also use them in the tailstock to support the end of the workpiece when friction isn’t a concern. Made of through-hardened 52100 alloy steel—a material originally developed for bearings—these centers have exceptional hardness, strength, and wear resistance. That means you'll have to replace them less often than centers made of low-quality steel. You can also apply high-pressure grease on the point to reduce friction and wear.

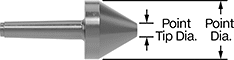

Pipe and tubing centers hold large-diameter, hollow workpieces. Also known as bull-nose centers.

Carbide-tipped hardened steel dead centers have better wear resistance than hardened steel dead centers. They’re ideal for high-volume work and holding highly abrasive and hard materials.

Hardened Steel | Carbide-Tipped Hardened Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Morse Taper Number | Point Dia. | Point Tip Dia. | Point Lg. | Overall Lg. | TIR (Total Indicated Runout) Accuracy | Each | Each | ||

Dead Centers | |||||||||

| 1 | 0.475" | __ | 1 3/16" | 3 5/16" | 0.00005" | 000000 | 0000000 | 00000000 | 0000000 |

| 2 | 0.7" | __ | 1 5/8" | 4 3/16" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 0.938" | __ | 2 1/16" | 5 1/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 1.231" | __ | 2 11/16" | 6 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 5 | 1.748" | __ | 3 5/16" | 8 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 2.494" | __ | 4 1/4" | 11 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 7 | 3.27" | __ | 5" | 15" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

Dead Centers for Pipe and Tubing | |||||||||

| 2 | 2.13" | 1/2" | 2 13/32" | 5" | 0.00005" | 0000000 | 000000 | 000000 | 00 |

| 3 | 2.75" | 1" | 2 33/64" | 5 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 2.75" | 1" | 2 33/64" | 6 9/16" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

| 5 | 3.5" | 1" | 3 11/64" | 8 3/8" | 0.00005" | 0000000 | 000000 | 000000 | 00 |

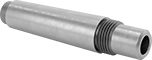

Interchangeable Point Lathe Centers

Mix and match points and bodies to create a lathe center that suits your job. Use an extractor (sold separately) to remove a point and swap in a new one.

Use dead centers in your headstock to support a workpiece when machining between centers. When friction isn’t a concern, you can also use them in the tailstock to support the end of a workpiece. Dead centers don’t spin freely, so they provide a fixed point that stabilizes your workpiece. They can handle heavier loads than live centers. However, under high pressure, they can become lodged in the tailstock. To remove them without damaging your equipment, tighten a hex nut (sold separately) onto the threaded end. Use a wrench to turn the nut against the tailstock and push the center out.

Standard points provide tool clearance for CNC applications, making it easier to machine complex shapes and features. Bull-nose points have a wide head for holding hollow workpieces with large diameters. They’re often used with pipes and tubes. Half points are cut away on one side to hold shafts with keyways, flats, or irregular shapes. They’re used only in dead centers. Extended-tip points are shaped to provide more tool clearance than standard points without adding much length. They’re also used for machining complex shapes and features.

Carbide-tipped points are more wear resistant than hardened steel points. They're a good choice for high-volume operations and for holding hard or highly abrasive materials.

TIR (total indicated runout) is a measure of rotational smoothness—the lower the value, the less wobble a rotating tool will have and the more accurate it will be.

| For Morse Taper No. | Point Dia. | Point Tip Dia. | Material | Each | |

Dead | |||||

|---|---|---|---|---|---|

Standard | |||||

| 3 | 1" | 1/2" | Carbide-Tipped Hardened Steel | 0000000 | 0000000 |

| 4 | 1" | 1/2" | Carbide-Tipped Hardened Steel | 0000000 | 000000 |

| 5 | 1.25" | 5/8" | Carbide-Tipped Hardened Steel | 0000000 | 000000 |

Half | |||||

| 3 | 1" | 1/4" | Hardened Steel | 0000000 | 000000 |

| 4 | 1.13" | 1/4" | Hardened Steel | 000000 | 000000 |

| 5 | 1.5" | 3/8" | Hardened Steel | 0000000 | 000000 |

Precision Live and Dead | |||||

Standard | |||||

| 2, 3 | 1" | __ | Hardened Steel | 0000000 | 000000 |

| 4 | 1.13" | __ | Hardened Steel | 0000000 | 000000 |

| 5 | 1.5" | __ | Hardened Steel | 0000000 | 000000 |

Extended Tip | |||||

| 2, 3 | 0.75" | 3/8" | Hardened Steel | 0000000 | 000000 |

| 4 | 0.8" | 1/2" | Hardened Steel | 0000000 | 000000 |

| 5 | 1.2" | 1/2" | Hardened Steel | 0000000 | 000000 |

Bull Nose | |||||

| 2, 3 | 1.75" | 7/8" | Hardened Steel | 0000000 | 000000 |

| 4 | 2.25" | 1" | Hardened Steel | 0000000 | 000000 |

| 5 | 2.75" | 1 1/2" | Hardened Steel | 0000000 | 000000 |

Center Bodies | Extractors | Hex Nuts | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Morse Taper No. | TIR (Total Indicated Runout) Accuracy | Head Dia. | Thread Size | Material | Each | Each | Pkg. Qty. | Pkg. | |||

Dead | |||||||||||

| 3 | 0.00025" | 3/4" | 7/8"-14 | Hardened Steel | 0000000 | 0000000 | 0000000 | 000000 | 25 | 000000000 | 000000 |

| 4 | 0.00025" | 1" | 1 1/8"-12 | Hardened Steel | 0000000 | 000000 | 0000000 | 00000 | 10 | 000000000 | 00000 |

| 5 | 0.00025" | 1 1/4" | 1 5/8"-12 | Hardened Steel | 0000000 | 000000 | 0000000 | 00000 | 1 | 000000000 | 0000 |

Interchangeable Point Lathe Center Sets

Keep a variety of lathe center points on hand so you always have the right tool for the job. These sets include at least four different points, as well as a lathe center body and a point extractor. Use the point extractor to remove a point from the body and swap in another. You can replace bodies, points, and extractors individually if they become worn or damaged.

Use dead centers in your headstock to support a workpiece when machining between centers. When friction isn’t a concern, you can also use them in the tailstock to support the end of a workpiece. Dead centers don’t spin freely, so they provide a fixed point that stabilizes your workpiece. They can handle heavier loads than live centers. However, under high pressure, they can become lodged in the tailstock. To remove them without damaging your equipment, tighten a hex nut (sold separately) onto the threaded end. Use a wrench to turn the nut against the tailstock and push the center out.

Standard points provide tool clearance for CNC applications, making it easier to machine complex shapes and features. Bull-nose points have a wide head for holding hollow workpieces with large diameters. They’re often used with pipes and tubes. Half points are cut away on one side to hold shafts with keyways, flats, or irregular shapes. They’re used only in dead centers. Extended-tip points are shaped to provide more tool clearance than standard points without adding much length. They’re also used for machining complex shapes and features.

Carbide-tipped points are more wear resistant than hardened steel points. They're a good choice for high-volume operations and for holding hard or highly abrasive materials.

TIR (total indicated runout) is a measure of rotational smoothness. The lower the value, the less wobble a rotating tool will have and the more accurate it will be.

| Morse Taper No. | TIR (Total Indicated Runout) Accuracy | Head Dia. | Thread Size | Shank Lg. | Overall Lg. | Material | No. of Pieces | Includes | Each | |

Dead | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 0.00025" | 3/4" | 7/8"-14 | 3 3/16" | 4 3/8" | Hardened Steel | 7 | 0.75" dia. Hardened Steel Extended-Tip Point 1" dia. Carbide-Tipped Hardened Steel Standard Point 1" dia. Hardened Steel Half Point 1" dia. Hardened Steel Standard Point 1.75" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 000000000 |

| 4 | 0.00025" | 1" | 1 1/8"-12 | 4 1/16" | 5 1/2" | Hardened Steel | 7 | 0.8" dia. Hardened Steel Extended-Tip Point 1" dia. Carbide-Tipped Hardened Steel Standard Point 1.13" dia. Hardened Steel Half Point 1.13" dia. Hardened Steel Standard Point 2.25" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 00000000 |

| 5 | 0.00025" | 1 1/4" | 1 5/8"-12 | 5 3/16" | 6 13/16" | Hardened Steel | 7 | 1.2" dia. Hardened Steel Extended-Tip Point 1.25" dia. Carbide-Tipped Hardened Steel Standard Point 1.5" dia. Hardened Steel Half Point 1.5" dia. Hardened Steel Standard Point 2.75" dia. Hardened Steel Bull-Nose Point Dead Center Body Point Extractor | 0000000 | 00000000 |