Filter by

Mount Type

For Use With

Mixer Speed

Shaft Material

Propeller Material

Overall Height

Direction of Operation

DFARS Specialty Metals

Export Control Classification Number (ECCN)

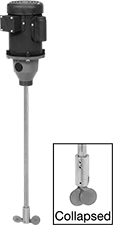

Thread-In Electric Mixers for Drums

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Mount Type | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 29" | 5/8" | 55 | 8 amp/4 amp | 60 | 43" | 39 | Thread In | Totally Enclosed Fan-Cooled (TEFC) | 3484K59 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stand-Mount Electric Mixers for Small Batches

Mixers | Replacement Mixer Propellers | Replacement Motor Brushes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Features | Includes | Cord Lg., ft. | Motor Enclosure Type | Each | Each | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 0.5 amp | 60 | 20 1/4" | 6 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 3522K41 | 0000000 | ——— | 0 | 3522K19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 18" | 3/8" | 5 | 0.5 amp | 60 | 26 1/4" | 7 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 3522K42 | 000000 | ——— | 0 | 3522K19 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 24" | 3/8" | 5 | 0.5 amp | 60 | 32 1/4" | 8 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 3522K43 | 000000 | ——— | 0 | 3522K19 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/40 | 80 to 4,000 | 1 | 2 1/2" | 316 Stainless Steel | 30" | 3/8" | 5 | 0.5 amp | 60 | 38 1/4" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 3522K44 | 000000 | ——— | 0 | 3522K19 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/15 | 40 to 2,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 1.1 amp | 60 | 21" | 8 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 34745K71 | 000000 | 3498K13 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/10 | 5 to 1,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 26 | 0.8 amp | 60 | 25" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 34745K75 | 00000000 | 3498K13 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/10 | 300 to 6,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 0.8 amp | 60 | 21" | 9 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 34745K131 | 000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 40 to 1,200 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 26 | 0.8 amp | 60 | 23" | 12 | Adjustment Dial | 9/16" × 10" Lg. Bar | 6 | Totally Enclosed Nonventilated (TENV) | 3522K46 | 00000000 | 3498K13 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Enclosure Rating | Mount Type | Motor Enclosure Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,750 | 1 | 3 5/8" | 316 Stainless Steel | 48" | 13/16" | 1.5 amp/0.8 amp | 60 | 60 1/16" | 61 | 3" | IP56 | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 1146N22 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Portable Air-Powered Mixers for Small Batches

Shaft | Propellers | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Dia. | Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15" | 1/4" | 1/2 | 300 to 1,200 | 1 | 2 5/8" | 304 Stainless Steel | 2 | 1/4 | NPT | Female | 15.9 ft³/min @ 80 psi | 21 3/4" | 8 | 3489K51 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21" | 1/2" | 1/2 | 300 to 800 | 1 | 5" | 304 Stainless Steel | 10 | 1/4 | NPT | Female | 13.7 ft³/min @ 80 psi | 27 7/16" | 11 | 3489K52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40" | 1/2" | 1/2 | 300 to 450 | 1 | 5" | 304 Stainless Steel | 55 | 1/4 | NPT | Female | 11.9 ft³/min @ 80 psi | 46 7/16" | 18 | 3489K53 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe-Mount Air-Powered Mixers for Small Batches

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | For Pipe OD | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Includes | Mount Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 300 to 1,750 | 1 1/2" | 1 | 4" | 316 Stainless Steel | 12" 16" 20" 24" | 5/8" | 100 | 1/4 | NPT | Female | 25 ft³/min @ 80 psi | 17 13/16" 21 13/16" 25 13/16" 29 13/16" | 12 | Needle Valve | Clamp On | 3477K57 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 300 to 1,750 | 1 1/2" | 2 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 1/4 | NPT | Female | 25 ft³/min @ 80 psi | 37 13/16" | 17 | Needle Valve | Clamp On | 3477K24 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rim-Clamp Electric Mixers for Drums

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Mount Type | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 33 1/8" | 5/8" | 55 | 8.8 amp/4.4 amp | 60 | 44 3/4" | 37 | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 3492K75 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread-In/Rim-Clamp Air-Powered Mixers for Drums

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Max. Clamp Opening | Includes | Mount Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin and Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 30 to 3,000 | 4 | 6" | 304 Stainless Steel | 36" | 1/2" | 55 | 1/4 | NPT | Female | 60 ft³/min @ 80 psi | 42" | 20 | 1" | Needle Valve | Thread In/Clamp On | 35005K85 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

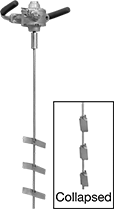

Thread-In Air-Powered Mixers for Drums

Mixers | Replacement Air-Powered Motors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Direct-Drive Motor | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 300 to 1,750 | 1 | 3 3/4" | 316 Stainless Steel | 29" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 39 5/8" | 29 | 35005K64 | 000000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 300 to 1,750 | 3 | 2" | 316 Stainless Steel | 30" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 60" | 35 | 35005K611 | 00000000 | 35005K616 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 3 | 2" | 316 Stainless Steel | 32" | 5/8" | 1/2 | NPT | Female | 59 ft³/min @ 80 psi | 60" | 35 | 35005K613 | 00000000 | 35005K615 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Hazardous Location Rating | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.6 amp/1.8 amp | 60 | 84" | 78 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Clamp On | 3473K69 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Rim-Clamp Electric Mixers for Drums

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Hazardous Location Rating | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 33 1/8" | 5/8" | 55 | 8.8 amp/4.4 amp | 60 | 47 1/2" | 50 | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Clamp On | 3492K88 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Thread-In Electric Mixers for Drums

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Hazardous Location Rating | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 1 | 3 3/4" | 316 Stainless Steel | 29" | 5/8" | 55 | 8 amp/4 amp | 60 | 45 3/4" | 51 | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Thread In | 3484K48 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Mixers for Intermediate Bulk Containers

|  |  |

1 Propeller | 2 Propellers | Replacement Air-Powered Motors |

Mixers | Replacement Air-Powered Motors | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Mount Type | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Forklift Entry | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 600 to 2,000 | 1 | 5" | 316 Stainless Steel | 32" | 1" | 1/4 | NPT | Female | 45 ft³/min @ 80 psi | 38" | 30 | Clamp On | 3528K52 | 000000000 | 3528K66 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 600 to 2,000 | 1 | 6" | 316 Stainless Steel | 32" | 1" | 1/4 | NPT | Female | 45 ft³/min @ 80 psi | 38" | 30 | Clamp On | 3528K53 | 00000000 | 3528K66 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 600 to 2,000 | 2 | 6" | 316 Stainless Steel | 35" | 1" | 1/2 | NPT | Male | 80 ft³/min @ 80 psi | 43" | 41 | Clamp On | 3528K54 | 00000000 | 3528K67 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Without Forklift Entry | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 300 to 3,000 | 2 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Male | 110 ft³/min @ 80 psi | 43" | 56 | Clamp On | 3528K61 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

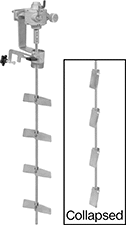

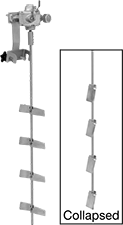

Stand-Mount Air-Powered Mixers for Small Batches

Mixers | Replacement Air-Powered Motors | Replacement Mixer Propellers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Includes | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 500 to 10,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 5 | 1/4 | NPT | Male | 13 ft³/min @ 80 psi | 16 1/2" | 5 | 9/16" × 10" Lg. Bar Needle Valve | 3498K71 | 0000000 | 3498K19 | 0000000 | 3498K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 500 to 10,000 | 1 | 2 1/2" | 316 Stainless Steel | 18" | 3/8" | 5 | 1/4 | NPT | Male | 13 ft³/min @ 80 psi | 22 1/2" | 5 | 9/16" × 10" Lg. Bar Needle Valve | 3498K14 | 000000 | 3498K19 | 000000 | 3498K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 500 to 10,000 | 1 | 2 1/2" | 316 Stainless Steel | 24" | 3/8" | 5 | 1/4 | NPT | Male | 13 ft³/min @ 80 psi | 28 1/2" | 5 | 9/16" × 10" Lg. Bar Needle Valve | 3498K15 | 000000 | 3498K19 | 000000 | 3498K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 500 to 10,000 | 1 | 2 1/2" | 316 Stainless Steel | 30" | 3/8" | 5 | 1/4 | NPT | Male | 13 ft³/min @ 80 psi | 34 1/2" | 5 | 9/16" × 10" Lg. Bar Needle Valve | 3498K16 | 000000 | 3498K19 | 000000 | 3498K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 500 to 7,000 | 1 | 2 1/2" | 316 Stainless Steel | 12" | 3/8" | 26 | 1/4 | NPT | Male | 27 ft³/min @ 80 psi | 16 3/4" | 5 | 9/16" × 10" Lg. Bar Needle Valve | 3498K17 | 000000 | ——— | 0 | 3498K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Mount Type | Motor Enclosure Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 4.4 amp/2.2 amp | 60 | 51" | 48 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K51 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 4.4 amp/2.2 amp | 60 | 63" | 49 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K53 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 32" | 5/8" | 6 amp/3 amp | 60 | 45 1/2" | 53 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K91 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 6 amp/3 amp | 60 | 61 1/2" | 54 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K92 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 5/8" | 6 amp/3 amp | 60 | 73 1/2" | 59 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K93 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 7.4 amp/3.7 amp | 60 | 61 1/2" | 61 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K94 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 3/4" | 8.4 amp/4.2 amp | 60 | 73 1/2" | 68 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K95 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 4" | 316 Stainless Steel | 48" | 3/4" | 10.8 amp/5.4 amp | 60 | 70 1/4" | 66 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 3473K54 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 1.3 amp/0.7 amp | 60 | 51" | 48 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K52 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 3 amp/1.5 amp | 60 | 61 1/2" | 72 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 34945K96 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.8 amp/1.9 amp | 60 | 81 3/4" | 76 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 3473K55 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

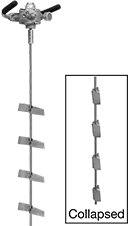

Portable Air-Powered Mixers for Drums

|  |

3 Propellers | 4 Propellers |

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 30 to 3,000 | 3 | 6" | 304 Stainless Steel | 28" | 1/2" | 55 | 1/4 | NPT | Female | 60 ft³/min @ 80 psi | 36" | 16 | Needle Valve | 3476K71 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 30 to 3,000 | 4 | 6" | 304 Stainless Steel | 36" | 1/2" | 55 | 1/4 | NPT | Female | 60 ft³/min @ 80 psi | 41" | 17 | Needle Valve | 3476K73 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rim-Clamp Air-Powered Mixers for Drums

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Max. Clamp Opening | Includes | Mount Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 350 to 1,750 | 1 | 3 3/4" | 316 Stainless Steel | 32" | 5/8" | 55 | 1/4 | NPT | Female | 25 ft³/min @ 80 psi | 38 3/8" | 20 | 5" | — | Clamp On | 35005K66 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 30 to 3,000 | 4 | 6" | 304 Stainless Steel | 36" | 1/2" | 55 | 1/4 | NPT | Female | 60 ft³/min @ 80 psi | 46" | 20 | 2" | Needle Valve | Clamp On | 35005K73 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Mixers for Intermediate Bulk Containers

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Bracket Wd. | Overall Ht. | Wt., lb. | Mount Type | Cord Lg., ft. | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,750 | 1 | 5" | 316 Stainless Steel | 32" | 1" | 275 | 7.4 amp/3.7 amp | 60 | 39 1/2" | 43" | 45 | Clamp On | 10 | Totally Enclosed Fan-Cooled (TEFC) | 1155N5 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,750 | 1 | 6" | 316 Stainless Steel | 32" | 1" | 275 | 12.8 amp/6.4 amp | 60 | 39 1/2" | 45" | 58 | Clamp On | 10 | Totally Enclosed Fan-Cooled (TEFC) | 1155N7 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,750 | 1 | 5" | 316 Stainless Steel | 32" | 1" | 275 | 2 amp/1 amp | 60 | 39 1/2" | 43" | 41 | Clamp On | — | Totally Enclosed Fan-Cooled (TEFC) | 1155N6 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,750 | 1 | 6" | 316 Stainless Steel | 32" | 1" | 275 | 3.4 amp/1.7 amp | 60 | 39 1/2" | 45" | 49 | Clamp On | — | Totally Enclosed Fan-Cooled (TEFC) | 1155N8 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Variable-Speed Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Mount Type | Cord Lg., ft. | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 3.5 amp | 60 | 51" | 50 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 3475K61 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 3.5 amp | 60 | 63" | 51 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 3475K63 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 90 to 1,750 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 4.5 amp | 60 | 63" | 45 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 3475K64 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 90 to 1,750 | 1 | 5 3/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp | 60 | 63" | 55 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 3475K65 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-Mount Electric Mixers for Small Batches

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Cap., gal. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Mount Type | Cord Lg., ft. | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 12" | 5/16" | 50 | 1.6 amp | 60 | 18 7/16" | 10 | 2" | Clamp On | 6 | Totally Enclosed Fan-Cooled (TEFC) | 3497K21 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 18" | 5/16" | 50 | 1.6 amp | 60 | 24 7/16" | 11 | 2" | Clamp On | 6 | Totally Enclosed Fan-Cooled (TEFC) | 3497K16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 24" | 5/16" | 50 | 1.6 amp | 60 | 30 7/16" | 11 | 2" | Clamp On | 6 | Totally Enclosed Fan-Cooled (TEFC) | 3497K17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/20 | 1,550 | 1 | 3" | 316 Stainless Steel | 30" | 5/16" | 50 | 1.6 amp | 60 | 36 7/16" | 11 | 2" | Clamp On | 6 | Totally Enclosed Fan-Cooled (TEFC) | 3497K18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 1 | 4" | 316 Stainless Steel | 32" | 1/2" | 100 | 6.6 amp/3.3 amp | 60 | 42" | 30 | 2" | Clamp On | — | Totally Enclosed Fan-Cooled (TEFC) | 3473K14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,425 | 1 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 8.2 amp/4.1 amp | 50 | 43 3/16" | 47 | 2" | Clamp On | — | Totally Enclosed Fan-Cooled (TEFC) | 3473K25 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 1 | 4" | 316 Stainless Steel | 32" | 5/8" | 100 | 8.8 amp/4.4 amp | 60 | 43 3/16" | 38 | 2" | Clamp On | — | Totally Enclosed Fan-Cooled (TEFC) | 3473K15 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange-Mount Air-Powered Mixers for Tanks

Propellers | Shaft | Air Connection | Flange | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Dia. | Material | Bolt Circle Dia. | No. of Holes | Mounting Hole Dia. | Overall Ht. | Wt., lb. | Includes | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 15" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 20 3/4" | 20 | Needle Valve | Flange | 34705K52 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 32 3/4" | 25 | Needle Valve | Flange | 34705K53 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 55 3/4" | 26 | Needle Valve | Flange | 34705K54 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 27" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 34 7/16" | 34 | Needle Valve | Flange | 34705K64 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 55 7/16" | 38 | Needle Valve | Flange | 34705K65 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 67 7/16" | 41 | Needle Valve | Flange | 34705K66 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 300 to 1,750 | 1 | 10" | 316 Stainless Steel | 48" | 1" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 55 7/16" | 44 | Needle Valve | Flange | 34705K76 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Mixers with Batch Cans

Mixers | Replacement Air-Powered Motors | Replacement Batch Cans with Lid | Replacement Lids | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap., gal. | Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Each | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Container with Plastic Spigot | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3/4 | 0 to 1,750 | 1 | 5" | 316 Stainless Steel | 10" | 1/2" | 1/4 | NPT | Female | 20 ft³/min @ 80 psi | 17" | 3513K13 | 0000000 | 3513K101 | 0000000 | 3513K51 | 0000000 | 3513K32 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 3/4 | 0 to 1,750 | 1 | 5" | 316 Stainless Steel | 12" | 1/2" | 1/4 | NPT | Female | 20 ft³/min @ 80 psi | 22 1/2" | 3513K14 | 000000 | 3513K101 | 000000 | 3513K52 | 000000 | 3513K36 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel Container with 316 Stainless Steel 3/4 NPT Ball Valve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3/4 | 0 to 1,750 | 1 | 5" | 316 Stainless Steel | 10" | 1/2" | 1/4 | NPT | Female | 20 ft³/min @ 80 psi | 16 13/32" | 3513K23 | 00000000 | 3513K101 | 000000 | 3513K53 | 000000 | 3513K39 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 3/4 | 0 to 1,750 | 1 | 5" | 316 Stainless Steel | 12" | 1/2" | 1/4 | NPT | Female | 20 ft³/min @ 80 psi | 21" | 3513K24 | 00000000 | 3513K101 | 000000 | 3513K54 | 000000 | 3513K43 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-Mount Air-Powered Mixers for Tanks

Mixers | Replacement Air-Powered Motors | Replacement Mixer Propellers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Max. Clamp Opening | Includes | Mount Type | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 33" | 28 | 1 7/8" | Needle Valve | Clamp On | 34685K54 | 000000000 | 34685K111 | 0000000 | 34685K124 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 42" | 28 | 1 7/8" | Needle Valve | Clamp On | 34685K55 | 00000000 | 34685K111 | 000000 | 34685K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 54" | 37 | 1 7/8" | Needle Valve | Clamp On | 34685K56 | 00000000 | 34685K111 | 000000 | 34685K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 33" | 30 | 1 7/8" | Needle Valve | Clamp On | 34685K64 | 00000000 | 34685K111 | 000000 | 34685K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 42" | 30 | 1 7/8" | Needle Valve | Clamp On | 34685K65 | 00000000 | 34685K111 | 000000 | 34685K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 54" | 39 | 1 7/8" | Needle Valve | Clamp On | 34685K66 | 00000000 | 34685K111 | 000000 | 34685K124 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 27" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 34 5/16" | 35 | 1 7/8" | Needle Valve | Clamp On | 34685K75 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 43 5/16" | 39 | 1 7/8" | Needle Valve | Clamp On | 34685K76 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 55 5/16" | 40 | 1 7/8" | Needle Valve | Clamp On | 34685K77 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 67 5/16" | 52 | 1 7/8" | Needle Valve | Clamp On | 34685K78 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 43 5/16" | 41 | 1 7/8" | Needle Valve | Clamp On | 34685K85 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 55 5/16" | 42 | 1 7/8" | Needle Valve | Clamp On | 34685K86 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 67 5/16" | 55 | 1 7/8" | Needle Valve | Clamp On | 34685K87 | 00000000 | 34685K112 | 00000000 | 34685K125 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||