About Dock Levelers and Dock Plates

More

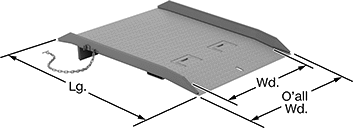

Dock Levelers

Permanently attach these levelers to a dock to bridge the gap between the edge of the dock and a truck. Use them when loading and unloading with forklifts, pallet trucks, and hand trucks. Each leveler has a deck plate, a hinged lip plate, and two bumpers that are attached to bumper blocks. Dual extension springs act as a counterbalance to aid the leveler as it mechanically lifts the lip plate onto the truck bed; the springs return the lip plate to its original position when the truck pulls away. The plates have a diamond surface texture for positive traction.

To install, weld levelers to a dock face with a minimum 8" wide steel channel embedded into concrete at the dock edge. If the dock edge does not have an 8" wide steel channel, use the optional installation kit (sold separately) for bolt-on mounting.

Style A include a lifting hook to raise the lip plate and come with a hanger for storing the lifting hook when not in use.

Style B have a self-storing handle instead of a lifting hook. Pull the handle back about 50° and then return it to its original vertical position to lift the lip plate. There's no need to bend, push, or lean.

Note: To determine load, take the gross weight of equipment, add typical load weight, and then multiply by two.

Bumper | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Ht. Differential | Capacity, lbs. | Lg. | Wd. | Overall Wd. | Number of Bumpers | Material | Block Material | Lg. | Wd. | Thick. | Each | |

| A | ±5" | 20,000 | 27 3/4" | 66" | 102" | 2 | Rubber | Steel | 13" | 12" | 4" | 0000000 | 000000000 |

| A | ±5" | 20,000 | 27 3/4" | 72" | 108" | 2 | Rubber | Steel | 13" | 12" | 4" | 0000000 | 00000000 |

| B | ±5" | 20,000 | 27 3/4" | 66" | 102" | 2 | Rubber | Steel | 13" | 12" | 4" | 0000000 | 00000000 |

| B | ±5" | 20,000 | 27 3/4" | 72" | 108" | 2 | Rubber | Steel | 13" | 12" | 4" | 0000000 | 00000000 |

| Optional Installation Kit (includes ramp plate, 17 anchor bolts, and four angles) | 0000000 | Each | 0000000 |

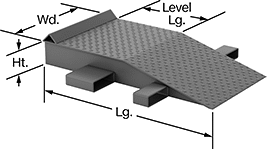

Wheel Risers

Raise vehicles up for maintenance jobs or elevate them to dock height for loading and unloading. These risers have a diamond surface texture for positive traction.

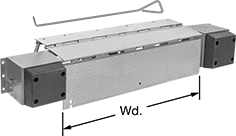

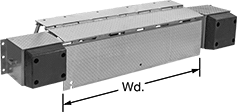

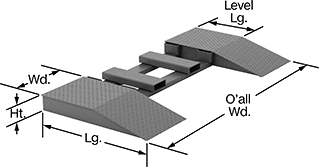

Wheel Risers with Forklift Pockets

Pockets make it easy to move these risers with a forklift. Use them to raise vehicles up for maintenance jobs or bring vehicles up to dock height for loading and unloading. The diamond surface texture creates good traction, so tires won't slip or spin.

A roll-off lip stops tires from going too far and accidentally falling off the riser.

For Maximum Fork | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Risers | Height | Capacity, lbs. | Width | Height | Level Length | Length | Width | Overall Width | Material | Features | Specifications Met | Each | |

| 1 | 6 1/4" | 40,000 | 7 1/2" | 2 1/2" | 24" | 48" | 24" | __ | Painted Steel | Forklift Pockets, Roll Off Lip | ANSI B56.1 | 0000000 | 0000000 |

| 2 | 6 1/4" | 40,000 | 7 1/2" | 2 1/2" | 24" | 48" | 24" | 101 1/8" | Painted Steel | Forklift Pockets | ANSI B56.1 | 0000000 | 00000000 |

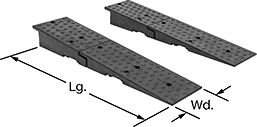

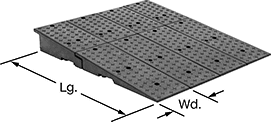

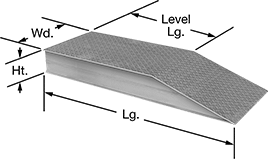

Low-Height Vehicle Ramps

Create a smooth transition for driving forklifts over curbs and into shipping containers. Often used for loading or unloading, these vehicle ramps have a diamond texture on the surface to give wheels traction.

Rubber ramps are best for occasional use, since fully loaded forklifts will erode their surface over time. Lock them together with the built-in connectors to make a solid ramp, or separate them to use as wheel tracks.

Steel ramps are strong enough to hold up to frequent use. A lip on each side keeps wheels from running off the edge. To keep them from shifting, lock them to your container with the included chains. These ramps have loops built into the top, so you can pick them up and move them with your forklift. The loops fold flat when they’re not in use.

Note: Ramps that have OSHA specifications listed meet dimensional and construction standards. Check local, state, and federal codes, including OSHA, for safe set up and operating practices.

Lip | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Ramps Included | Max. Ht. Differential | Capacity, lbs. | Lg., ft. | Wd. | Overall Wd. | Plate Thick. | Material | Color | Features | Includes | Specifications Met | Each | |

| 1 | ±11" | 20,000 | 6 | 66" | 72" | 3/8" | Painted Steel | Blue | Forklift Loops | Locking Chains | ANSI MH 30.2, OSHA Compliant 29 CFR 1910.26 | 00000000 | 000000000 |