Filter by

System of Measurement

Diameter

Hole Diameter

End Shape

Shaft Type

Fastener Head Type

End Type

Material

Hardness

Wall Thickness

Double Shear Breaking Strength

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Passivation

Pin Type

Minimum Hardness

Performance

V Width

Application

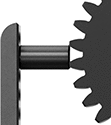

Slotted Spring Pins

Lg., mm | For Hole Dia., mm | Wall Thk., mm | Double Shear Breaking Strength, lbf | Min. Hardness | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Spring Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

13 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 5 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70 | 13 | 1.2 | 14,800 | Rockwell C42 | DIN 7346, ISO 13337 | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||